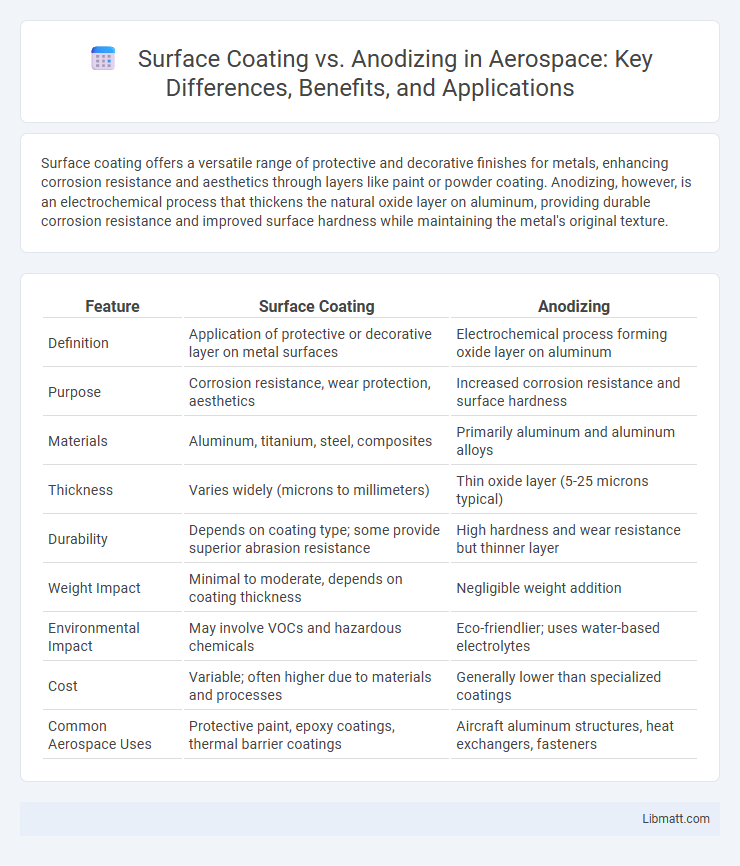

Surface coating offers a versatile range of protective and decorative finishes for metals, enhancing corrosion resistance and aesthetics through layers like paint or powder coating. Anodizing, however, is an electrochemical process that thickens the natural oxide layer on aluminum, providing durable corrosion resistance and improved surface hardness while maintaining the metal's original texture.

Table of Comparison

| Feature | Surface Coating | Anodizing |

|---|---|---|

| Definition | Application of protective or decorative layer on metal surfaces | Electrochemical process forming oxide layer on aluminum |

| Purpose | Corrosion resistance, wear protection, aesthetics | Increased corrosion resistance and surface hardness |

| Materials | Aluminum, titanium, steel, composites | Primarily aluminum and aluminum alloys |

| Thickness | Varies widely (microns to millimeters) | Thin oxide layer (5-25 microns typical) |

| Durability | Depends on coating type; some provide superior abrasion resistance | High hardness and wear resistance but thinner layer |

| Weight Impact | Minimal to moderate, depends on coating thickness | Negligible weight addition |

| Environmental Impact | May involve VOCs and hazardous chemicals | Eco-friendlier; uses water-based electrolytes |

| Cost | Variable; often higher due to materials and processes | Generally lower than specialized coatings |

| Common Aerospace Uses | Protective paint, epoxy coatings, thermal barrier coatings | Aircraft aluminum structures, heat exchangers, fasteners |

Introduction to Surface Coating and Anodizing

Surface coating involves applying a protective or decorative layer onto a material's surface to enhance durability, corrosion resistance, and aesthetic appeal. Anodizing is an electrochemical process that thickens and toughens the natural oxide layer on metals like aluminum, improving wear resistance and preventing oxidation. Both techniques serve to protect and extend the lifespan of metal components but differ in application methods and performance characteristics.

