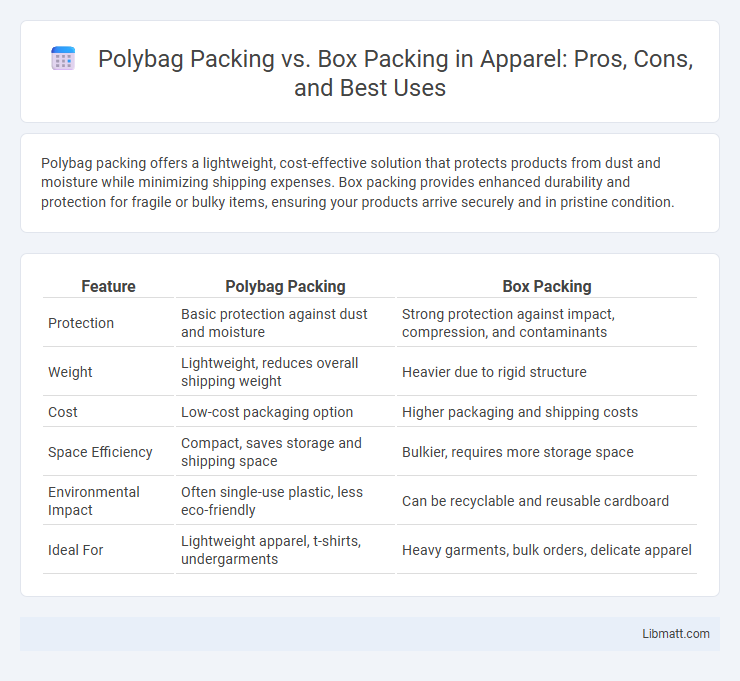

Polybag packing offers a lightweight, cost-effective solution that protects products from dust and moisture while minimizing shipping expenses. Box packing provides enhanced durability and protection for fragile or bulky items, ensuring your products arrive securely and in pristine condition.

Table of Comparison

| Feature | Polybag Packing | Box Packing |

|---|---|---|

| Protection | Basic protection against dust and moisture | Strong protection against impact, compression, and contaminants |

| Weight | Lightweight, reduces overall shipping weight | Heavier due to rigid structure |

| Cost | Low-cost packaging option | Higher packaging and shipping costs |

| Space Efficiency | Compact, saves storage and shipping space | Bulkier, requires more storage space |

| Environmental Impact | Often single-use plastic, less eco-friendly | Can be recyclable and reusable cardboard |

| Ideal For | Lightweight apparel, t-shirts, undergarments | Heavy garments, bulk orders, delicate apparel |

Introduction to Polybag and Box Packing

Polybag packing involves using flexible, lightweight plastic bags to protect and contain products, offering cost-effective and space-saving packaging solutions ideal for apparel, small accessories, and soft goods. Box packing utilizes rigid cardboard or corrugated containers that provide robust protection, stackability, and customization options, making it suitable for fragile or bulkier items. Choosing between polybag and box packing depends on product type, shipping requirements, and storage considerations, with polybags excelling in flexibility and boxes excelling in durability.

Key Differences Between Polybag and Box Packing

Polybag packing offers lightweight, flexible, and cost-effective protection ideal for soft goods, while box packing provides robust, structured support suitable for fragile or heavy items. Polybags maximize space efficiency and reduce shipping weight, whereas boxes enhance product security with rigid walls and cushioning options. Your choice depends on product fragility, shipping requirements, and budget constraints.

Material Composition and Sustainability

Polybag packing typically consists of lightweight polyethylene materials that consume fewer resources but can pose recycling challenges due to lower biodegradability. Box packing, often made from corrugated cardboard, is generally more sustainable as it uses renewable fibers and is widely recyclable. Your choice between polybag and box packing impacts environmental footprint, with boxes offering superior material reuse and compostability compared to most polybags.

Cost Comparison: Polybag Packing vs Box Packing

Polybag packing generally offers a lower cost due to reduced material expenses and lighter shipping weights, making it ideal for lightweight or non-fragile products. Box packing incurs higher costs because of bulkier materials, additional cushioning requirements, and increased dimensional weight charges during shipping. Your choice between polybag and box packing should consider the balance between cost savings and the level of product protection needed.

Impact on Product Protection and Safety

Polybag packing offers lightweight and flexible protection, reducing surface scratches and moisture exposure but providing limited impact resistance, making it less ideal for fragile or heavy items. Box packing ensures superior product protection by cushioning against shocks, drops, and compression during transit, significantly enhancing safety for delicate and high-value goods. Choosing between polybag and box packing depends on the product's fragility, shipping conditions, and cost-effectiveness in maintaining product integrity.

Space Efficiency and Storage Considerations

Polybag packing offers superior space efficiency by minimizing volume and allowing flexible stacking, making it ideal for storage areas with limited space. Box packing provides better protection and easier organization, but requires more storage room due to rigid structure and bulkier dimensions. Your choice depends on whether maximizing storage density or safeguarding contents is your priority.

Environmental Impact and Recycling Options

Polybag packing generates less waste and consumes fewer raw materials compared to box packing, reducing carbon footprint and landfill contributions. While polybags are often made from recyclable polyethylene, their thin nature can cause challenges in recycling processes, unlike boxes made from corrugated cardboard which are widely accepted and easily recycled through curbside programs. Choosing box packing supports a circular economy with higher recycling rates, whereas polybag recycling requires specialized facilities to effectively manage plastic waste and minimize environmental harm.

Suitability for Various Product Types

Polybag packing is ideal for lightweight, flexible products such as clothing, textiles, and small accessories, offering cost-effective protection and minimal storage space requirements. Box packing suits fragile, heavy, or irregularly shaped items like electronics, glassware, and bulk goods, providing enhanced protection during shipping and stacking. Selecting the appropriate packing method depends on product fragility, dimension, and shipping conditions to ensure optimal safety and presentation.

Packaging Regulations and Industry Standards

Polybag packing and box packing each adhere to distinct packaging regulations and industry standards that prioritize product safety and sustainability. Polybag packing must comply with regulations regarding material durability, puncture resistance, and recycling codes set by organizations such as ASTM International and the Environmental Protection Agency (EPA). Box packing standards emphasize strength, stacking durability, and moisture resistance, often following guidelines from the International Safe Transit Association (ISTA) and the Forest Stewardship Council (FSC) certification for sustainable sourcing.

Choosing the Right Packing Method for Your Business

Polybag packing offers cost-effective, lightweight, and space-saving solutions ideal for soft goods and apparel, while box packing provides superior protection, organization, and branding opportunities for fragile or high-value products. Assess your product fragility, shipping requirements, and branding goals to determine the optimal packing method. Businesses prioritizing durability and presentation may prefer box packing, whereas those focusing on reducing shipping costs and volume could benefit from polybag packing.

Polybag Packing vs Box Packing Infographic

libmatt.com

libmatt.com