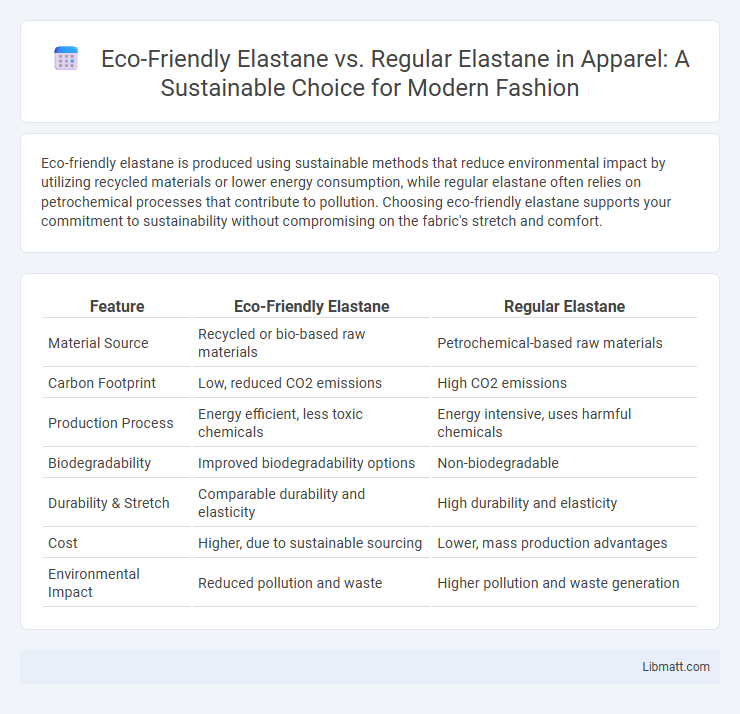

Eco-friendly elastane is produced using sustainable methods that reduce environmental impact by utilizing recycled materials or lower energy consumption, while regular elastane often relies on petrochemical processes that contribute to pollution. Choosing eco-friendly elastane supports your commitment to sustainability without compromising on the fabric's stretch and comfort.

Table of Comparison

| Feature | Eco-Friendly Elastane | Regular Elastane |

|---|---|---|

| Material Source | Recycled or bio-based raw materials | Petrochemical-based raw materials |

| Carbon Footprint | Low, reduced CO2 emissions | High CO2 emissions |

| Production Process | Energy efficient, less toxic chemicals | Energy intensive, uses harmful chemicals |

| Biodegradability | Improved biodegradability options | Non-biodegradable |

| Durability & Stretch | Comparable durability and elasticity | High durability and elasticity |

| Cost | Higher, due to sustainable sourcing | Lower, mass production advantages |

| Environmental Impact | Reduced pollution and waste | Higher pollution and waste generation |

Introduction to Elastane: Definition and Uses

Elastane, a synthetic fiber known for exceptional elasticity, is widely used in textiles for garments requiring stretchability, such as activewear, swimwear, and lingerie. Eco-friendly elastane is produced with sustainable processes, lower emissions, and recycled materials, reducing environmental impact compared to regular elastane. While both types maintain high durability and stretch properties, eco-friendly elastane addresses growing consumer demand for sustainable fashion choices.

What is Regular Elastane?

Regular elastane, a synthetic fiber known for its exceptional elasticity, is widely used in clothing to provide stretch and comfort. It is derived from petrochemical sources, contributing to environmental concerns due to its non-biodegradable nature and energy-intensive production process. Choosing eco-friendly elastane alternatives reduces your carbon footprint by incorporating recycled materials or sustainable manufacturing methods that minimize environmental impact.

The Rise of Eco-Friendly Elastane

Eco-friendly elastane is gaining traction due to its sustainable production methods, reducing environmental impact compared to regular elastane derived from non-renewable fossil fuels. Utilizing recycled or bio-based materials, eco-friendly elastane minimizes carbon emissions and water usage while maintaining high stretch and durability. Your choice to support eco-friendly elastane promotes a greener textile industry and helps decrease pollution in fashion manufacturing.

Key Differences: Eco-Friendly vs Regular Elastane

Eco-friendly elastane is produced using sustainable practices, incorporating recycled materials and non-toxic solvents, which reduces environmental impact compared to regular elastane made from petrochemical sources with higher emissions. This sustainable variant often features biodegradability or improved recyclability, supporting circular economy goals absent in conventional elastane production. Performance characteristics such as elasticity and durability remain comparable, though eco-friendly elastane may offer enhanced chemical safety and lower carbon footprint metrics.

Environmental Impact of Traditional Elastane

Traditional elastane production heavily relies on petroleum-based raw materials, resulting in significant carbon emissions and non-biodegradable waste contributing to environmental pollution. Its manufacturing process consumes high amounts of energy and releases harmful chemicals that affect air and water quality. Choosing eco-friendly elastane reduces your ecological footprint by utilizing sustainable sources and cleaner production methods with lower toxicity.

Sustainable Production Practices in Elastane Manufacturing

Eco-friendly elastane is produced using sustainable production practices such as reduced water consumption, lower greenhouse gas emissions, and the incorporation of bio-based raw materials. These practices minimize environmental impact by utilizing renewable inputs like plant-derived polymers and implementing energy-efficient manufacturing processes. In contrast, regular elastane manufacturing often relies heavily on fossil fuels and generates significant chemical waste and pollution.

Benefits of Eco-Friendly Elastane for Fashion Brands

Eco-friendly elastane offers fashion brands a sustainable alternative by reducing environmental impact through lower carbon emissions and decreased water usage during production. This material enhances brand reputation by aligning with growing consumer demand for sustainable and ethically produced apparel. Incorporating eco-friendly elastane supports circular fashion initiatives, promoting recyclability and reducing textile waste in supply chains.

Performance Comparison: Eco-Friendly vs Conventional Elastane

Eco-friendly elastane delivers comparable stretch, durability, and moisture-wicking properties to conventional elastane while reducing environmental impact through sustainable sourcing and production methods. Performance metrics such as elasticity retention after multiple washes and resistance to wear demonstrate that eco-friendly elastane maintains garment integrity without compromising comfort or fit. Your choice of eco-friendly elastane supports eco-conscious apparel manufacturing without sacrificing the high-performance standards expected in activewear and fashion.

Challenges and Limitations of Eco-Friendly Elastane

Eco-friendly elastane faces challenges such as higher production costs and limited scalability compared to regular elastane, which restricts widespread adoption. The recycling process for eco-friendly elastane often demands specialized facilities that are not yet globally accessible. Performance can also be inconsistent, with some eco-friendly variants lacking the stretch and durability of conventional elastane.

Future Trends in Sustainable Elastane Development

Future trends in sustainable elastane development emphasize bio-based raw materials and closed-loop recycling technologies that drastically reduce carbon footprints and water usage. Innovations include the utilization of plant-derived polymers and enzymatic processes to break down elastane fibers for reuse, enhancing circularity in textile manufacturing. Collaboration between fiber producers and fashion brands accelerates adoption of eco-friendly elastane, meeting growing consumer demand for sustainable performance fabrics.

eco-friendly elastane vs regular elastane Infographic

libmatt.com

libmatt.com