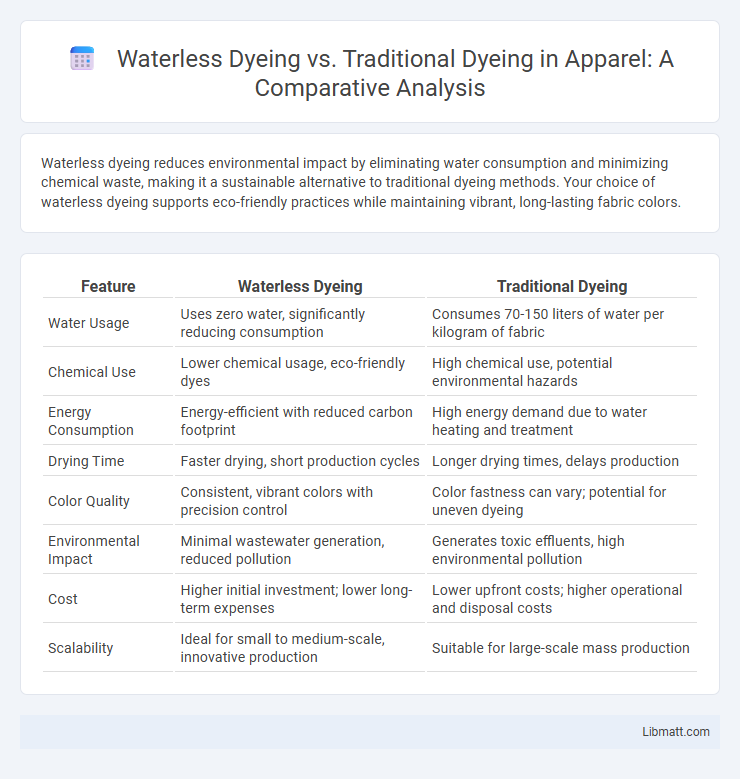

Waterless dyeing reduces environmental impact by eliminating water consumption and minimizing chemical waste, making it a sustainable alternative to traditional dyeing methods. Your choice of waterless dyeing supports eco-friendly practices while maintaining vibrant, long-lasting fabric colors.

Table of Comparison

| Feature | Waterless Dyeing | Traditional Dyeing |

|---|---|---|

| Water Usage | Uses zero water, significantly reducing consumption | Consumes 70-150 liters of water per kilogram of fabric |

| Chemical Use | Lower chemical usage, eco-friendly dyes | High chemical use, potential environmental hazards |

| Energy Consumption | Energy-efficient with reduced carbon footprint | High energy demand due to water heating and treatment |

| Drying Time | Faster drying, short production cycles | Longer drying times, delays production |

| Color Quality | Consistent, vibrant colors with precision control | Color fastness can vary; potential for uneven dyeing |

| Environmental Impact | Minimal wastewater generation, reduced pollution | Generates toxic effluents, high environmental pollution |

| Cost | Higher initial investment; lower long-term expenses | Lower upfront costs; higher operational and disposal costs |

| Scalability | Ideal for small to medium-scale, innovative production | Suitable for large-scale mass production |

Introduction to Textile Dyeing Methods

Waterless dyeing uses supercritical carbon dioxide to color fabrics, eliminating water usage and reducing environmental impact, while traditional dyeing relies heavily on water-intensive processes with synthetic dyes. Your choice between these methods influences energy consumption, chemical use, and wastewater management in textile production. Advancements in waterless technology offer sustainable alternatives to conventional dyeing, aligning with eco-friendly manufacturing goals.

Overview of Traditional Dyeing Processes

Traditional dyeing processes involve immersing textiles in water-based dye baths where colors penetrate fibers through absorption and chemical bonding. These methods consume significant amounts of water and energy, often resulting in wastewater containing dyes and chemicals that require treatment. Your choice of dyeing impacts environmental sustainability and operational costs due to the resource-intensive nature of traditional techniques.

What is Waterless Dyeing?

Waterless dyeing is an innovative textile coloring process that eliminates the need for water, using supercritical carbon dioxide to dissolve and apply dye molecules directly to fabrics. This method significantly reduces water consumption and chemical waste compared to traditional dyeing techniques, which require large volumes of water for dye baths and rinsing. Your choice of waterless dyeing supports sustainable manufacturing by minimizing environmental impact and conserving vital water resources.

Environmental Impact: Waterless vs Traditional

Waterless dyeing significantly reduces water consumption compared to traditional dyeing, which uses thousands of liters per kilogram of fabric, leading to severe water pollution and resource depletion. This innovative process also minimizes chemical runoff, lowering the environmental footprint and preventing harmful contaminants from entering waterways. By choosing waterless dyeing, you support sustainable practices that conserve water and protect ecosystems from toxic waste associated with conventional methods.

Resource Consumption and Efficiency

Waterless dyeing significantly reduces resource consumption by eliminating the need for large volumes of water and minimizing chemical use, resulting in lower wastewater generation compared to traditional dyeing. The efficiency of waterless dyeing is enhanced through faster processing times and reduced energy requirements, making it a more sustainable option for textile production. Your choice of waterless dyeing can lead to substantial savings in water and energy, promoting eco-friendly manufacturing practices.

Color Quality and Fabric Compatibility

Waterless dyeing techniques produce vibrant, consistent colors with enhanced penetration, minimizing color bleeding and fading compared to traditional water-based dyeing. This method is highly compatible with synthetic fabrics such as polyester, allowing precise control over dye uptake and uniformity. Traditional dyeing remains versatile for natural fibers like cotton but often involves uneven color distribution and requires extensive water usage.

Industrial Applications and Scalability

Waterless dyeing technology offers significant advantages in industrial applications by reducing water consumption and chemical waste, making it ideal for large-scale textile manufacturing. Traditional dyeing methods remain widespread due to established infrastructure and cost-efficiency, but they face challenges in scalability due to environmental regulations and high water usage. Your choice between these methods impacts sustainability initiatives and operational scalability in textile production.

Financial Considerations: Cost Comparison

Waterless dyeing significantly reduces water and energy expenses compared to traditional dyeing, leading to lower operational costs for manufacturers. While initial investments in waterless dyeing technology may be higher, your long-term savings come from decreased resource consumption and wastewater treatment fees. Traditional dyeing often incurs higher costs from extensive water use and environmental compliance, impacting overall financial efficiency.

Innovations and Future Trends in Dyeing

Waterless dyeing technologies, such as supercritical CO2 dyeing, significantly reduce water consumption and chemical waste, addressing sustainability challenges in the textile industry. Innovations like digital inkjet dyeing and enzyme-based treatments further enhance precision and environmental friendliness by minimizing resource usage and pollution. Future trends emphasize integrating AI-driven process optimization and circular dyeing systems to achieve zero-waste production and meet stringent ecological regulations.

Choosing the Right Dyeing Method

Choosing the right dyeing method depends on factors such as environmental impact, cost-efficiency, and fabric type. Waterless dyeing reduces water usage by up to 90%, offering a sustainable alternative to traditional methods that consume vast amounts of water and chemicals. Your decision should balance ecological benefits with fabric compatibility and production scale to optimize quality and sustainability.

Waterless Dyeing vs Traditional Dyeing Infographic

libmatt.com

libmatt.com