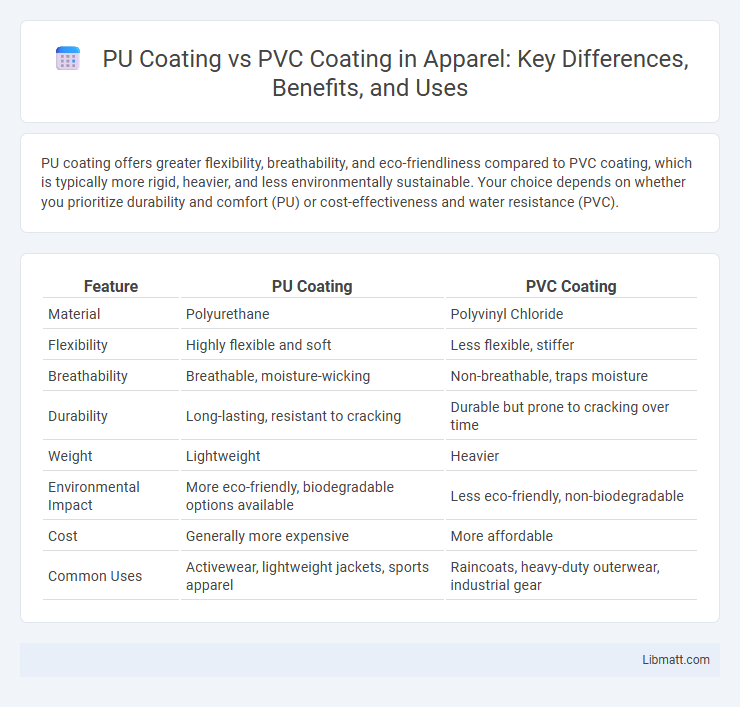

PU coating offers greater flexibility, breathability, and eco-friendliness compared to PVC coating, which is typically more rigid, heavier, and less environmentally sustainable. Your choice depends on whether you prioritize durability and comfort (PU) or cost-effectiveness and water resistance (PVC).

Table of Comparison

| Feature | PU Coating | PVC Coating |

|---|---|---|

| Material | Polyurethane | Polyvinyl Chloride |

| Flexibility | Highly flexible and soft | Less flexible, stiffer |

| Breathability | Breathable, moisture-wicking | Non-breathable, traps moisture |

| Durability | Long-lasting, resistant to cracking | Durable but prone to cracking over time |

| Weight | Lightweight | Heavier |

| Environmental Impact | More eco-friendly, biodegradable options available | Less eco-friendly, non-biodegradable |

| Cost | Generally more expensive | More affordable |

| Common Uses | Activewear, lightweight jackets, sports apparel | Raincoats, heavy-duty outerwear, industrial gear |

Introduction to PU and PVC Coatings

PU coating, or polyurethane coating, is a versatile, durable layer known for its flexibility, abrasion resistance, and excellent chemical resistance, making it ideal for textiles, leather, and automotive industries. PVC coating, or polyvinyl chloride coating, offers strong waterproofing, high durability, and cost-effectiveness, commonly used in rainwear, tarpaulins, and inflatable products. Your choice between PU and PVC coatings depends on the specific application requirements such as breathability, environmental impact, and mechanical properties.

Chemical Structure and Composition

PU coating consists of polyurethane polymers, which have urethane linkages formed by the reaction of polyols and isocyanates, offering greater flexibility and durability due to their segmented block copolymer structure. PVC coating is composed of polyvinyl chloride resin combined with plasticizers, stabilizers, and fillers, creating a rigid and less breathable material with a chlorinated backbone. The chemical composition of PU allows for better abrasion resistance and elasticity, whereas PVC's vinyl chloride units provide higher resistance to chemicals and flame retardancy but at the cost of reduced environmental friendliness and flexibility.

Manufacturing Processes

PU coating involves applying a polyurethane layer through either hot lamination or solvent-based methods, resulting in a flexible, breathable finish ideal for apparel and upholstery. PVC coating is produced by mixing polyvinyl chloride with plasticizers and additives, then spreading or calendering the mixture onto fabric, offering robust waterproofing and durability suited for industrial and outdoor applications. PU coatings typically require cleaner, more precise manufacturing environments, while PVC processes are more cost-effective but involve higher environmental considerations due to chlorine content.

Durability and Longevity Comparison

PU coating offers superior durability and flexibility compared to PVC coating, making it more resistant to cracking and abrasions over time. Its enhanced longevity is attributed to better resistance against UV exposure, chemicals, and extreme temperatures. PVC coating, while cost-effective, tends to become brittle and degrade faster under harsh environmental conditions.

Waterproofing Capabilities

PU coating offers superior waterproofing capabilities compared to PVC coating due to its higher resistance to water penetration and increased breathability, allowing moisture vapor to escape while blocking liquid water. PVC coating provides effective waterproofing but tends to be less breathable, which can lead to condensation buildup and reduced comfort in applications like outdoor gear or clothing. The enhanced flexibility and durability of PU coatings contribute to long-lasting waterproof performance, especially under varying environmental conditions.

Breathability and Comfort

PU coating offers superior breathability compared to PVC coating, allowing moisture vapor to escape and enhancing overall comfort during wear. This permeability helps regulate body temperature, reducing sweat buildup and skin irritation. Your garments with PU coating will feel lighter and more comfortable, especially in active or warm conditions.

Environmental Impact

PU coating offers a lower environmental impact compared to PVC coating due to its biodegradable properties and the absence of harmful chlorine compounds. PVC coatings release toxic dioxins and require additives like plasticizers, which contribute to pollution and pose health risks. PU coatings also consume less energy during production, making them a more sustainable choice for eco-conscious applications.

Cost Analysis

PU coating generally offers a higher upfront cost compared to PVC coating due to its advanced material properties and enhanced durability. However, Your long-term expenses may be lower with PU coating as it provides better resistance to abrasion and environmental factors, reducing maintenance and replacement frequency. PVC coating remains a budget-friendly choice for applications requiring cost-effectiveness over extended performance.

Common Applications and Industries

PU coating is widely used in industries requiring flexible, durable, and breathable materials, such as sportswear, automotive interiors, and medical textiles. PVC coating is commonly applied in heavy-duty sectors like outdoor gear, tarpaulins, and industrial protective clothing due to its waterproof and chemical-resistant properties. Your choice between PU and PVC coatings should align with the specific application needs regarding flexibility, durability, and environmental exposure.

Choosing Between PU and PVC Coatings

Choosing between PU and PVC coatings depends on your specific needs for durability and flexibility. PU coatings offer superior abrasion resistance and breathability, making them ideal for high-performance applications such as sportswear and outdoor gear. PVC coatings excel in waterproofing and chemical resistance, often used for industrial tarps and protective covers where toughness and longevity are crucial.

PU coating vs PVC coating Infographic

libmatt.com

libmatt.com