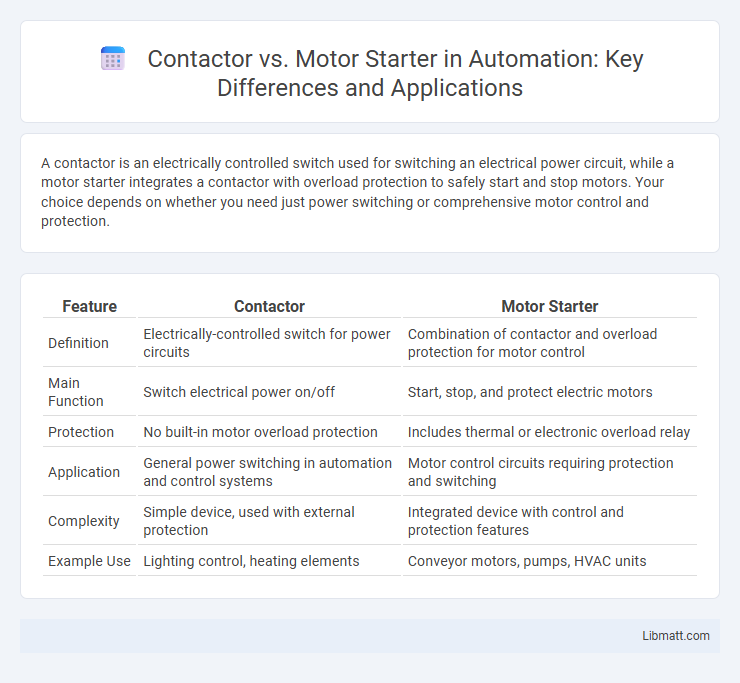

A contactor is an electrically controlled switch used for switching an electrical power circuit, while a motor starter integrates a contactor with overload protection to safely start and stop motors. Your choice depends on whether you need just power switching or comprehensive motor control and protection.

Table of Comparison

| Feature | Contactor | Motor Starter |

|---|---|---|

| Definition | Electrically-controlled switch for power circuits | Combination of contactor and overload protection for motor control |

| Main Function | Switch electrical power on/off | Start, stop, and protect electric motors |

| Protection | No built-in motor overload protection | Includes thermal or electronic overload relay |

| Application | General power switching in automation and control systems | Motor control circuits requiring protection and switching |

| Complexity | Simple device, used with external protection | Integrated device with control and protection features |

| Example Use | Lighting control, heating elements | Conveyor motors, pumps, HVAC units |

Overview of Contactors and Motor Starters

Contactors are electrically controlled switches used for switching a power circuit, primarily in motor control applications, capable of handling high current loads. Motor starters combine a contactor with protective devices such as overload relays to safely start and stop electric motors while preventing damage from electrical faults. These components are essential in industrial automation for managing motor operation and ensuring equipment safety.

Definition and Core Functions

A contactor is an electrically controlled switch used for switching an electrical power circuit, primarily designed to handle high current loads with rapid on/off capabilities. A motor starter combines a contactor with overload protection devices to safely start and stop electric motors while preventing damage from electrical faults. Understanding the differences in definition and core functions helps you select the right component for motor control and protection in your electrical system.

Key Differences Between Contactors and Motor Starters

Contactors primarily function as electrically controlled switches used for switching power circuits, whereas motor starters combine contactors and overload protection to safely initiate and control motor operation. Key differences include the presence of built-in overload relays in motor starters to prevent motor damage, a feature absent in standard contactors. Motor starters offer enhanced safety and motor protection, making them essential for motor applications beyond mere switching capabilities.

Working Principles Explained

A contactor operates by using an electromagnetic coil to open or close electrical contacts, allowing or interrupting the flow of current in a circuit. A motor starter combines a contactor with an overload relay to both switch the motor on or off and protect it from electrical overload conditions. The core difference lies in the motor starter's added function of motor protection alongside the contactor's primary switching capability.

Components and Construction

Contactor and motor starter differ significantly in components and construction; a contactor primarily consists of an electromagnet, stationary and movable contacts, and an arc suppression mechanism designed for frequent switching operations. In contrast, a motor starter incorporates a contactor along with an overload relay, providing protection against motor overcurrent and thermal overload conditions. The robust construction of motor starters integrates control and protective functions, making them essential for safe motor operation and longevity.

Applications in Industrial Settings

Contactors are widely used in industrial settings to control electric motors, lighting, and heating circuits due to their ability to handle high current loads and frequent switching. Motor starters combine contactors with overload protection, making them essential for safely starting and stopping motors while preventing damage from electrical overloads. Your choice between a contactor and a motor starter depends on whether you need simple power control or integrated motor protection in your industrial applications.

Advantages and Limitations

Contactors offer high durability and easy remote control for frequent switching in industrial applications, yet they lack built-in overload protection, requiring separate devices for motor safety. Motor starters combine contactors with overload relays, providing comprehensive motor protection and simplifying wiring, but they are generally bulkier and more expensive. While contactors excel in cost-efficiency and flexibility for controlling multiple loads, motor starters ensure enhanced safety and reliability by preventing motor damage due to overload conditions.

Selection Criteria for Electrical Systems

When selecting between a contactor and a motor starter for electrical systems, consider the load current, control complexity, and safety requirements. Contactors are suitable for simple on/off switching of motors, while motor starters provide overload protection and enhanced control features essential for safeguarding your equipment. Your choice should align with system voltage, motor size, and application-specific demands to ensure reliable operation and compliance with electrical standards.

Safety Features and Protective Mechanisms

Contactor and motor starter both incorporate essential safety features, but motor starters provide enhanced protective mechanisms such as overload protection, short circuit protection, and under-voltage release to safeguard motors and circuits. Contactors primarily serve as on/off switches with basic electrical isolation, while motor starters integrate thermal or electronic overload relays to prevent motor damage from excessive current. Understanding these differences helps you choose the appropriate device for reliable motor control and safety compliance.

Maintenance and Troubleshooting Tips

Regular inspection of contactors involves checking for signs of wear, such as pitted contacts or coil damage, to prevent electrical failures, while motor starters require monitoring of overload relays and connections to avoid motor overheating. Proper maintenance includes cleaning dust and debris from contact points and ensuring tight terminal connections to maintain optimal performance. When troubleshooting, use a multimeter to verify coil voltage and continuity in both devices, and observe any abnormal noises or heat generation that may indicate underlying mechanical or electrical issues affecting Your system's reliability.

Contactor vs Motor Starter Infographic

libmatt.com

libmatt.com