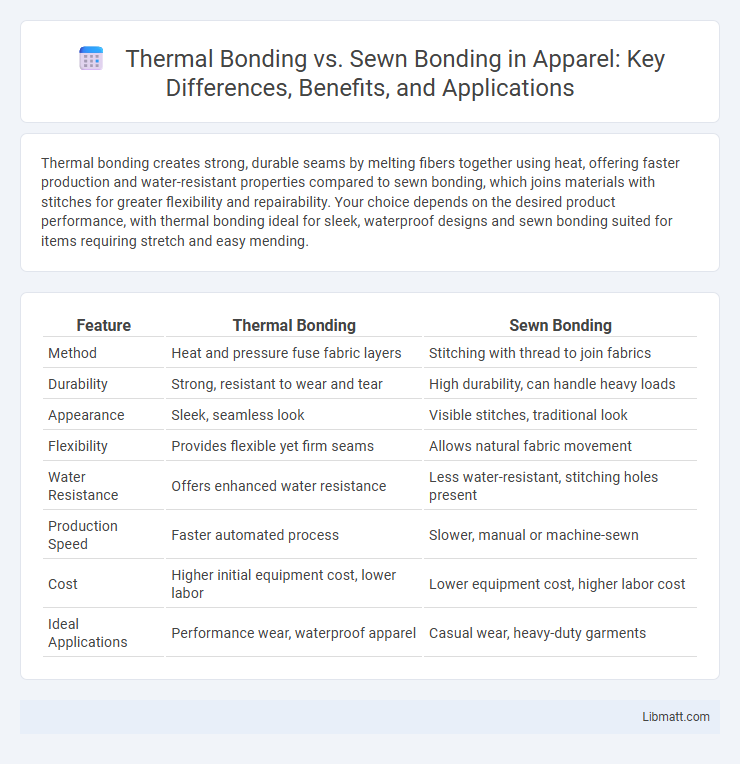

Thermal bonding creates strong, durable seams by melting fibers together using heat, offering faster production and water-resistant properties compared to sewn bonding, which joins materials with stitches for greater flexibility and repairability. Your choice depends on the desired product performance, with thermal bonding ideal for sleek, waterproof designs and sewn bonding suited for items requiring stretch and easy mending.

Table of Comparison

| Feature | Thermal Bonding | Sewn Bonding |

|---|---|---|

| Method | Heat and pressure fuse fabric layers | Stitching with thread to join fabrics |

| Durability | Strong, resistant to wear and tear | High durability, can handle heavy loads |

| Appearance | Sleek, seamless look | Visible stitches, traditional look |

| Flexibility | Provides flexible yet firm seams | Allows natural fabric movement |

| Water Resistance | Offers enhanced water resistance | Less water-resistant, stitching holes present |

| Production Speed | Faster automated process | Slower, manual or machine-sewn |

| Cost | Higher initial equipment cost, lower labor | Lower equipment cost, higher labor cost |

| Ideal Applications | Performance wear, waterproof apparel | Casual wear, heavy-duty garments |

Introduction to Bonding Techniques

Thermal bonding uses heat and pressure to fuse materials without adhesives or stitching, resulting in strong, seamless joins ideal for technical textiles and filtration products. Sewn bonding involves stitching materials together with thread, offering flexibility and durability suited for garments and upholstery. Your choice between thermal and sewn bonding depends on the application requirements such as strength, flexibility, and aesthetic finish.

What is Thermal Bonding?

Thermal bonding is a manufacturing process that uses heat and pressure to fuse materials together without stitches, creating strong, seamless bonds ideal for fabrics like nonwovens and technical textiles. This technique enhances durability and water resistance while maintaining flexibility and breathability in the finished product. Understanding thermal bonding helps you choose efficient, high-performance materials for applications ranging from medical supplies to automotive interiors.

What is Sewn Bonding?

Sewn bonding is a fabric joining technique that uses stitches to interlock fabric layers, providing strength and flexibility in textile construction. This method is widely used in apparel, upholstery, and industrial fabrics where durability and tailored shape retention are critical. Your choice between sewn bonding and thermal bonding depends on factors like fabric type, desired aesthetics, and performance requirements.

Material Compatibility in Bonding Methods

Thermal bonding excels with thermoplastic materials that soften under heat, creating strong, uniform bonds without adhesives or threads, ideal for polyester, polyurethane, and polypropylene fabrics. Sewn bonding offers versatile compatibility across a wider range of materials, including natural fibers like cotton and blends, allowing mechanical stitching to securely join layers regardless of thermal properties. Material compatibility in bonding methods determines the choice: thermal bonding suits heat-sensitive thermoplastics, while sewn bonding adapts better to mixed or heat-sensitive textiles.

Strength and Durability Comparison

Thermal bonding creates a strong, uniform bond by melting and fusing materials at a molecular level, resulting in enhanced durability and resistance to wear. Sewn bonding relies on stitching, which can introduce weak points and is susceptible to unraveling under stress or repeated use. Your choice of bonding method directly affects the longevity and strength of the finished product, with thermal bonding generally providing superior performance for high-stress applications.

Flexibility and Comfort of Bonded Products

Thermal bonding creates flexible, smooth seams by fusing materials with heat, enhancing the comfort of wearable products by eliminating bulky stitches and reducing skin irritation. Sewn bonding provides durability and strength but may compromise flexibility due to raised seams and threads that can cause discomfort during prolonged use. Your choice between thermal and sewn bonding impacts the overall comfort and flexibility of the final product, especially in applications like activewear or medical garments.

Production Efficiency and Cost Analysis

Thermal bonding offers higher production efficiency due to faster processing speeds and reduced labor requirements compared to sewn bonding, which relies on manual stitching and longer assembly times. Cost analysis reveals thermal bonding significantly lowers manufacturing expenses by eliminating thread costs and minimizing machine maintenance, whereas sewn bonding incurs ongoing costs for needles, threads, and skilled labor. The investment in thermal bonding technology is offset by scalable production throughput and reduced material waste, driving overall cost-effectiveness in large-scale manufacturing.

Common Applications for Each Bonding Method

Thermal bonding is commonly utilized in the production of nonwoven fabrics for hygiene products, medical gowns, and filtration materials due to its ability to create strong, uniform bonds without the use of adhesives or stitching. Sewn bonding, often applied in upholstery, automotive interiors, and outdoor gear, allows for greater flexibility and durability where precise seam strength and aesthetic detail are essential. Your choice between these methods depends on the desired strength, appearance, and application requirements of the final product.

Sustainability and Environmental Impact

Thermal bonding offers a more sustainable alternative to sewn bonding by eliminating the need for additional materials like thread, reducing waste generated during production. This process consumes less energy and water compared to sewing, lowering the overall environmental footprint in textile manufacturing. Moreover, thermal bonding facilitates the use of recyclable and biodegradable materials, enhancing eco-friendly product lifecycle management.

Choosing the Right Bonding Technique

Choosing the right bonding technique depends on the material properties and the desired durability; thermal bonding uses heat and pressure to fuse fabrics without thread, offering a smooth finish ideal for synthetic textiles and waterproof applications. Sewn bonding involves stitching fabrics together, providing superior strength and flexibility for heavy-duty or high-stress garments. Evaluating factors such as cost, production speed, and end-use performance is crucial to determine whether thermal bonding or sewn bonding best meets specific product requirements.

Thermal Bonding vs Sewn Bonding Infographic

libmatt.com

libmatt.com