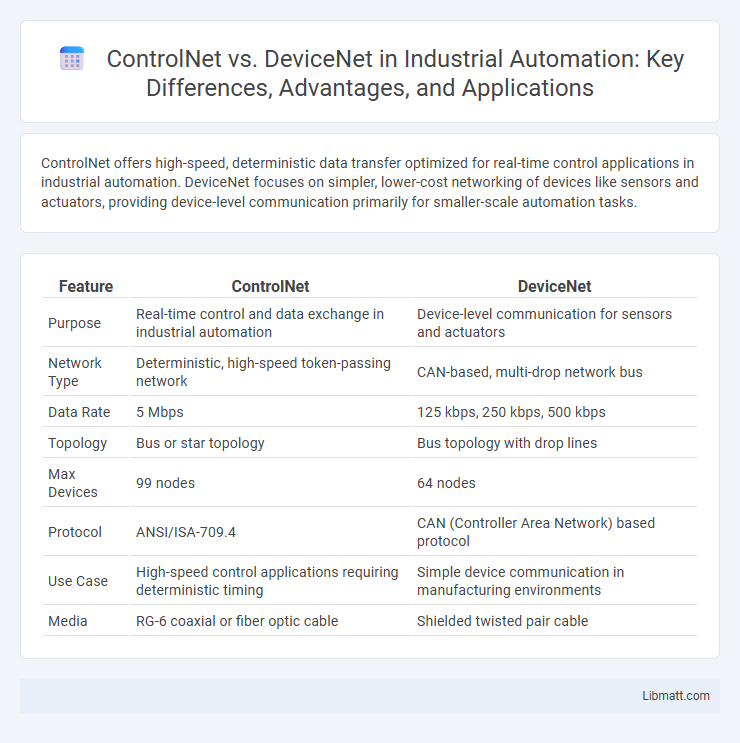

ControlNet offers high-speed, deterministic data transfer optimized for real-time control applications in industrial automation. DeviceNet focuses on simpler, lower-cost networking of devices like sensors and actuators, providing device-level communication primarily for smaller-scale automation tasks.

Table of Comparison

| Feature | ControlNet | DeviceNet |

|---|---|---|

| Purpose | Real-time control and data exchange in industrial automation | Device-level communication for sensors and actuators |

| Network Type | Deterministic, high-speed token-passing network | CAN-based, multi-drop network bus |

| Data Rate | 5 Mbps | 125 kbps, 250 kbps, 500 kbps |

| Topology | Bus or star topology | Bus topology with drop lines |

| Max Devices | 99 nodes | 64 nodes |

| Protocol | ANSI/ISA-709.4 | CAN (Controller Area Network) based protocol |

| Use Case | High-speed control applications requiring deterministic timing | Simple device communication in manufacturing environments |

| Media | RG-6 coaxial or fiber optic cable | Shielded twisted pair cable |

Introduction to ControlNet and DeviceNet

ControlNet and DeviceNet are industrial communication protocols designed for real-time data exchange in automation systems. ControlNet offers high-speed, deterministic networking ideal for time-critical applications, while DeviceNet provides a cost-effective, simple solution for connecting sensors, actuators, and other devices on a device level. Understanding these protocols helps you select the right network architecture to optimize your industrial control system's efficiency and reliability.

Key Differences Between ControlNet and DeviceNet

ControlNet offers high-speed, deterministic control for real-time applications, whereas DeviceNet is designed for lower-speed device-level communication with simpler wiring. ControlNet supports larger data packets and longer cable lengths, making it suitable for complex automation networks, while DeviceNet excels in connecting sensors and actuators on the plant floor. Understanding these key differences helps you select the optimal network for your industrial control system needs.

Network Architecture Overview

ControlNet features a deterministic, high-speed network architecture designed for real-time control applications, utilizing a coaxial cable backbone with repeaters and taps to connect devices in a linear or star topology. DeviceNet employs a simpler, low-speed CAN-based network architecture with a trunkline and drop-line topology, ideal for device-level networking in industrial automation. ControlNet's architecture supports synchronized data transfer and scheduled communication, while DeviceNet emphasizes ease of device integration and cost-effectiveness.

Communication Protocols Compared

ControlNet and DeviceNet are industrial communication protocols designed for real-time control in manufacturing environments, but they differ significantly in architecture and data handling. ControlNet operates on a deterministic, high-speed token-passing network ideal for large data transfers and synchronized control, while DeviceNet utilizes a Controller Area Network (CAN) bus that supports simpler, lower-speed messaging for device-level communication. Choosing between these protocols depends on Your system's scalability needs, data throughput requirements, and complexity of device integration in automated processes.

Data Transfer Speed and Bandwidth

ControlNet offers a data transfer speed of up to 5 Mbps, optimized for real-time, high-speed communication in industrial automation systems. DeviceNet operates at a lower speed of 125 kbps to 500 kbps, prioritizing device-level communication with moderate bandwidth requirements. Your choice between ControlNet and DeviceNet should depend on whether higher data throughput or broader device integration with lower bandwidth suffices for your application.

Device Compatibility and Integration

ControlNet supports real-time, high-speed communication primarily for industrial automation networks, offering seamless integration with Allen-Bradley devices and Rockwell Automation systems. DeviceNet, based on the CAN protocol, provides broad compatibility with a wide range of field devices like sensors, actuators, and motor controllers from multiple manufacturers due to its open standard nature. Integration of ControlNet is optimized for complex, high-bandwidth control tasks, whereas DeviceNet excels in connecting numerous distributed I/O devices in cost-effective, lower-speed applications.

Scalability and Network Expansion

ControlNet offers high scalability with deterministic, real-time data transfer ideal for complex industrial automation systems requiring tight synchronization. DeviceNet supports moderate scalability using a Controller Area Network (CAN) bus, facilitating easier network expansion but with lower bandwidth and longer update intervals. ControlNet's architecture accommodates larger networks with up to 99 nodes per segment, whereas DeviceNet typically supports up to 64 nodes, making ControlNet better suited for extensive, high-performance applications.

Application Areas and Use Cases

ControlNet excels in real-time, high-speed control applications such as factory automation, robotics, and process control systems, supporting deterministic data transfer and time-sensitive networking. DeviceNet is widely used in industrial automation for device-level communication, connecting sensors, actuators, and motor controllers within manufacturing environments. Your choice between ControlNet and DeviceNet should align with the required network speed, complexity, and the level of control precision needed for your specific automation tasks.

Reliability, Safety, and Maintenance

ControlNet offers high reliability through its deterministic, real-time communication protocol, ensuring consistent data transfer suitable for critical industrial automation. DeviceNet emphasizes safety with built-in features like device-level fault detection and straightforward diagnostics, reducing downtime and enhancing operational security. Maintenance demands for ControlNet involve advanced network monitoring and configuration, whereas DeviceNet supports easier troubleshooting and lower maintenance costs due to its simpler architecture and widespread adoption.

Choosing the Right Network for Industrial Automation

ControlNet offers deterministic real-time data transfer with high-speed performance suited for time-critical industrial automation tasks, while DeviceNet provides cost-effective, simple network solutions ideal for connecting control devices like sensors and actuators. Selecting ControlNet is optimal for complex and large-scale systems demanding precise synchronization and high data throughput, whereas DeviceNet excels in smaller, distributed applications requiring ease of installation and lower wiring complexity. Evaluating factors such as network size, speed requirements, device compatibility, and budget constraints is crucial in choosing the right network for efficient industrial automation.

ControlNet vs DeviceNet Infographic

libmatt.com

libmatt.com