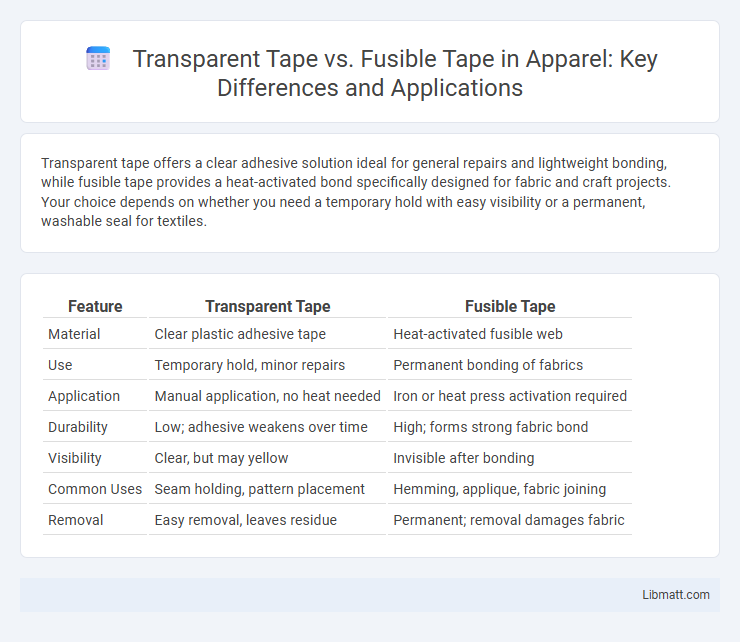

Transparent tape offers a clear adhesive solution ideal for general repairs and lightweight bonding, while fusible tape provides a heat-activated bond specifically designed for fabric and craft projects. Your choice depends on whether you need a temporary hold with easy visibility or a permanent, washable seal for textiles.

Table of Comparison

| Feature | Transparent Tape | Fusible Tape |

|---|---|---|

| Material | Clear plastic adhesive tape | Heat-activated fusible web |

| Use | Temporary hold, minor repairs | Permanent bonding of fabrics |

| Application | Manual application, no heat needed | Iron or heat press activation required |

| Durability | Low; adhesive weakens over time | High; forms strong fabric bond |

| Visibility | Clear, but may yellow | Invisible after bonding |

| Common Uses | Seam holding, pattern placement | Hemming, applique, fabric joining |

| Removal | Easy removal, leaves residue | Permanent; removal damages fabric |

Introduction to Transparent Tape and Fusible Tape

Transparent tape, commonly made from materials like cellulose or polypropylene, is widely used for sealing, repairing, and packaging due to its clarity and adhesive properties. Fusible tape, often composed of fibers embedded with heat-activated adhesive, serves a specialized role in fabric bonding and hemming without sewing. Both tapes differ significantly in function, with transparent tape excelling in general adhesive applications and fusible tape catering to textile crafts through thermal fusion.

Definition and Composition of Transparent Tape

Transparent tape, commonly known as clear adhesive tape, consists of a thin plastic film such as cellulose acetate or polypropylene coated with a pressure-sensitive acrylic or rubber-based adhesive. Its primary purpose is to provide an invisible and strong bond for general use, such as sealing, repairing, and mounting. Unlike fusible tape, transparent tape lacks heat-activated features, relying solely on adhesive stickiness for attachment.

Definition and Composition of Fusible Tape

Fusible tape, unlike transparent tape, is a heat-activated adhesive tape composed of a polyester film coated with a fusible adhesive, typically made from thermoplastic resins. It bonds fabrics by melting the adhesive layer when heat is applied, creating a strong, permanent join without stitches. Your sewing projects benefit from fusible tape by providing a clean, no-sew alternative that differs significantly from the non-adhesive, pressure-sensitive transparent tape used mainly for general-purpose fastening.

Key Differences Between Transparent and Fusible Tape

Transparent tape is primarily an adhesive strip used for general sealing, packaging, and light-duty repairs, characterized by its clear, smooth texture and pressure-sensitive adhesive. Fusible tape, in contrast, contains a heat-activated adhesive layer that bonds fabric or materials upon ironing, enabling permanent, no-sew joins often used in textiles and crafts. The key difference lies in their bonding mechanisms: transparent tape adheres by stickiness without heat, while fusible tape requires heat activation to fuse materials together.

Typical Applications of Transparent Tape

Transparent tape is commonly used for sealing envelopes, wrapping gifts, and repairing torn paper due to its clear appearance and easy application. It is a preferred choice in offices and schools for everyday tasks such as attaching documents and packaging minor items. Unlike fusible tape, which bonds fabrics using heat, transparent tape provides a quick, non-permanent adhesive solution for lightweight materials.

Typical Applications of Fusible Tape

Fusible tape is primarily used in fabric and textile projects where a temporary or permanent bond is needed without sewing, such as hemming garments, attaching appliques, and securing interfacing. It is ideal for quick repairs, crafts, and quilting, offering a clean finish without visible stitching. Unlike transparent tape, fusible tape provides a heat-activated adhesive that ensures durability and flexibility in clothing and fabric assemblies.

Advantages and Disadvantages of Transparent Tape

Transparent tape offers strong adhesion and clear visibility, making it ideal for sealing, repairing, and packaging without affecting the appearance of surfaces. Its disadvantages include limited heat resistance and durability compared to fusible tape, which is designed to bond fabrics through heat activation. Transparent tape is less suitable for textile applications but excels in general-purpose use due to its ease of application and removability.

Advantages and Disadvantages of Fusible Tape

Fusible tape offers the advantage of creating strong, permanent bonds between fabrics without sewing, making it ideal for quick repairs and projects requiring clean finishes. It can save time and maintain fabric integrity by eliminating needle holes, but it may cause stiffness and is less effective on certain textured or stretchy materials. A notable disadvantage is its dependence on heat activation, which can damage delicate fabrics or cause uneven adhesion if applied improperly.

Choosing the Right Tape for Your Project

Choosing the right tape depends on your project's requirements: transparent tape offers clear, adhesive backing ideal for temporary holds and visible surfaces, while fusible tape contains heat-activated adhesive perfect for fabric bonding and permanent seams. Transparent tape excels in paper crafts or light repairs, providing easy application without altering appearance. Fusible tape is essential in sewing and quilting projects, ensuring strong, seamless attachments that withstand washing and wear.

Conclusion: Which Tape is Best for Your Needs

Transparent tape offers a versatile adhesive solution ideal for everyday repairs, packaging, and crafting with its clear finish and strong hold. Fusible tape provides a specialized bonding option for fabric projects, enabling easy, no-sew hems and applications through heat activation. Choosing between transparent and fusible tape depends on whether you need durable adhesion for general use or a heat-activated bond for textiles.

transparent tape vs fusible tape Infographic

libmatt.com

libmatt.com