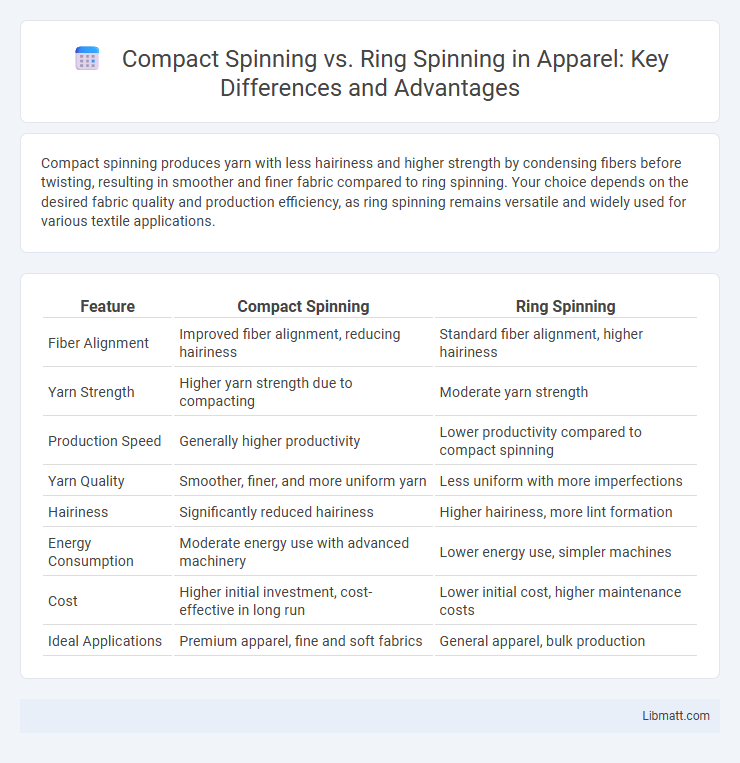

Compact spinning produces yarn with less hairiness and higher strength by condensing fibers before twisting, resulting in smoother and finer fabric compared to ring spinning. Your choice depends on the desired fabric quality and production efficiency, as ring spinning remains versatile and widely used for various textile applications.

Table of Comparison

| Feature | Compact Spinning | Ring Spinning |

|---|---|---|

| Fiber Alignment | Improved fiber alignment, reducing hairiness | Standard fiber alignment, higher hairiness |

| Yarn Strength | Higher yarn strength due to compacting | Moderate yarn strength |

| Production Speed | Generally higher productivity | Lower productivity compared to compact spinning |

| Yarn Quality | Smoother, finer, and more uniform yarn | Less uniform with more imperfections |

| Hairiness | Significantly reduced hairiness | Higher hairiness, more lint formation |

| Energy Consumption | Moderate energy use with advanced machinery | Lower energy use, simpler machines |

| Cost | Higher initial investment, cost-effective in long run | Lower initial cost, higher maintenance costs |

| Ideal Applications | Premium apparel, fine and soft fabrics | General apparel, bulk production |

Introduction to Compact Spinning and Ring Spinning

Compact spinning enhances traditional ring spinning by condensing fiber strands before twisting, resulting in stronger, smoother yarn with fewer hair fibers. Ring spinning remains the industry standard for producing high-quality yarn through the continuous twisting of fiber strands on a ring frame. Your textile manufacturing process can benefit from understanding the differences in fiber alignment, yarn strength, and production efficiency between these two methods.

Overview of Spinning Technologies

Compact spinning enhances traditional ring spinning by condensing the fiber strand, reducing hairiness and improving yarn strength and uniformity. Ring spinning remains the most widely used technology, known for its versatility and ability to produce fine, strong yarns, but it generates more waste fibers compared to compact spinning. Advances in compact spinning optimize fiber alignment and twist, resulting in higher-quality yarn suitable for premium textile applications.

Working Principle of Ring Spinning

Ring spinning operates by drafting fibers and twisting them with a rotating ring and traveler system, creating a strong and durable yarn. The spindle rotates at high speed, guiding the yarn through the traveler on the ring, which controls tension and twist insertion. Your choice of ring spinning ensures consistent yarn quality and is ideal for producing fine to medium count textiles.

Compact Spinning Technology Explained

Compact spinning technology enhances traditional ring spinning by condensing the fiber strand before twisting, resulting in improved yarn strength, uniformity, and reduced hairiness. This process uses a compacting zone where fibers are tightly gathered, minimizing fiber fly and imperfections compared to conventional ring spinning. The technology boosts productivity and yarn quality, making it ideal for fine and high-performance textiles.

Fiber Structure and Yarn Construction

Compact spinning produces yarn with a tighter fiber structure by condensing fibers before twist insertion, resulting in reduced hairiness and enhanced yarn strength compared to ring spinning. Ring spinning relies on a traditional draft and twist mechanism, leading to a looser fiber arrangement with more protruding fibers, which can increase yarn surface roughness. The compact spinning process improves yarn uniformity and smoothness by minimizing fiber fly and irregularities during yarn construction.

Yarn Quality: Strength, Uniformity, and Hairiness

Compact spinning produces yarn with superior strength, enhanced uniformity, and significantly reduced hairiness compared to ring spinning, resulting in smoother and more durable fabric. The compact process aligns fibers more tightly, minimizing fiber fly and imperfections, which directly contributes to improved yarn quality. Your textile products will benefit from increased durability and a cleaner appearance with compact spinning technology.

Production Efficiency and Cost Comparison

Compact spinning technology enhances production efficiency by reducing yarn hairiness and improving tensile strength, resulting in fewer breakages and higher machine speeds compared to traditional ring spinning. While initial investment costs for compact spinning systems are higher, the reduction in waste, improved yarn quality, and lower labor costs lead to long-term savings and a more cost-effective production process. Your choice between compact and ring spinning should consider these factors to optimize both output and overall operational expenses.

Applications in the Textile Industry

Compact spinning produces yarns with higher tensile strength and reduced hairiness, making it ideal for fine and high-quality fabrics used in the apparel and home textiles sectors. Ring spinning remains dominant for versatile yarn production, suitable for denim, knitwear, and industrial textiles due to its balance of strength and softness. Textile manufacturers choose compact spinning for premium products requiring superior fabric appearance and durability, while ring spinning is preferred for mass production and diverse fabric types.

Environmental Impact and Sustainability

Compact spinning reduces fiber waste and energy consumption compared to ring spinning, leading to lower greenhouse gas emissions during production. The improved yarn quality from compact spinning also results in less fabric defect rates and reduced resource usage in downstream processing. Sustainable textile manufacturing benefits from compact spinning's efficiency and minimized environmental footprint, supporting eco-friendly practices in the industry.

Key Differences and Future Trends

Compact spinning produces yarn with higher strength and less hairiness by condensing the fiber strand, whereas ring spinning offers versatility and cost-effectiveness with its well-established technology. Advances in compact spinning technology aim to enhance production speed and energy efficiency, positioning it as a preferred choice for high-quality yarn applications. Incorporating compact spinning into your textile manufacturing can lead to superior fabric performance and reduced waste, aligning with future industry trends toward sustainability and innovation.

compact spinning vs ring spinning Infographic

libmatt.com

libmatt.com