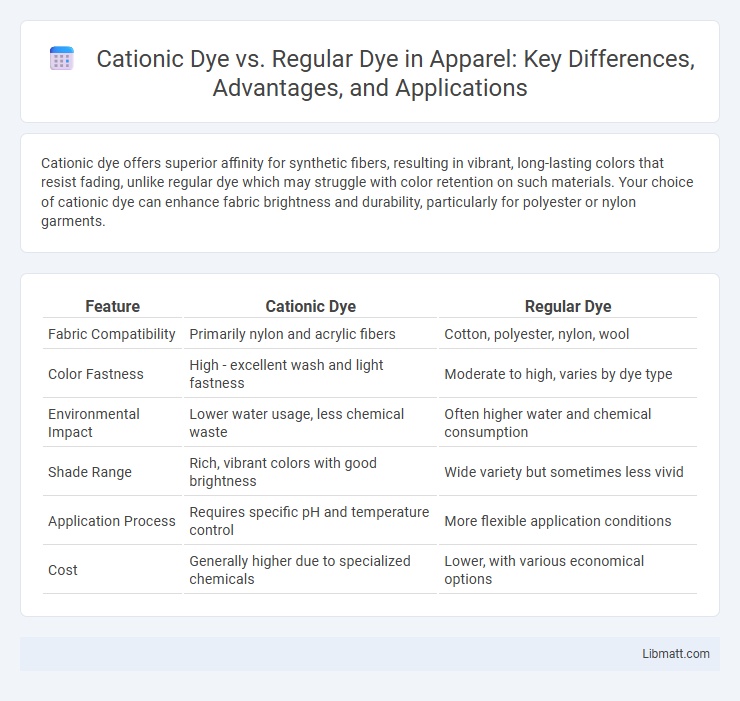

Cationic dye offers superior affinity for synthetic fibers, resulting in vibrant, long-lasting colors that resist fading, unlike regular dye which may struggle with color retention on such materials. Your choice of cationic dye can enhance fabric brightness and durability, particularly for polyester or nylon garments.

Table of Comparison

| Feature | Cationic Dye | Regular Dye |

|---|---|---|

| Fabric Compatibility | Primarily nylon and acrylic fibers | Cotton, polyester, nylon, wool |

| Color Fastness | High - excellent wash and light fastness | Moderate to high, varies by dye type |

| Environmental Impact | Lower water usage, less chemical waste | Often higher water and chemical consumption |

| Shade Range | Rich, vibrant colors with good brightness | Wide variety but sometimes less vivid |

| Application Process | Requires specific pH and temperature control | More flexible application conditions |

| Cost | Generally higher due to specialized chemicals | Lower, with various economical options |

Introduction to Textile Dyes

Cationic dyes are positively charged molecules that have a strong affinity for negatively charged fibers such as acrylic, resulting in vibrant, long-lasting colors in textile applications. Regular dyes, often anionic or non-ionic, bind differently depending on fiber type, typically used on natural fibers like cotton or wool, which affects dye uptake and colorfastness. Your choice between cationic and regular dyes impacts the durability, brightness, and suitability of textiles for specific uses.

What Are Cationic Dyes?

Cationic dyes are positively charged dyes that bind effectively to negatively charged fibers such as acrylics and modified nylons, providing vibrant and long-lasting color. Unlike regular dyes, which may rely on physical absorption or chemical reactions, cationic dyes use ionic attraction to create a strong attachment to fabric fibers, resulting in superior colorfastness and intensity. Your choice of dye can significantly impact the durability and brilliance of the fabric's color, especially in synthetic materials.

Understanding Regular Dyes

Regular dyes, also known as direct or anionic dyes, possess negatively charged molecules that bind primarily to fibers through ionic interactions with positively charged sites on the fabric. These dyes are water-soluble and commonly used on cotton, rayon, and other cellulose fibers due to their ease of application and absorption. Compared to cationic dyes, regular dyes generally exhibit lower wash fastness and brightness because their fixation depends heavily on fiber composition and dyeing conditions.

Chemical Structure Comparison

Cationic dyes possess positively charged ions in their chemical structure, enabling strong electrostatic attraction to negatively charged substrates like wool, silk, and nylon, resulting in vibrant and wash-fast colors. Regular dyes, including acid, direct, and reactive dyes, generally lack this cationic charge and rely on different chemical interactions such as hydrogen bonding or covalent bonding with fiber molecules. The presence of quaternary ammonium groups in cationic dyes is a key structural difference that enhances dye affinity and fastness compared to the more diverse and often less charged structures found in regular dyes.

Application Processes: Cationic vs Regular

Cationic dyes exhibit superior affinity for synthetic fibers like acrylic, enabling direct application in low-temperature exhaust dyeing and continuous pad-dry methods, resulting in vibrant, wash-fast colors. Regular dyes, or anionic dyes, primarily apply to natural fibers such as cotton using high-temperature processes like jet or high-pressure dyeing with auxiliary chemicals to enhance fixation. The application efficiency of cationic dyes reduces energy consumption and processing time compared to regular dyes, which often require additional mordants and longer fixation cycles.

Colorfastness and Durability Differences

Cationic dyes exhibit superior colorfastness due to their strong ionic bonding with fabric fibers, resulting in colors that resist fading from washing, light, and perspiration. Regular dyes, often relying on weaker physical adsorption, tend to fade more quickly and show reduced durability under repeated laundering and environmental exposure. The enhanced durability of cationic dyes makes them ideal for textiles requiring long-lasting vibrant colors and resistance to harsh conditions.

Fiber Compatibility: Best Matches for Each Dye

Cationic dyes exhibit superior compatibility with synthetic fibers such as acrylic and polyester, offering vibrant color fastness and uniform penetration. Regular dyes, including direct and reactive dyes, are best matched with natural fibers like cotton, wool, and silk, ensuring strong chemical bonding and durability. Selecting the appropriate dye based on fiber composition enhances coloration quality and processing efficiency in textile manufacturing.

Environmental Impact and Safety

Cationic dyes exhibit lower environmental impact due to their superior substantivity, which reduces dye runoff and minimizes water pollution in textile wastewater. Regular dyes often require higher volumes and more toxic auxiliary chemicals, leading to increased chemical oxygen demand (COD) and ecological toxicity. Using cationic dyes enhances workplace safety as they generally contain fewer hazardous substances, lowering risks of skin irritation and respiratory issues for workers.

Cost Analysis: Cationic Dye vs Regular Dye

Cationic dyes typically incur higher upfront costs due to their complex synthesis and specialized application processes compared to regular dyes, which are often produced at larger scales with more standardized methods. However, cationic dyes offer superior fixation rates and reduced dye usage, resulting in lower overall consumption and less environmental impact, which can translate into cost savings in wastewater treatment and material waste. In large-scale textile manufacturing, the higher efficiency and improved fastness properties of cationic dyes may offset initial expenses, making them economically competitive against traditional dyeing methods.

Choosing the Right Dye for Your Project

Cationic dyes offer superior affinity for synthetic fibers like nylon and acrylic, providing vibrant, long-lasting colors that resist fading and washing out, making them ideal for projects requiring durability and brightness. Regular dyes, often acid or reactive dyes, work best on natural fibers such as cotton, wool, and silk, offering a wide range of shades but may require specific fiber types for optimal results. Understanding your fabric type and the desired colorfastness will guide you in choosing the right dye to ensure your project achieves its intended aesthetic and performance.

Cationic Dye vs Regular Dye Infographic

libmatt.com

libmatt.com