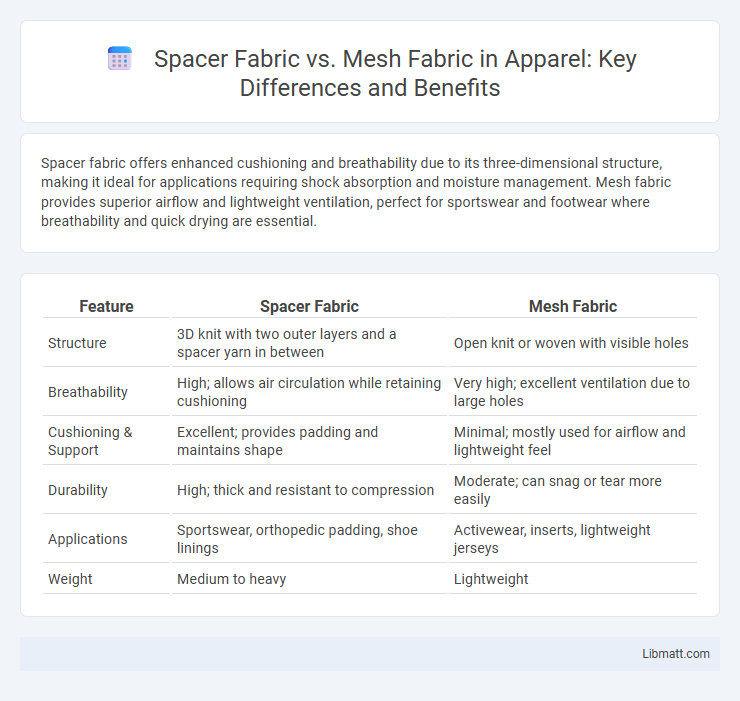

Spacer fabric offers enhanced cushioning and breathability due to its three-dimensional structure, making it ideal for applications requiring shock absorption and moisture management. Mesh fabric provides superior airflow and lightweight ventilation, perfect for sportswear and footwear where breathability and quick drying are essential.

Table of Comparison

| Feature | Spacer Fabric | Mesh Fabric |

|---|---|---|

| Structure | 3D knit with two outer layers and a spacer yarn in between | Open knit or woven with visible holes |

| Breathability | High; allows air circulation while retaining cushioning | Very high; excellent ventilation due to large holes |

| Cushioning & Support | Excellent; provides padding and maintains shape | Minimal; mostly used for airflow and lightweight feel |

| Durability | High; thick and resistant to compression | Moderate; can snag or tear more easily |

| Applications | Sportswear, orthopedic padding, shoe linings | Activewear, inserts, lightweight jerseys |

| Weight | Medium to heavy | Lightweight |

Introduction to Spacer Fabric and Mesh Fabric

Spacer fabric consists of two separate fabric layers connected by a three-dimensional knit structure, providing excellent breathability and cushioning for applications in sportswear, footwear, and medical supports. Mesh fabric features an open weave or knit pattern that allows maximum airflow and moisture wicking, commonly used in athletic apparel, bags, and outdoor gear. Both fabrics optimize comfort and ventilation but differ in structure, thickness, and specific use cases based on their unique design properties.

Structural Differences Between Spacer and Mesh Fabrics

Spacer fabric consists of two separate fabric layers held apart by a layer of monofilament yarns, creating a three-dimensional structure that provides thickness, cushioning, and enhanced breathability. Mesh fabric features a single layer with an open, net-like construction formed by interlaced yarns, promoting maximum airflow and lightweight properties but lacking the cushioning effect of spacer fabric. The unique structural design of spacer fabric offers superior shock absorption and support, while mesh fabric prioritizes ventilation and flexibility.

Key Material Properties: Spacer vs Mesh Fabrics

Spacer fabric features a three-dimensional structure with two separate fabric layers connected by a spacer yarn, offering enhanced breathability, cushioning, and support ideal for sportswear and medical applications. Mesh fabric consists of a network of open holes created by knitting or weaving, providing superior ventilation and lightweight characteristics primarily used in activewear and footwear. Spacer fabrics excel in durability and shock absorption, whereas mesh fabrics prioritize airflow and moisture management.

Breathability and Comfort Comparison

Spacer fabric offers superior breathability due to its innovative 3D structure that promotes continuous air circulation, reducing heat and moisture buildup during extended wear. Mesh fabric provides good ventilation through its open-weave design but may lack the cushioning and moisture-wicking properties found in spacer fabric. Your choice between these fabrics should consider whether you prioritize enhanced airflow with added comfort and support or simply need lightweight, breathable material.

Durability and Longevity Analysis

Spacer fabric offers superior durability and longevity compared to mesh fabric due to its multi-layered structure that resists wear, tear, and deformation over time. Mesh fabric, while breathable and lightweight, tends to fray and lose shape more quickly under continuous use and stress. Choosing spacer fabric for your projects ensures long-lasting performance and maintains structural integrity in demanding conditions.

Common Applications of Spacer Fabrics

Spacer fabrics are commonly used in automotive seating, sportswear, and orthopedic products due to their excellent cushioning and breathability. Their 3D structure provides superior ventilation and shock absorption, making them ideal for footwear insoles and mattress covers. In contrast, mesh fabrics are favored for athletic apparel, backpacks, and upholstery, where lightweight, durability, and high airflow are essential.

Common Applications of Mesh Fabrics

Mesh fabrics are extensively used in sportswear for their breathability and moisture-wicking properties, making them ideal for jerseys and athletic shoes. They are common in outdoor gear such as backpacks and camping equipment due to their lightweight structure and durability. Additionally, mesh fabrics serve in automotive seat covers and medical textiles where ventilation and comfort are crucial.

Cost Considerations: Spacer vs Mesh Fabrics

Spacer fabric generally incurs higher production costs than mesh fabric due to its complex three-dimensional construction requiring advanced technology and more raw materials. Mesh fabric, being simpler and lighter, offers a more budget-friendly option for projects where breathability and flexibility are paramount. When managing your project's budget, choosing mesh fabric can reduce expenses without significantly sacrificing comfort in many applications.

Sustainability and Environmental Impact

Spacer fabric offers enhanced sustainability by utilizing less material while providing superior breathability and cushioning, reducing the need for additional padding or layers. Mesh fabric, often made from synthetic fibers, can contribute to microplastic pollution but is lightweight and recyclable, promoting a lower environmental footprint when processed responsibly. Choosing spacer fabric can support eco-friendly manufacturing through efficient resource use and extended product lifespan, minimizing waste compared to traditional mesh alternatives.

Choosing the Right Fabric: Spacer or Mesh?

Spacer fabric offers superior cushioning and breathability due to its three-dimensional structure, making it ideal for athletic wear and upholstery requiring enhanced comfort. Mesh fabric provides excellent ventilation and lightweight durability, perfect for sports jerseys and outdoor gear where airflow is a priority. Your choice depends on whether you prioritize padded support with moisture management (spacer) or lightweight breathability and quick drying (mesh).

spacer fabric vs mesh fabric Infographic

libmatt.com

libmatt.com