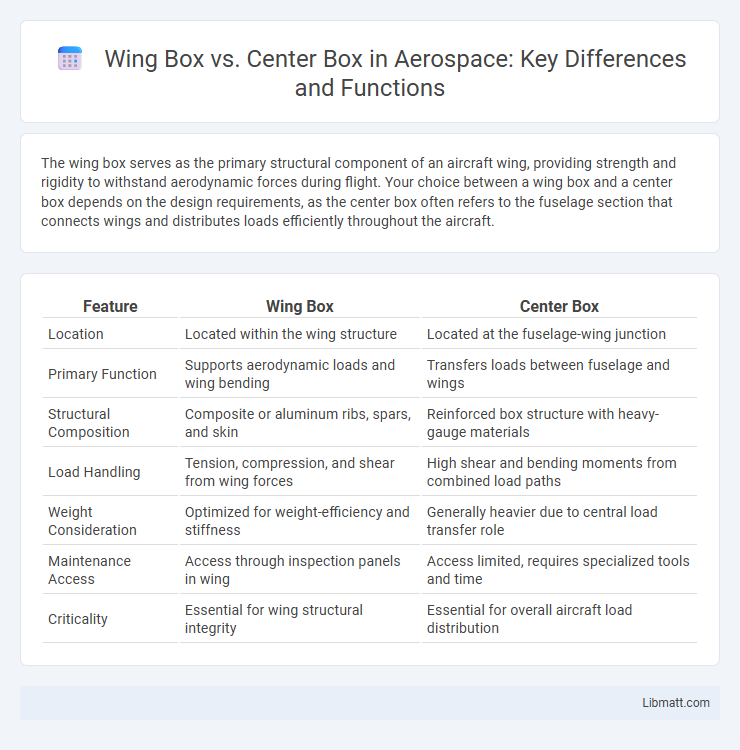

The wing box serves as the primary structural component of an aircraft wing, providing strength and rigidity to withstand aerodynamic forces during flight. Your choice between a wing box and a center box depends on the design requirements, as the center box often refers to the fuselage section that connects wings and distributes loads efficiently throughout the aircraft.

Table of Comparison

| Feature | Wing Box | Center Box |

|---|---|---|

| Location | Located within the wing structure | Located at the fuselage-wing junction |

| Primary Function | Supports aerodynamic loads and wing bending | Transfers loads between fuselage and wings |

| Structural Composition | Composite or aluminum ribs, spars, and skin | Reinforced box structure with heavy-gauge materials |

| Load Handling | Tension, compression, and shear from wing forces | High shear and bending moments from combined load paths |

| Weight Consideration | Optimized for weight-efficiency and stiffness | Generally heavier due to central load transfer role |

| Maintenance Access | Access through inspection panels in wing | Access limited, requires specialized tools and time |

| Criticality | Essential for wing structural integrity | Essential for overall aircraft load distribution |

Introduction to Aircraft Structural Components

The wing box is a primary structural component of an aircraft, designed to carry aerodynamic loads and distribute them efficiently across the wings, serving as the main load-bearing structure. The center box connects the wings to the fuselage, providing critical support and transmitting forces between the wing and aircraft body while maintaining structural integrity. Both components are essential for ensuring the aircraft's strength, stability, and performance during flight operations.

Defining the Wing Box

The wing box is the primary structural component of an aircraft wing, consisting of spars, ribs, and skin that form a strong, hollow box to resist aerodynamic forces and torsional loads. It differs from the center box, which connects the wings to the fuselage and distributes loads between the wings and the aircraft body. The wing box is critical for maintaining wing integrity and ensuring flight stability by efficiently managing bending moments and shear forces.

Understanding the Center Box

The center box is a crucial structural component in aircraft wing design, providing the primary load-bearing capacity and connecting the wings to the fuselage. Unlike the wing box, which extends along the wing's span and carries aerodynamic stresses, the center box absorbs significant bending and torsional forces during flight. Understanding the center box helps you appreciate how its reinforced design ensures overall wing integrity and stability.

Key Structural Differences

The wing box features large spars and ribs designed to manage bending and torsional loads distributed along the wingspan, enhancing aerodynamic efficiency and structural integrity. In contrast, the center box comprises the fuselage-adjacent section with reinforced bulkheads and shear webs that bear concentrated loads from engine mounts and landing gear attachments. Key structural differences include the wing box's role in load transfer across the wing structure versus the center box's function as a rigid, load-bearing core integrating wing and fuselage stresses.

Functions and Roles in Aircraft Design

The wing box serves as the primary structural component that carries aerodynamic loads and transfers them between the wings and fuselage, ensuring overall aircraft stability. The center box connects the wing box to the fuselage, providing crucial support for engine mounts, landing gear attachments, and distributing stresses during flight maneuvers. Your understanding of these roles highlights how both components work together to maintain structural integrity and safety in aircraft design.

Materials Used in Wing and Center Boxes

Wing boxes commonly utilize high-strength aluminum alloys and composite materials such as carbon fiber reinforced polymers (CFRP) to balance weight reduction and structural integrity. Center boxes demand materials with superior fatigue resistance and stiffness, often incorporating titanium alloys and advanced composites to endure higher stress concentrations at wing roots. Your choice of materials impacts both the aircraft's performance and durability, with wing boxes favoring lighter composites and center boxes relying on metal composites for critical load-bearing capabilities.

Load Distribution: Wing Box vs. Center Box

The wing box primarily handles aerodynamic loads from the wings, distributing lift forces efficiently along the wing span and into the fuselage. In contrast, the center box acts as the central structural component connecting wings, managing torsional and bending loads while transferring these forces to the fuselage. Understanding the differences in load distribution between the wing box and center box is crucial for optimizing your aircraft's structural integrity and performance.

Maintenance and Inspection Considerations

Maintenance and inspection of wing boxes require thorough checks for fatigue cracks, corrosion, and fastener integrity due to their critical role in load distribution during flight. Center boxes demand careful attention to damage from impact and stress concentrations, with access often limited, necessitating specialized tools and techniques for effective inspection. Ensuring your aircraft's structural integrity involves tailored procedures for both components to prevent failure and extend operational lifespan.

Impact on Aircraft Performance and Safety

The wing box provides crucial structural integrity by distributing aerodynamic loads across the wings, significantly enhancing lift efficiency and flight stability. In contrast, the center box links the wings to the fuselage, playing a vital role in load transfer and overall airframe durability, which directly impacts safety during high-stress maneuvers and turbulence. Efficient design and materials in both the wing box and center box reduce weight while maintaining strength, optimizing fuel consumption and improving the aircraft's performance and safety margins.

Future Trends in Box Structure Designs

Future trends in wing box vs center box designs emphasize lightweight materials like carbon fiber composites to enhance fuel efficiency and structural strength. Advanced manufacturing techniques such as additive manufacturing enable complex geometries that optimize load distribution and reduce weight. Your aircraft's structural performance will benefit from these innovations, balancing durability with aerodynamic efficiency.

Wing box vs Center box Infographic

libmatt.com

libmatt.com