Fundamental Differences Between Surface Coating and Anodizing

Surface coating involves applying an external layer of material, such as paint or powder, to enhance corrosion resistance, appearance, and durability, while anodizing is an electrochemical process that thickens and strengthens the natural oxide layer on metal surfaces, particularly aluminum. Surface coatings can vary widely in composition and thickness, offering flexibility in color and texture, whereas anodizing produces a uniform, integral oxide film that improves hardness and wear resistance without adding material thickness. The fundamental difference lies in surface coating being an additive process that deposits a protective layer, whereas anodizing is a transformative process altering the metal surface's chemistry and structure.

Processes Involved in Surface Coating

Surface coating involves applying a protective or decorative layer onto a material's surface through processes such as spraying, dipping, or electroplating, which enhances corrosion resistance, wear protection, and aesthetic appeal. Unlike anodizing, which uses an electrochemical process to thicken the natural oxide layer of metals like aluminum, surface coating often relies on physical or chemical deposition of paints, powders, or films. Your choice between surface coating and anodizing depends on the desired durability, appearance, and environmental resistance requirements of the application.

How Anodizing Works: Step-by-Step

Anodizing involves immersing the aluminum workpiece in an acid electrolyte bath and passing an electric current through it, causing a controlled oxidation process that forms a durable oxide layer on the surface. This oxide layer is porous initially, allowing for dyeing and sealing to enhance corrosion resistance and aesthetic appeal. Unlike surface coating methods such as painting or powder coating, anodizing creates a permanent, non-peeling surface integral to the metal substrate, improving hardness and wear resistance.

Material Compatibility: Surface Coating vs Anodizing

Surface coating offers broad material compatibility, including metals, plastics, and composites, allowing customized protection and aesthetics across various substrates. Anodizing is primarily suitable for aluminum and its alloys, enhancing corrosion resistance and surface hardness through an electrochemical process. Your choice depends on the base material's compatibility and the desired durability and finish.

Durability and Performance Comparison

Surface coating provides a versatile layer of protection against corrosion and wear, often enhancing aesthetic appeal with various finishes. Anodizing, however, creates a durable oxide layer that is highly resistant to abrasion and corrosion, making it ideal for extreme environments and long-term performance. Your choice depends on whether you prioritize thicker, customizable coatings or a hard, integrated surface treatment that maintains the metal's natural properties.

Cost Analysis: Surface Coating vs Anodizing

Surface coating generally offers a lower upfront cost compared to anodizing, making it suitable for budget-conscious projects or large-scale applications where initial expense matters. Anodizing, while often more expensive initially due to its electrochemical process, provides superior durability, corrosion resistance, and long-term cost savings by reducing maintenance and replacement needs. Assessing your project's lifecycle costs reveals that anodizing can be more economical over time despite higher starting costs, especially for components exposed to harsh environments.

Environmental Impact of Both Methods

Surface coating processes often involve the use of volatile organic compounds (VOCs) and hazardous chemicals, which can contribute to air and water pollution if not properly managed. Anodizing is generally considered more environmentally friendly as it produces a stable oxide layer without the use of toxic paints or solvents, though it does generate wastewater containing heavy metals that require treatment. By choosing anodizing, you reduce harmful emissions, but careful handling and disposal of byproducts are essential to minimize ecological impact.

Industrial Applications and Use Cases

Surface coating provides versatile protection against corrosion, wear, and chemical damage in industries such as automotive, aerospace, and electronics, enhancing the durability of components like engine parts and circuit boards. Anodizing, primarily applied to aluminum and its alloys, delivers a hard, corrosion-resistant, and aesthetically appealing oxide layer widely used in architectural panels, marine equipment, and consumer electronics. Both methods improve surface properties but anodizing is preferred for lightweight structural applications requiring enhanced hardness and corrosion resistance without added material thickness.

Choosing the Right Method: Key Considerations

Selecting between surface coating and anodizing depends on factors such as corrosion resistance, durability, aesthetic requirements, and environmental impact. Surface coating offers versatility with various materials like paint or powder coatings suitable for different textures and colors, while anodizing enhances aluminum's natural oxide layer for superior hardness and corrosion protection. Cost-effectiveness and maintenance needs also influence the choice, with anodizing typically providing longer-lasting protection and coatings allowing easier reapplication or repair.

surface coating vs anodizing Infographic

libmatt.com

libmatt.com