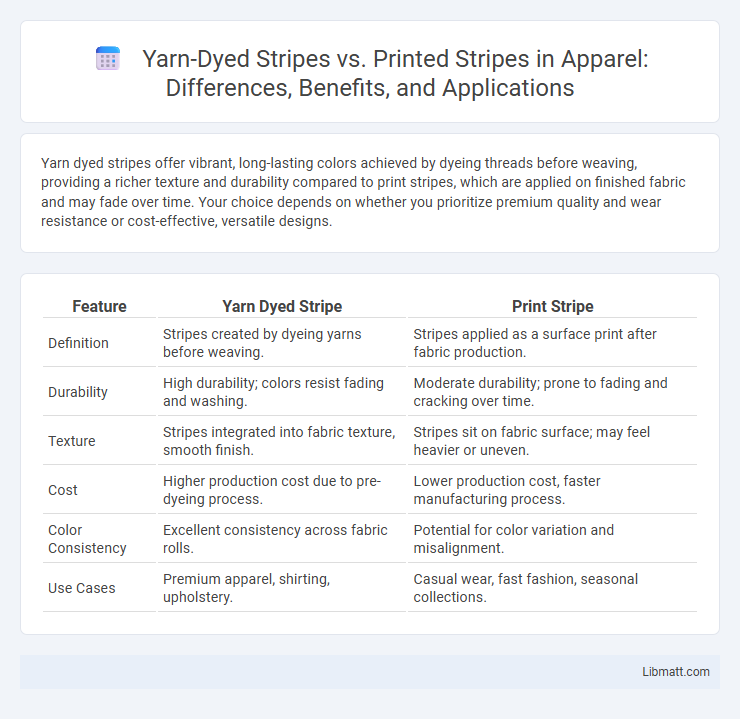

Yarn dyed stripes offer vibrant, long-lasting colors achieved by dyeing threads before weaving, providing a richer texture and durability compared to print stripes, which are applied on finished fabric and may fade over time. Your choice depends on whether you prioritize premium quality and wear resistance or cost-effective, versatile designs.

Table of Comparison

| Feature | Yarn Dyed Stripe | Print Stripe |

|---|---|---|

| Definition | Stripes created by dyeing yarns before weaving. | Stripes applied as a surface print after fabric production. |

| Durability | High durability; colors resist fading and washing. | Moderate durability; prone to fading and cracking over time. |

| Texture | Stripes integrated into fabric texture, smooth finish. | Stripes sit on fabric surface; may feel heavier or uneven. |

| Cost | Higher production cost due to pre-dyeing process. | Lower production cost, faster manufacturing process. |

| Color Consistency | Excellent consistency across fabric rolls. | Potential for color variation and misalignment. |

| Use Cases | Premium apparel, shirting, upholstery. | Casual wear, fast fashion, seasonal collections. |

Introduction to Yarn Dyed Stripes and Print Stripes

Yarn dyed stripes are created by dyeing individual threads before weaving, resulting in vibrant, long-lasting colors with excellent colorfastness and a textured appearance. Print stripes are applied to the fabric surface after weaving, offering more design flexibility but less durability and a flatter finish. Understanding the differences helps you choose the right stripe style for your fashion or interior projects based on quality and visual impact.

What Are Yarn Dyed Stripes?

Yarn dyed stripes are created by dyeing the yarns before they are woven into fabric, resulting in vivid, durable patterns with color fastness and improved texture quality. This method ensures the stripes are integral to the fabric's structure, offering superior resistance to fading and wear compared to print stripes, which are applied post-weaving. Yarn dyed stripes are commonly used in high-end textiles for apparel, upholstery, and home decor due to their enhanced appearance and longevity.

What Are Print Stripes?

Print stripes are patterns applied to fabric surfaces using printing techniques such as screen printing or digital printing, offering vibrant colors and intricate designs without altering the fabric's base structure. Unlike yarn dyed stripes, which are created by weaving colored threads into the fabric, print stripes allow more precise designs and quicker production with reduced material costs. Your choice between print and yarn dyed stripes depends on the desired texture, durability, and visual effects for your textile projects.

Manufacturing Process: Yarn Dyed vs Print Stripe

Yarn dyed stripes involve weaving or knitting fabric with pre-dyed yarns, resulting in patterns embedded in the fabric's structure, enhancing durability and colorfastness. Print stripe fabrics are produced by applying dyes or pigments to the surface of already woven or knitted fabric, allowing for more intricate designs but with potentially less color longevity. The manufacturing process of yarn dyed stripe requires more time and precision to align colors in yarns, while print stripe offers greater flexibility and faster production for varied stripe patterns.

Visual Appearance and Texture Differences

Yarn dyed stripes exhibit a richer visual appearance with vibrant, well-defined colors due to the individual threads being dyed before weaving, creating a textured, durable fabric with distinct color patterns. Print stripes, on the other hand, feature a smoother surface where the stripe design is applied post-weaving, often resulting in less depth and a flatter texture. The yarn dyeing process enhances fabric longevity and colorfastness, while printed stripes may fade more quickly and lack the intricate texture found in yarn dyed materials.

Durability and Colorfastness Comparison

Yarn dyed stripes offer superior durability and colorfastness compared to print stripes due to the color being woven directly into the fabric, ensuring long-lasting vibrancy even after repeated washing. Print stripes tend to fade faster over time since the color is applied on the fabric surface and may wear off with abrasion or laundering. Choosing yarn dyed stripes for your textiles guarantees enhanced resistance to fading and a more consistent appearance throughout the fabric's lifespan.

Cost Implications and Economic Considerations

Yarn dyed stripe fabrics generally involve higher production costs due to the complex process of dyeing the yarn before weaving, which requires more time, labor, and specialized equipment. Print stripe fabrics offer a cost-effective alternative with lower manufacturing expenses since the stripes are applied after the fabric is woven, reducing dye consumption and production time. Businesses must weigh the initial investment and long-term durability benefits of yarn dyed stripes against the affordability and faster turnaround of print stripe options when making economic decisions.

Applications in Fashion and Interiors

Yarn dyed stripes, created by weaving pre-dyed threads, offer superior colorfastness and texture, making them ideal for high-end fashion garments and durable interior upholstery where longevity and elegance are essential. Print stripes apply color directly onto the fabric surface, allowing for intricate, custom patterns suitable for trendy apparel and decorative home accents like curtains and cushions. Your choice between yarn dyed and print stripes depends on the desired durability, aesthetic complexity, and application environment in both fashion and interior design.

Sustainability and Environmental Impact

Yarn dyed stripe fabrics are more sustainable due to their production process, which involves dyeing the fibers before weaving, reducing the use of water and chemicals compared to print stripe fabrics that require additional dyeing and finishing steps. The longevity of yarn dyed stripes enhances environmental benefits by minimizing textile waste and the need for frequent replacement. In contrast, print stripe fabrics often involve synthetically derived inks and higher energy consumption during printing, contributing to a larger carbon footprint.

Choosing the Right Stripe for Your Project

Yarn dyed stripe fabrics offer durability and vibrant colors as the pattern is woven into the fabric, making them ideal for high-quality projects requiring long-lasting design integrity. Print stripe fabrics provide more flexibility with intricate or custom stripe patterns and are often more cost-effective for short-run or seasonal items. You should consider the project's budget, desired texture, and intended use to choose between yarn dyed and print stripe fabrics for optimal results.

Yarn Dyed Stripe vs Print Stripe Infographic

libmatt.com

libmatt.com