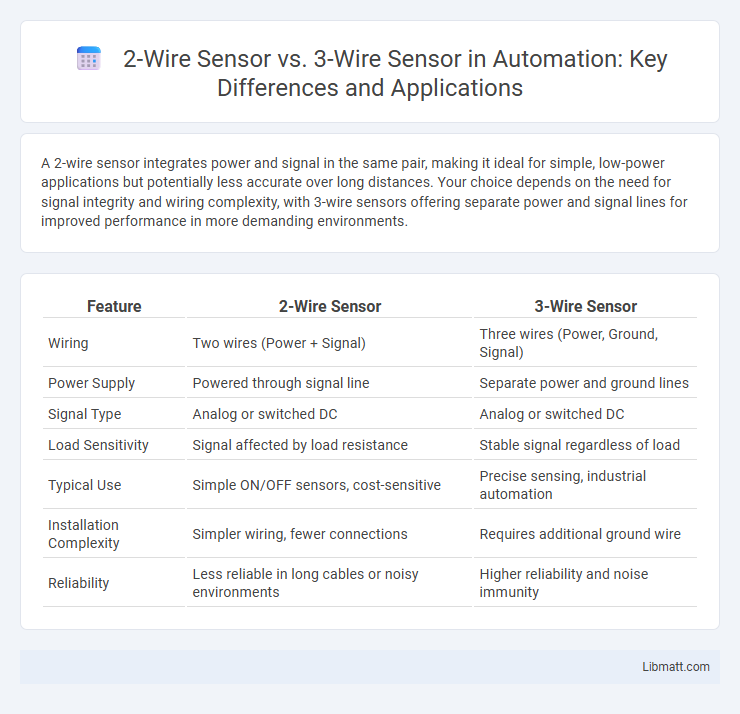

A 2-wire sensor integrates power and signal in the same pair, making it ideal for simple, low-power applications but potentially less accurate over long distances. Your choice depends on the need for signal integrity and wiring complexity, with 3-wire sensors offering separate power and signal lines for improved performance in more demanding environments.

Table of Comparison

| Feature | 2-Wire Sensor | 3-Wire Sensor |

|---|---|---|

| Wiring | Two wires (Power + Signal) | Three wires (Power, Ground, Signal) |

| Power Supply | Powered through signal line | Separate power and ground lines |

| Signal Type | Analog or switched DC | Analog or switched DC |

| Load Sensitivity | Signal affected by load resistance | Stable signal regardless of load |

| Typical Use | Simple ON/OFF sensors, cost-sensitive | Precise sensing, industrial automation |

| Installation Complexity | Simpler wiring, fewer connections | Requires additional ground wire |

| Reliability | Less reliable in long cables or noisy environments | Higher reliability and noise immunity |

Introduction to 2-Wire and 3-Wire Sensors

2-wire sensors integrate power and signal transmission into two wires, offering simplified wiring and reduced installation costs, typically used in low-power applications like proximity sensors. In contrast, 3-wire sensors separate power supply and signal lines, providing improved signal stability and compatibility with more complex control systems, common in industrial automation. Understanding the wiring configuration is critical for selecting the appropriate sensor based on system requirements for voltage, current, and signal type.

Basic Working Principle of Industrial Sensors

2-wire sensors operate using a simple loop with two connections for power and signal transmission, relying on current modulation to send data, which minimizes wiring complexity and power consumption. 3-wire sensors separate power supply and signal output by using distinct wires for power, ground, and signal, allowing for more stable voltage output and better noise immunity in industrial environments. The basic working principle hinges on converting physical parameters into electrical signals, where 2-wire sensors use current loops (typically 4-20 mA) while 3-wire sensors employ voltage signals for precise and reliable measurement.

Understanding 2-Wire Sensor Configuration

2-wire sensor configuration combines power supply and signal output in a single pair of wires, simplifying installation and reducing cost in applications like temperature and pressure sensing. These sensors rely on loop-powered designs where the sensor's resistance varies with the measured parameter, modulating the current flowing through the circuit typically between 4-20 mA for industrial standards. In contrast to 3-wire sensors that use separate power and signal lines, 2-wire sensors offer improved reliability in harsh environments by minimizing wiring complexity and potential points of failure.

Exploring 3-Wire Sensor Configuration

A 3-wire sensor configuration typically includes a power supply, ground, and output signal wire, offering improved stability and accuracy over 2-wire sensors by isolating the signal from the power source. You benefit from reduced electrical noise interference and enhanced signal integrity, which is critical for precise measurement applications in industrial automation. The additional wire in 3-wire sensors allows for more reliable data transmission, making them suitable for environments with fluctuating power conditions or longer cable runs.

Key Differences Between 2-Wire and 3-Wire Sensors

2-wire sensors use two wires for both power and signal transmission, typically operating on a loop-powered system, which simplifies wiring and reduces installation costs but limits signal strength and distance. 3-wire sensors separate power and signal lines, enhancing signal stability, enabling higher output currents, and supporting longer cable runs, making them suitable for complex industrial applications. Key differences include wiring complexity, signal reliability, and compatibility with power supply systems, where 3-wire sensors generally offer improved performance but increased installation complexity compared to 2-wire sensors.

Advantages of 2-Wire Sensors

2-wire sensors offer significant advantages in simplicity and cost-effectiveness by requiring only two connections for power and signal transmission, reducing wiring complexity and installation time. Their design enables easier integration into control systems and minimizes potential points of failure due to fewer components. These sensors are particularly beneficial in environments where space constraints and maintenance efficiency are critical.

Advantages of 3-Wire Sensors

3-wire sensors offer improved signal integrity and noise immunity compared to 2-wire sensors, making them suitable for more precise and reliable measurements in industrial applications. They provide separate power and output lines, enabling continuous sensor operation without voltage drop issues common in 2-wire configurations. This design supports higher accuracy and faster response times, essential for automated control systems.

Typical Applications of 2-Wire Sensors

2-wire sensors are commonly used in industrial automation for monitoring temperature, pressure, and proximity due to their simplified wiring and cost-effectiveness. Typical applications include process control systems, HVAC equipment, and basic presence detection where minimal wiring infrastructure is beneficial. Your choice of a 2-wire sensor ensures easier installation and maintenance in environments with limited power availability.

Typical Applications of 3-Wire Sensors

3-wire sensors are commonly used in industrial automation for precise position, speed, and proximity detection, especially within manufacturing assembly lines and robotics. Their design allows for separate power, ground, and signal wiring, enabling more stable signal transmission and reducing electrical noise interference compared to 2-wire sensors. Typical applications include conveyor systems, machine tool monitoring, and automated packaging, where reliable sensor output and faster response times are essential.

Choosing the Right Sensor: 2-Wire vs 3-Wire

Choosing the right sensor depends on the application's power and wiring requirements, with 2-wire sensors offering simplicity by combining power and signal in a single pair, ideal for low-power, long-distance installations. In contrast, 3-wire sensors separate power and signal lines, enhancing stability and reducing electrical noise, making them suitable for high-speed or precision measurements. Evaluating power availability, environmental conditions, and signal integrity requirements is crucial to selecting between 2-wire and 3-wire sensor configurations.

2-wire Sensor vs 3-wire Sensor Infographic

libmatt.com

libmatt.com