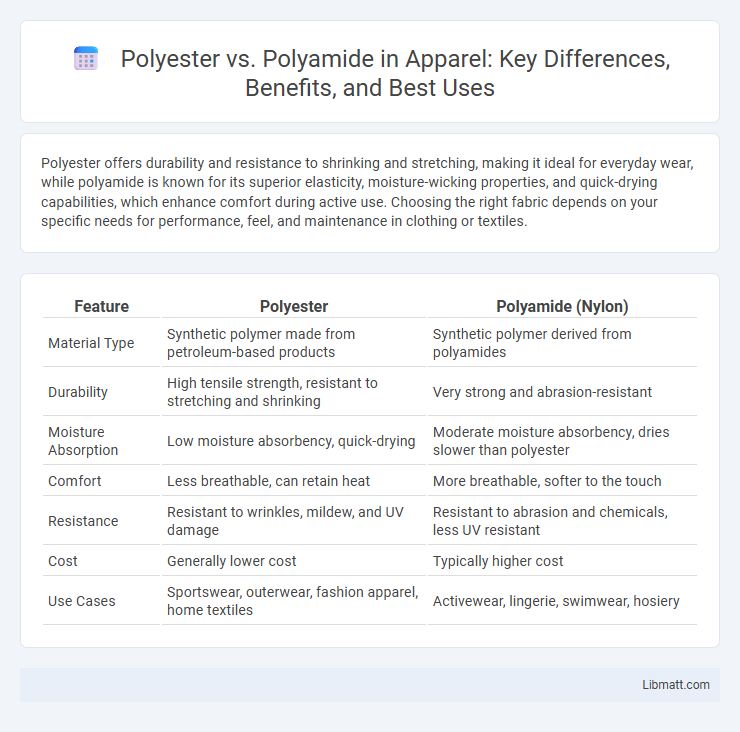

Polyester offers durability and resistance to shrinking and stretching, making it ideal for everyday wear, while polyamide is known for its superior elasticity, moisture-wicking properties, and quick-drying capabilities, which enhance comfort during active use. Choosing the right fabric depends on your specific needs for performance, feel, and maintenance in clothing or textiles.

Table of Comparison

| Feature | Polyester | Polyamide (Nylon) |

|---|---|---|

| Material Type | Synthetic polymer made from petroleum-based products | Synthetic polymer derived from polyamides |

| Durability | High tensile strength, resistant to stretching and shrinking | Very strong and abrasion-resistant |

| Moisture Absorption | Low moisture absorbency, quick-drying | Moderate moisture absorbency, dries slower than polyester |

| Comfort | Less breathable, can retain heat | More breathable, softer to the touch |

| Resistance | Resistant to wrinkles, mildew, and UV damage | Resistant to abrasion and chemicals, less UV resistant |

| Cost | Generally lower cost | Typically higher cost |

| Use Cases | Sportswear, outerwear, fashion apparel, home textiles | Activewear, lingerie, swimwear, hosiery |

Introduction to Polyester and Polyamide

Polyester and polyamide are two prominent synthetic fibers widely used in textile manufacturing. Polyester, derived from petrochemical compounds, is known for its durability, wrinkle resistance, and quick-drying properties. Polyamide, commonly referred to as nylon, offers superior elasticity, abrasion resistance, and moisture-wicking capabilities, making it ideal for activewear and outdoor gear.

Chemical Composition and Structure

Polyester is composed of repeating units of ester-functional groups derived from terephthalic acid and ethylene glycol, resulting in a semicrystalline thermoplastic polymer with strong intermolecular hydrogen bonds. Polyamide, commonly known as nylon, consists of amide linkages formed by the polymerization of diamines and dicarboxylic acids, giving it a more flexible and crystalline structure with high tensile strength. Understanding these chemical compositions allows You to choose the right material based on desired durability, elasticity, and resistance properties.

Production Processes Compared

Polyester production primarily involves the polymerization of ethylene glycol and terephthalic acid, resulting in a synthetic fiber valued for its durability and resistance to shrinking and stretching. Polyamide, often known as nylon, is produced through the polymerization of hexamethylene diamine and adipic acid, creating a strong, elastic fiber commonly used in textiles and engineering materials. Understanding these distinct production processes helps you choose the right fabric based on your needs for strength, elasticity, and chemical resistance.

Durability and Strength Differences

Polyamide fibers, commonly known as nylon, exhibit superior strength and elasticity compared to polyester, making them more resistant to abrasion and wear under high-stress conditions. Polyester offers excellent durability with strong resistance to UV damage and moisture, ensuring long-lasting performance in outdoor applications. Your choice between polyester and polyamide should consider the specific durability demands of your project, as polyamide excels in tensile strength while polyester provides enhanced weather resistance.

Moisture Absorption and Breathability

Polyamide offers superior moisture absorption and breathability compared to polyester, making it ideal for activewear and outdoor clothing. Polyester tends to repel water, causing sweat to sit on the skin, which can lead to discomfort and slower evaporation. Polyamide's hydrophilic properties allow it to wick moisture away efficiently, enhancing comfort in humid or high-intensity environments.

Comfort and Wearability Factors

Polyester offers excellent moisture-wicking properties and durability, making it ideal for activewear but may feel less breathable and trap heat during prolonged wear. Polyamide, commonly known as nylon, provides superior softness, elasticity, and breathability, enhancing comfort for everyday garments and close-to-skin applications. Both fibers demonstrate strong abrasion resistance, but polyamide tends to provide a lighter, more flexible fit that improves overall wearability.

Environmental Impact and Sustainability

Polyester, primarily derived from petrochemicals, has a significant environmental impact due to its energy-intensive production and slow biodegradability, contributing to microplastic pollution in oceans. Polyamide, especially nylon, requires substantial fossil fuel use and emits nitrous oxide, a potent greenhouse gas, but innovations in bio-based polyamides are improving sustainability profiles. Recycling technologies for both fibers are advancing, yet polyester recycling is more established, making it a relatively more sustainable option when utilizing post-consumer recycled content.

Common Applications in Industry

Polyester is widely used in apparel, home textiles, and industrial fabrics due to its durability, resistance to stretching, and quick-drying properties. Polyamide, commonly known as nylon, is favored in automotive parts, outdoor gear, and high-performance sportswear because of its superior abrasion resistance and elasticity. Your choice between polyester and polyamide should consider the specific application requirements such as strength, flexibility, and environmental exposure.

Cost and Market Availability

Polyester dominates the textile market due to its lower production costs and widespread availability, making it a more budget-friendly option for manufacturers and consumers. Polyamide, while generally more expensive due to complex manufacturing processes and specialty applications, offers superior strength and elasticity, which drives demand in performance-focused markets. Global polyester production exceeds 50 million tons annually, significantly outpacing polyamide production, which remains limited to approximately 3 million tons, reflecting its niche market presence.

Choosing Between Polyester and Polyamide

Choosing between polyester and polyamide depends on the desired fabric properties and end-use applications. Polyester offers excellent durability, wrinkle resistance, and moisture-wicking capabilities, making it ideal for sportswear and outdoor gear. Polyamide, commonly known as nylon, provides superior elasticity, abrasion resistance, and quick-drying features, which suit swimwear, hosiery, and performance clothing.

Polyester vs Polyamide Infographic

libmatt.com

libmatt.com