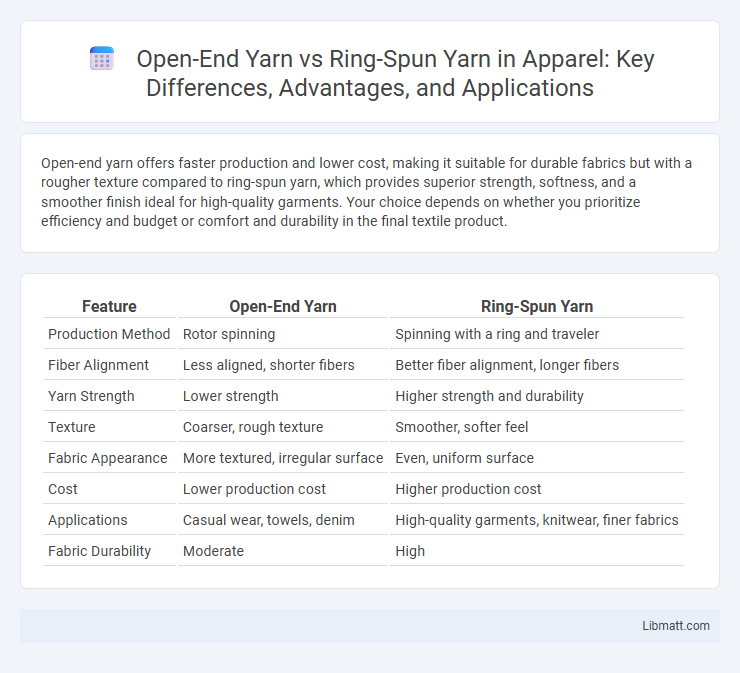

Open-end yarn offers faster production and lower cost, making it suitable for durable fabrics but with a rougher texture compared to ring-spun yarn, which provides superior strength, softness, and a smoother finish ideal for high-quality garments. Your choice depends on whether you prioritize efficiency and budget or comfort and durability in the final textile product.

Table of Comparison

| Feature | Open-End Yarn | Ring-Spun Yarn |

|---|---|---|

| Production Method | Rotor spinning | Spinning with a ring and traveler |

| Fiber Alignment | Less aligned, shorter fibers | Better fiber alignment, longer fibers |

| Yarn Strength | Lower strength | Higher strength and durability |

| Texture | Coarser, rough texture | Smoother, softer feel |

| Fabric Appearance | More textured, irregular surface | Even, uniform surface |

| Cost | Lower production cost | Higher production cost |

| Applications | Casual wear, towels, denim | High-quality garments, knitwear, finer fabrics |

| Fabric Durability | Moderate | High |

Introduction to Open-End and Ring-Spun Yarns

Open-end yarn is produced using a rotor spinning technique that allows faster manufacturing and results in coarser, more irregular fibers ideal for denim and casual fabrics. Ring-spun yarn, created through a traditional ring spinning process, features finer, stronger, and smoother fibers, making it suitable for high-quality garments and soft textiles. Understanding these differences helps you choose the right yarn type for durability, texture, and fabric performance.

Defining Open-End Yarn: Key Features

Open-end yarn, also known as rotor-spun yarn, is produced by feeding fibers into a rotating drum where they are twisted together without using a spindle, resulting in a faster and more cost-effective manufacturing process. Key features of open-end yarn include its coarser texture, lower tensile strength, and bulkier, more irregular appearance compared to ring-spun yarn, which is smoother and stronger due to its traditional spindle twisting method. Your choice between open-end and ring-spun yarn should consider these differences based on the desired fabric durability and feel.

What is Ring-Spun Yarn? Core Characteristics

Ring-spun yarn is produced by continuously twisting and thinning cotton fibers to create a strong, fine, and smooth thread ideal for high-quality textiles. Its core characteristics include superior durability, softness, and a tighter, more consistent twist compared to open-end yarn, resulting in enhanced fabric strength and comfort. You'll find ring-spun yarn commonly used in premium apparel where longevity and a refined texture are essential.

Manufacturing Process: Open-End vs Ring-Spun

Open-end yarn is produced by inserting fibers into a rotor, where they are spun together rapidly, allowing for faster and more automated manufacturing with less labor intensity. Ring-spun yarn involves drawing out and twisting fibers on a spindle, creating a finer, stronger yarn with a more traditional and slower, labor-intensive process. Your choice between these yarn types depends on balancing production speed and fabric quality requirements.

Fiber Types Compatible with Each Yarn

Open-end yarn is primarily compatible with short-staple fibers such as cotton, polyester, and recycled materials, making it suitable for mass-produced fabrics with less emphasis on softness. Ring-spun yarn, compatible with long-staple fibers like Egyptian cotton, Pima cotton, and other premium fibers, produces stronger and finer yarn with a smoother texture. You can choose ring-spun yarn for high-quality textiles requiring durability and comfort, while open-end yarn suits cost-effective, coarse fabric applications.

Strength and Durability Comparison

Open-end yarn exhibits lower tensile strength and reduced durability compared to ring-spun yarn due to its coarser fiber arrangement and shorter fiber length integration. Ring-spun yarn, crafted by twisting long fibers tightly, offers superior strength and enhanced wear resistance suitable for high-stress textile applications. The compact fiber structure in ring-spun yarn results in greater fabric longevity and less pilling, making it preferable for durable garments.

Texture and Feel: Yarn Surface Differences

Open-end yarn features a coarser, uneven texture due to its spinning process, resulting in a rougher surface that feels less smooth against the skin. Ring-spun yarn, spun by twisting fibers more tightly, creates a finer, smoother, and softer surface, offering enhanced comfort and durability. Your choice between these yarns affects fabric texture, with ring-spun ideal for garments requiring a soft touch and open-end suitable for more rugged textiles.

Cost and Production Efficiency

Open-end yarn production is generally more cost-effective due to its faster spinning speed and lower labor requirements, enabling higher output per hour compared to ring-spun yarn. Ring-spun yarn, while producing finer and stronger fibers, involves a more time-consuming and labor-intensive process, resulting in higher production costs. Your choice between the two depends on balancing the need for cost efficiency with desired yarn quality and fabric characteristics.

End-Use Applications: Where Each Yarn Excels

Open-end yarn excels in producing denim, towels, and upholstery fabrics due to its coarser texture and higher productivity. Ring-spun yarn offers superior strength and softness, making it ideal for high-quality garments like T-shirts, dress shirts, and fine knitwear. Your choice depends on the desired fabric durability and feel, with open-end suited for robust, heavy-duty textiles and ring-spun preferred for comfortable, premium apparel.

Sustainability Aspects of Both Yarns

Open-end yarn production consumes less energy and water compared to ring-spun yarn, making it more sustainable in resource use. Ring-spun yarn offers higher durability and longevity, which can contribute to less frequent garment replacement and reduced textile waste. Your choice between these yarns can impact overall environmental footprint, balancing resource efficiency and product lifespan.

Open-end yarn vs ring-spun yarn Infographic

libmatt.com

libmatt.com