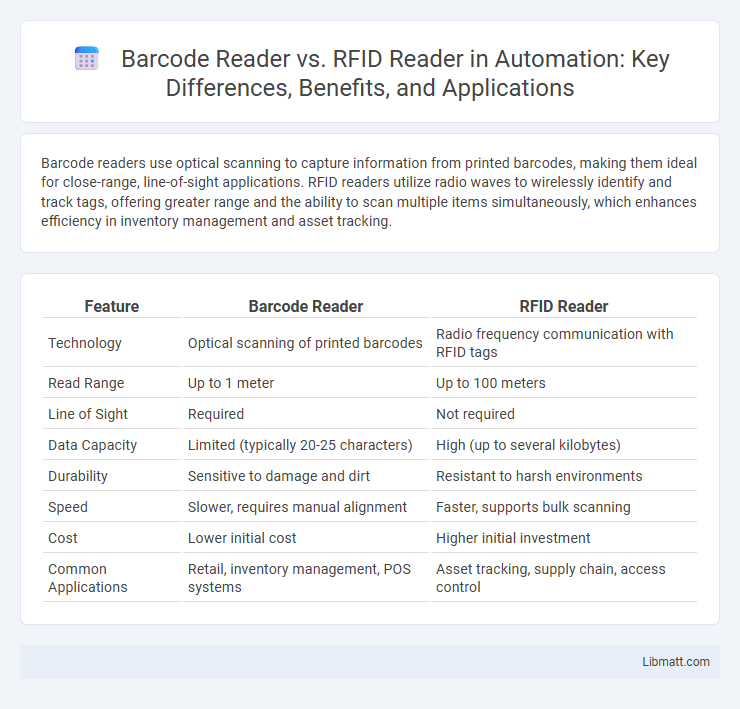

Barcode readers use optical scanning to capture information from printed barcodes, making them ideal for close-range, line-of-sight applications. RFID readers utilize radio waves to wirelessly identify and track tags, offering greater range and the ability to scan multiple items simultaneously, which enhances efficiency in inventory management and asset tracking.

Table of Comparison

| Feature | Barcode Reader | RFID Reader |

|---|---|---|

| Technology | Optical scanning of printed barcodes | Radio frequency communication with RFID tags |

| Read Range | Up to 1 meter | Up to 100 meters |

| Line of Sight | Required | Not required |

| Data Capacity | Limited (typically 20-25 characters) | High (up to several kilobytes) |

| Durability | Sensitive to damage and dirt | Resistant to harsh environments |

| Speed | Slower, requires manual alignment | Faster, supports bulk scanning |

| Cost | Lower initial cost | Higher initial investment |

| Common Applications | Retail, inventory management, POS systems | Asset tracking, supply chain, access control |

Introduction to Barcode Readers and RFID Readers

Barcode readers use optical technology to scan and interpret black-and-white patterns representing data, commonly found in retail and inventory management for quick item identification. RFID readers employ radio frequency signals to read information stored on embedded microchips within tags, enabling contactless and real-time tracking of assets across various industries. Both systems optimize automated data capture but differ significantly in range, data capacity, and environmental adaptability.

How Barcode Readers Work

Barcode readers use optical technology to scan and decode printed barcodes by emitting a light source, usually a laser, that reflects off the barcode's black and white patterns. The sensor captures the reflected light variations, converting them into electrical signals that a decoder translates into data recognizable by your system. Unlike RFID readers, barcode readers require a direct line of sight to capture the barcode information accurately.

How RFID Readers Work

RFID readers operate by emitting radio waves to communicate with RFID tags, which contain electronically stored information. When your RFID tag passes within the reader's range, it receives the signal and transmits its unique data back to the reader without needing direct line-of-sight, unlike barcode readers. This wireless technology enables faster, automated scanning and inventory tracking in dynamic environments.

Key Differences Between Barcode and RFID Readers

Barcode readers scan visual patterns of black and white lines to decode data, while RFID readers use radio waves to identify and track tags wirelessly without direct line of sight. Barcode readers require close proximity and alignment to the code, whereas RFID readers can scan multiple tags simultaneously from a distance, enhancing efficiency in inventory management. Your choice depends on the application's need for speed, range, and environment, with RFID readers offering greater flexibility and durability compared to barcode systems.

Advantages of Barcode Readers

Barcode readers offer cost-effective solutions with simple implementation and widespread compatibility across retail and inventory systems. Their ability to accurately scan printed labels without radio frequency interference ensures reliable data capture in diverse environments. Low maintenance requirements and the availability of handheld and fixed-mount devices contribute to their operational flexibility.

Benefits of RFID Readers

RFID readers offer significant advantages over barcode readers by enabling non-line-of-sight scanning, allowing multiple tags to be read simultaneously from a distance. RFID technology provides faster data capture and higher accuracy, reducing human error in inventory management and tracking applications. Enhanced durability and the ability to withstand harsh environments make RFID readers ideal for diverse industries such as logistics, retail, and manufacturing.

Common Applications for Each Technology

Barcode readers are commonly used in retail checkout, inventory management, and shipping logistics for rapid and accurate scanning of product information. RFID readers, leveraging radio frequency waves, excel in asset tracking, supply chain management, and access control systems by enabling contactless and bulk reading capabilities. Your choice between these technologies depends on specific application needs like read range, environmental conditions, and data capacity.

Security and Data Accuracy Comparison

Barcode readers rely on optical scanning of printed codes, which can be easily duplicated or damaged, leading to potential security vulnerabilities and lower data accuracy in challenging environments. RFID readers use radio waves to scan tags without direct line-of-sight, providing enhanced security features such as encryption and authentication, resulting in higher data accuracy and reduced risk of fraud. Your choice between these technologies impacts the integrity and protection of sensitive information in applications like inventory management and asset tracking.

Cost and Implementation Considerations

Barcode readers generally offer lower upfront costs and simpler implementation compared to RFID readers, making them ideal for budget-conscious projects with straightforward scanning requirements. RFID readers require higher initial investment due to the complexity of hardware, software, and integration with existing systems but provide benefits in automation and real-time asset tracking. Implementation of RFID also demands more technical expertise for setup and maintenance, while barcode systems are easier to deploy and support with minimal training.

Choosing the Right Technology for Your Business

Selecting between a barcode reader and an RFID reader depends on factors like scanning speed, range, and environmental conditions. Barcode readers excel in cost-effectiveness and ease of use for inventory with visible labels, while RFID readers offer faster, hands-free data capture and better durability in challenging environments. Businesses should assess product tracking needs, budget constraints, and operational efficiency goals to determine the most suitable technology.

Barcode Reader vs RFID Reader Infographic

libmatt.com

libmatt.com