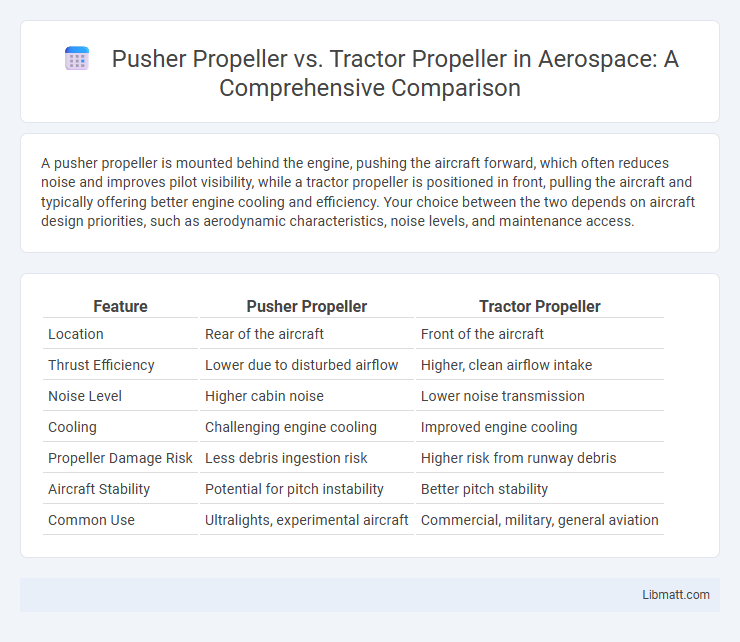

A pusher propeller is mounted behind the engine, pushing the aircraft forward, which often reduces noise and improves pilot visibility, while a tractor propeller is positioned in front, pulling the aircraft and typically offering better engine cooling and efficiency. Your choice between the two depends on aircraft design priorities, such as aerodynamic characteristics, noise levels, and maintenance access.

Table of Comparison

| Feature | Pusher Propeller | Tractor Propeller |

|---|---|---|

| Location | Rear of the aircraft | Front of the aircraft |

| Thrust Efficiency | Lower due to disturbed airflow | Higher, clean airflow intake |

| Noise Level | Higher cabin noise | Lower noise transmission |

| Cooling | Challenging engine cooling | Improved engine cooling |

| Propeller Damage Risk | Less debris ingestion risk | Higher risk from runway debris |

| Aircraft Stability | Potential for pitch instability | Better pitch stability |

| Common Use | Ultralights, experimental aircraft | Commercial, military, general aviation |

Introduction to Propeller Configurations

Pusher and tractor propeller configurations differ primarily in the placement relative to the engine and airflow direction, with tractor propellers mounted at the front, pulling the aircraft, and pusher propellers positioned at the rear, pushing it forward. Tractor propellers typically offer improved engine cooling and reduced prop-wash turbulence on the airframe, while pusher propellers can enhance visibility and reduce noise for occupants. The choice between these configurations impacts aerodynamic efficiency, aircraft stability, and structural design considerations.

What is a Tractor Propeller?

A tractor propeller is an aircraft propeller mounted at the front of the engine, pulling the aircraft through the air. It is designed to provide efficient thrust by operating in undisturbed airflow, enhancing engine cooling and aerodynamic performance. Commonly used in most conventional propeller-driven aircraft, the tractor propeller offers improved stability and control compared to pusher configurations.

What is a Pusher Propeller?

A pusher propeller is a type of aircraft propeller positioned behind the engine, pushing the aircraft forward by generating thrust from the rear. Unlike tractor propellers that pull the aircraft, pusher propellers improve aerodynamics and reduce noise in the cabin by minimizing airflow disruption over the fuselage. You benefit from smoother airflow and potential efficiency gains when choosing a pusher propeller design in certain aircraft configurations.

Aerodynamic Efficiency Comparison

Pusher propellers are positioned behind the engine, reducing airflow disruption over the airframe and often resulting in slightly higher propulsive efficiency by minimizing slipstream interference. Tractor propellers, located in front of the engine, generally provide better cooling and smoother airflow into the propeller disc, which can improve thrust at lower speeds but may suffer from increased drag due to disturbed airflow around the aircraft body. Your choice between pusher and tractor propeller configurations significantly impacts aerodynamic efficiency depending on aircraft design, speed regime, and mission profile.

Impact on Aircraft Performance

Pusher propellers improve aircraft performance by reducing aerodynamic drag and enhancing pilot visibility due to their rear placement, which also contributes to quieter cabin environments. Tractor propellers offer superior cooling for the engine and generally provide better thrust efficiency at lower speeds, improving takeoff and climb performance. The choice between pusher and tractor configurations significantly influences overall aircraft efficiency, handling characteristics, and noise levels.

Noise and Vibration Differences

Pusher propellers generally produce higher noise levels and increased vibration due to airflow turbulence from the fuselage and wing structures, which disrupts the propeller's smooth operation. Tractor propellers benefit from cleaner airflow, resulting in reduced noise and smoother engine performance with less vibration. This makes tractor configurations preferable in applications where noise reduction and vibration minimization are critical.

Maintenance and Accessibility

Pusher propellers typically require more maintenance due to their rear-mounted position, which exposes them to debris and makes access more challenging compared to tractor propellers. Tractor propellers, mounted at the front of the aircraft, offer easier accessibility for inspection, cleaning, and repairs, reducing downtime and maintenance costs. The front placement of tractor propellers also simplifies routine checks and enhances operational reliability.

Safety Considerations

Pusher propellers reduce the risk of injuries on the ground by positioning the rotating blades behind the aircraft structure, lowering the chance of accidental contact during boarding or maintenance. Tractor propellers, located at the front, offer better airflow over control surfaces, enhancing handling and stability, which contributes to safer flight characteristics, especially at low speeds. Engine cooling and propeller efficiency also impact safety; tractor configurations often provide improved engine cooling, reducing the likelihood of overheating-related failures.

Applications and Common Use Cases

Pusher propellers are commonly used in aircraft designs requiring unobstructed forward visibility and reduced noise for passengers, such as drones, amphibious planes, and some experimental aircraft. Tractor propellers dominate in commercial aviation and general aviation due to better cooling of the engine and improved airflow efficiency, making them ideal for passenger planes, cargo aircraft, and light sport aircraft. Both configurations have niche applications, with pushers favored in specialized scenarios where aerodynamic cleanliness and safety are prioritized, while tractors excel in traditional, high-performance flight operations.

Choosing the Right Propeller Configuration

Selecting the right propeller configuration depends on factors like aircraft design and performance goals. Pusher propellers, mounted behind the engine, typically offer improved aerodynamics and unobstructed pilot visibility, enhancing efficiency for certain aircraft. Tractor propellers, positioned in front of the engine, provide better engine cooling and are generally more stable, making them a reliable choice for various flight conditions and your specific operational needs.

Pusher Propeller vs Tractor Propeller Infographic

libmatt.com

libmatt.com