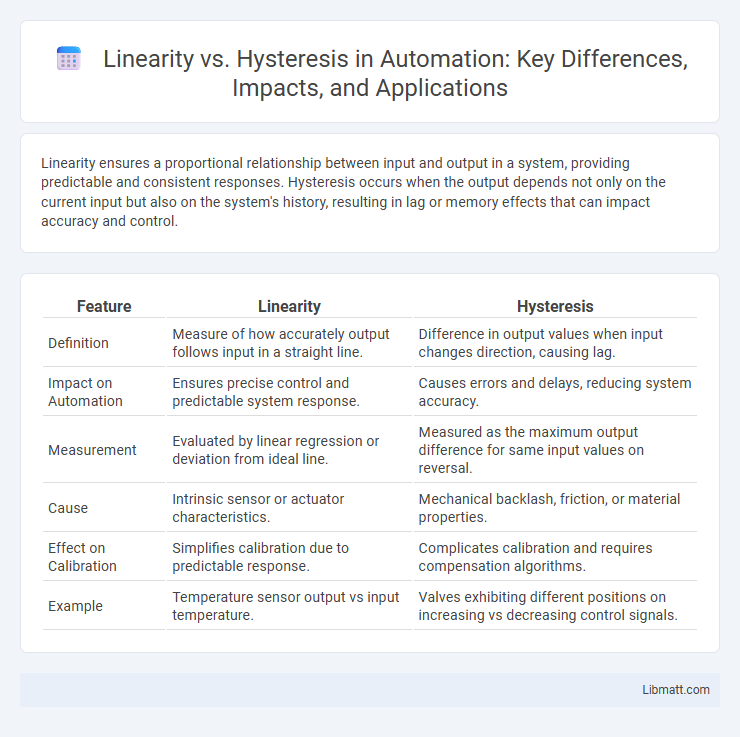

Linearity ensures a proportional relationship between input and output in a system, providing predictable and consistent responses. Hysteresis occurs when the output depends not only on the current input but also on the system's history, resulting in lag or memory effects that can impact accuracy and control.

Table of Comparison

| Feature | Linearity | Hysteresis |

|---|---|---|

| Definition | Measure of how accurately output follows input in a straight line. | Difference in output values when input changes direction, causing lag. |

| Impact on Automation | Ensures precise control and predictable system response. | Causes errors and delays, reducing system accuracy. |

| Measurement | Evaluated by linear regression or deviation from ideal line. | Measured as the maximum output difference for same input values on reversal. |

| Cause | Intrinsic sensor or actuator characteristics. | Mechanical backlash, friction, or material properties. |

| Effect on Calibration | Simplifies calibration due to predictable response. | Complicates calibration and requires compensation algorithms. |

| Example | Temperature sensor output vs input temperature. | Valves exhibiting different positions on increasing vs decreasing control signals. |

Introduction to Linearity and Hysteresis

Linearity describes a system where the output changes proportionally to the input, ensuring predictable and consistent behavior across the operating range. Hysteresis occurs when the output depends not only on the current input but also on the history of past inputs, causing lag or deviation in response. Understanding the difference between linearity and hysteresis is crucial for accurately interpreting sensor data and optimizing Your system's performance.

Defining Linearity in Systems

Linearity in systems refers to a direct proportional relationship between input and output, characterized by the principle of superposition where the response to a sum of inputs equals the sum of the responses to each input separately. This means that doubling the input results in a doubling of the output, ensuring predictability and consistency in system behavior. Your system's linearity is crucial for accurate modeling, control, and signal processing applications, where deviations could lead to errors and inefficiencies.

Understanding Hysteresis: Key Concepts

Hysteresis refers to the phenomenon where the output of a system depends not only on its current input but also on its previous states, creating a looped response curve characteristic in materials like ferromagnets and mechanical systems. Unlike linearity, which implies a direct proportionality and consistent input-output relationship, hysteresis introduces energy loss and delays due to internal friction or memory effects within the system. This behavior is critical in designing sensors, actuators, and control systems where precise feedback and stability are required despite the nonlinear, path-dependent responses.

Mathematical Representation of Linearity

Linearity in mathematical terms is defined by a direct proportionality between variables, typically expressed as y = mx + b, where m represents the slope and b the intercept. This relationship signifies that changes in the input x result in consistent and predictable changes in the output y, without path dependency or memory effects. Understanding linearity helps you design systems and models where responses are directly predictable and reversible, unlike hysteresis which introduces nonlinearity and lag effects.

The Science Behind Hysteresis Loops

Hysteresis loops represent the nonlinear relationship between input and output in systems exhibiting path-dependent behavior, commonly observed in magnetic materials and elastic deformation. These loops illustrate how the material's response depends not only on the current input but also on its history, resulting in energy loss within each cycle. Understanding hysteresis is crucial in designing efficient magnetic cores, sensors, and actuators where minimizing energy dissipation is essential.

Applications of Linear Systems

Linear systems are crucial in control engineering, signal processing, and telecommunications due to their predictable input-output relationship, which allows for straightforward analysis and design. Their applications include electronic amplifiers, where linearity ensures signal fidelity, and mechanical systems like suspension systems that require precise control without lag or memory effects. The absence of hysteresis in linear systems guarantees consistent performance, making them ideal for sensors and actuators in automation and robotics.

Real-World Examples of Hysteresis

Hysteresis occurs in magnetic materials such as transformers and electric motors, where the magnetization lags behind the applied magnetic field, causing energy loss and heat generation. In mechanical systems, hysteresis is evident in rubber bands and shock absorbers, where the response depends on the history of applied stress or strain, leading to delayed recovery and energy dissipation. Temperature control systems with thermostats exhibit hysteresis to prevent rapid cycling, maintaining set points through a range of temperatures rather than a fixed threshold.

Comparing Linearity and Hysteresis: Critical Differences

Linearity describes a direct proportional relationship between input and output, ensuring predictable and repeatable system behavior, while hysteresis involves a lagging response where output depends on input history, causing path-dependent variations. The critical difference lies in linearity's ability to maintain consistent performance during cyclic operations, whereas hysteresis introduces memory effects leading to discrepancies between increasing and decreasing input cycles. This distinction profoundly impacts sensor accuracy, control systems, and material behavior analysis in engineering applications.

Measuring Linearity and Hysteresis in Practice

Measuring linearity in sensors involves applying a known input and recording the corresponding output to determine how closely the output follows a straight line, often quantified by the linearity error percentage. Hysteresis measurement requires cycling the input signal through its range both increasing and decreasing, then comparing output differences at identical input points to quantify hysteresis error. Your calibration process benefits from precise instrumentation and repeated measurements to ensure accuracy in detecting deviations from ideal linearity and minimal hysteresis effects.

Conclusion: Choosing Between Linearity and Hysteresis

Selecting between linearity and hysteresis depends on the specific application requirements, sensor accuracy, and response behavior. Linearity ensures proportional output relative to input, vital for precise measurements, while hysteresis allows systems to withstand noise and avoid false triggers in fluctuating environments. Engineers must weigh the trade-offs between measurement precision and system stability to optimize performance.

Linearity vs Hysteresis Infographic

libmatt.com

libmatt.com