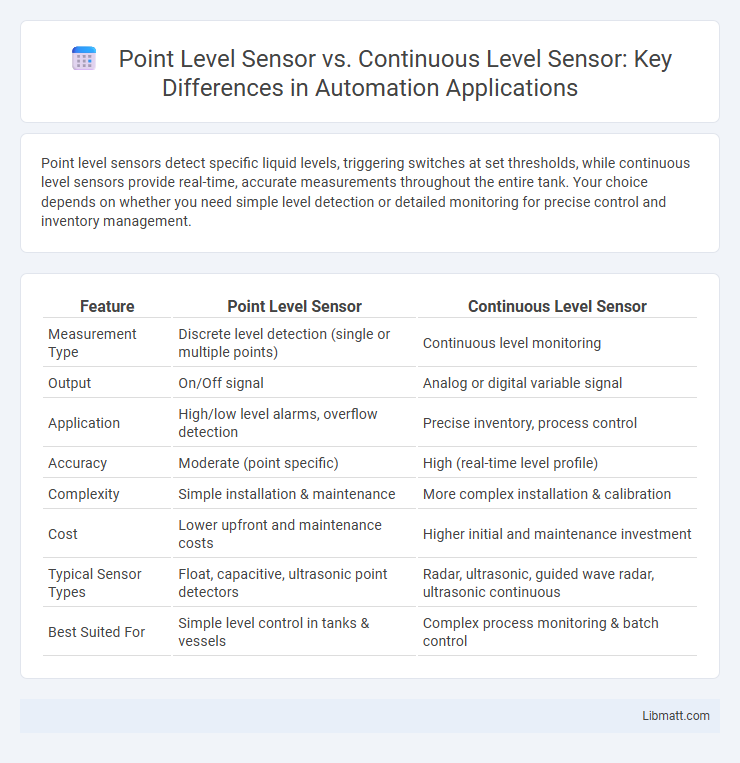

Point level sensors detect specific liquid levels, triggering switches at set thresholds, while continuous level sensors provide real-time, accurate measurements throughout the entire tank. Your choice depends on whether you need simple level detection or detailed monitoring for precise control and inventory management.

Table of Comparison

| Feature | Point Level Sensor | Continuous Level Sensor |

|---|---|---|

| Measurement Type | Discrete level detection (single or multiple points) | Continuous level monitoring |

| Output | On/Off signal | Analog or digital variable signal |

| Application | High/low level alarms, overflow detection | Precise inventory, process control |

| Accuracy | Moderate (point specific) | High (real-time level profile) |

| Complexity | Simple installation & maintenance | More complex installation & calibration |

| Cost | Lower upfront and maintenance costs | Higher initial and maintenance investment |

| Typical Sensor Types | Float, capacitive, ultrasonic point detectors | Radar, ultrasonic, guided wave radar, ultrasonic continuous |

| Best Suited For | Simple level control in tanks & vessels | Complex process monitoring & batch control |

Introduction to Level Sensors

Point level sensors detect specific liquid or solid levels, triggering alarms or controls at set thresholds, making them ideal for simple on/off applications. Continuous level sensors provide real-time measurement of the entire substance level within tanks or silos, offering precise control and monitoring. Your choice depends on whether you require binary detection or detailed level profiling for process optimization.

Overview of Point Level Sensors

Point level sensors detect specific liquid or solid levels within a container by triggering an alarm or controlling equipment when the material reaches a predefined height. These sensors are ideal for simple on/off level monitoring, providing reliable alerts for high or low levels without continuous data output. Your application benefits from cost-effective and maintenance-friendly solutions when precise level detection at critical points is required.

Overview of Continuous Level Sensors

Continuous level sensors provide real-time monitoring of liquid or solid materials within tanks or containers, offering precise measurement throughout the entire level range. These sensors use technologies such as ultrasonic, radar, or capacitance to deliver accurate, uninterrupted data critical for process control and inventory management. Unlike point level sensors that detect specific levels, continuous sensors enable dynamic adjustments by continuously tracking the exact level, improving operational efficiency and safety.

Key Differences Between Point and Continuous Level Sensors

Point level sensors detect liquid or solid presence at specific locations, offering on/off signals for high or low level alarms, while continuous level sensors provide real-time, accurate measurement of fluid levels over an entire range. Continuous sensors utilize technologies like ultrasonic, radar, or guided wave radar to deliver precise level profiling, whereas point sensors commonly use float, capacitive, or optical methods for discrete detection. Choosing between these depends on your need for either simple threshold detection or detailed level monitoring for process control.

Applications of Point Level Sensors

Point level sensors are ideal for applications requiring detection of specific liquid or solid levels, such as overflow prevention, dry run protection, and high/low alarm activation in tanks and silos. Common industries using point level sensors include water treatment, chemical processing, and food and beverage manufacturing, where precise level detection is critical for operational safety. Your system benefits from these sensors' simplicity and reliability in detecting preset levels without continuous monitoring.

Applications of Continuous Level Sensors

Continuous level sensors are widely used in industries such as water treatment, chemical processing, and oil and gas for precise monitoring of fluid levels. These sensors enable real-time data collection for inventory management, process control, and safety assurance in tanks, silos, and pipelines. Their ability to provide accurate, uninterrupted measurement makes them essential for applications requiring detailed level analysis and automation.

Advantages and Limitations of Point Level Sensors

Point level sensors offer a cost-effective and simple solution for detecting specific liquid or solid levels, providing reliable on/off signals crucial for overflow or empty tank alarms. Their limitations include inability to measure exact volume continuously, making them unsuitable for processes requiring detailed level monitoring. You can optimize system safety and operational efficiency by choosing point level sensors when precise level data is unnecessary.

Advantages and Limitations of Continuous Level Sensors

Continuous level sensors provide real-time, precise measurement of liquid or solid levels, enabling accurate monitoring and control in industrial processes, which enhances operational efficiency and safety. These sensors can detect varying levels within a tank or vessel, offering detailed data for inventory management and process automation. Limitations include higher cost, complexity of installation and maintenance, and potential sensitivity to environmental factors such as temperature, pressure, and fluid composition that may affect accuracy.

Choosing the Right Level Sensor for Your Needs

Point level sensors offer precise detection at specific set points, ideal for alarms and control in tanks and silos, while continuous level sensors provide real-time, accurate measurements across the entire liquid or solid level range. Selecting the right level sensor depends on application requirements such as tank size, media type, accuracy needs, and budget constraints. Consider factors including sensor material compatibility, installation environment, and maintenance demands to ensure optimal performance and reliability.

Conclusion: Point vs Continuous Level Sensors

Point level sensors detect specific fluid levels with on/off signals, offering simple and cost-effective solutions for applications requiring basic level detection. Continuous level sensors provide real-time measurements across the entire tank, enabling precise monitoring and control in processes demanding accurate fluid management. Your choice depends on whether you need discrete alerts or detailed level information for optimal system performance.

Point Level Sensor vs Continuous Level Sensor Infographic

libmatt.com

libmatt.com