Seam strength improves as stitch density increases, providing a more secure and durable bond between fabric layers. Your choice of optimal stitch density balances durability with fabric flexibility to prevent seam failure and maintain garment comfort.

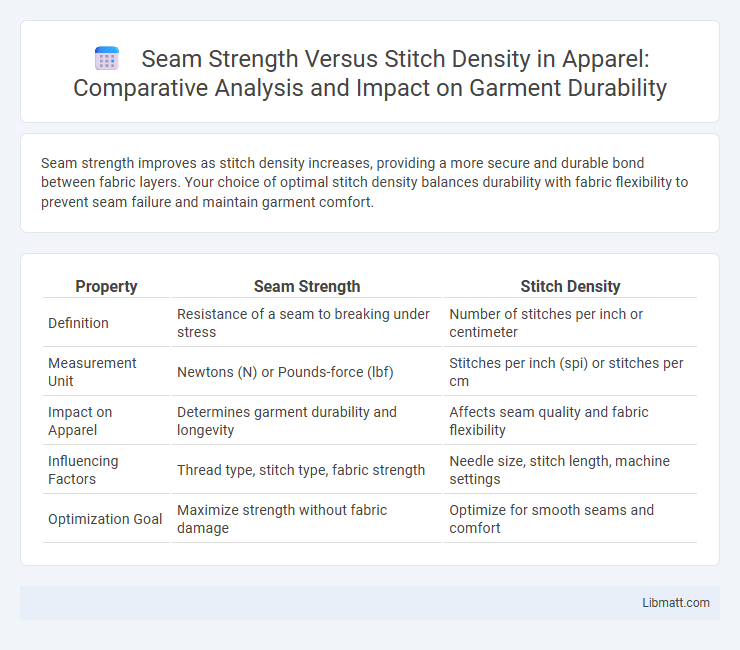

Table of Comparison

| Property | Seam Strength | Stitch Density |

|---|---|---|

| Definition | Resistance of a seam to breaking under stress | Number of stitches per inch or centimeter |

| Measurement Unit | Newtons (N) or Pounds-force (lbf) | Stitches per inch (spi) or stitches per cm |

| Impact on Apparel | Determines garment durability and longevity | Affects seam quality and fabric flexibility |

| Influencing Factors | Thread type, stitch type, fabric strength | Needle size, stitch length, machine settings |

| Optimization Goal | Maximize strength without fabric damage | Optimize for smooth seams and comfort |

Introduction to Seam Strength and Stitch Density

Seam strength measures the resistance of a seam to forces that try to pull it apart, influenced by factors such as thread type, stitch pattern, and fabric. Stitch density, defined as the number of stitches per inch, directly affects the durability and performance of the seam by distributing stress more evenly or increasing fabric perforation. Understanding the balance between seam strength and stitch density is essential for optimizing garment durability and maintaining fabric integrity.

Defining Seam Strength in Textile Engineering

Seam strength in textile engineering measures the maximum force a seam can withstand before failure, ensuring garment durability and performance under stress. It depends on factors like fiber type, seam construction, and stitch density, where higher stitch density generally increases seam integrity by distributing load more evenly. Accurate testing of seam strength involves assessing tensile forces and evaluating failure modes to optimize fabric and seam design for specific applications.

What is Stitch Density?

Stitch density refers to the number of stitches per inch in a sewn seam, directly impacting the seam's durability and flexibility. Higher stitch density provides greater seam strength by distributing stress evenly and reducing fabric distortion under tension. Optimal stitch density balances material type and garment function to enhance both performance and longevity.

Importance of Seam Strength in Garment Durability

Seam strength directly impacts the durability and longevity of garments, ensuring they withstand stress and wear during regular use. Higher stitch density typically increases seam strength by distributing tension more evenly across the fabric, reducing the risk of threads breaking or seams unraveling. Your clothing's performance and lifespan significantly benefit from optimized seam strength through proper stitch density, enhancing overall quality and reliability.

Role of Stitch Density in Fabric Performance

Higher stitch density significantly improves seam strength by distributing stress more evenly across the fabric, reducing the likelihood of seam failure. Increased stitch density enhances fabric performance by providing better resistance to tearing and abrasion, which preserves the integrity of sewn materials under tension. Your choice of stitch density directly impacts the durability and reliability of seams in various textile applications.

Factors Affecting Seam Strength

Seam strength is significantly influenced by stitch density, which determines the number of stitches per inch and directly affects the overall durability of the seam. Factors affecting seam strength include fabric type, thread quality, stitch length, and tension, all of which interact with stitch density to optimize the seam's resistance to stress and wear. Understanding these variables helps you achieve the ideal balance for durable, high-quality seams in textile products.

How Stitch Density Influences Seam Integrity

Higher stitch density directly enhances seam integrity by distributing tension uniformly across the fabric, reducing the likelihood of thread breakage and fabric distortion. Optimal stitch density minimizes seam gaps and reinforces the connection between fabric layers, contributing to improved durability and resistance to wear. Excessively high stitch density, however, can cause fabric puckering or weakening of fibers, so balance is crucial for maintaining seam strength and overall garment performance.

Comparative Analysis: Seam Strength vs Stitch Density

Seam strength directly correlates with stitch density, where higher stitch density typically enhances the seam's durability and resistance to stress. Optimal stitch density balances fabric integrity and seam performance, preventing material damage while maximizing tensile strength. Understanding this relationship is crucial for tailoring your sewing parameters to achieve durable seams in various textile applications.

Optimizing Stitch Density for Maximum Seam Strength

Optimizing stitch density is crucial for achieving maximum seam strength without compromising fabric integrity. Higher stitch density increases seam durability by distributing stress evenly across the seam, but excessive density can cause fabric distortion or thread breakage. Your choice of stitch density should balance tensile strength requirements with fabric type to ensure long-lasting, resilient seams in various applications.

Conclusion: Balancing Seam Strength and Stitch Density

Balancing seam strength and stitch density is essential for durable and reliable fabric construction. Higher stitch density generally increases seam strength by distributing stress evenly, but excessive density can cause fabric pucker and reduce flexibility. Optimal stitch density depends on fabric type and intended use, ensuring maximum seam integrity without compromising material performance.

Seam Strength vs Stitch Density Infographic

libmatt.com

libmatt.com