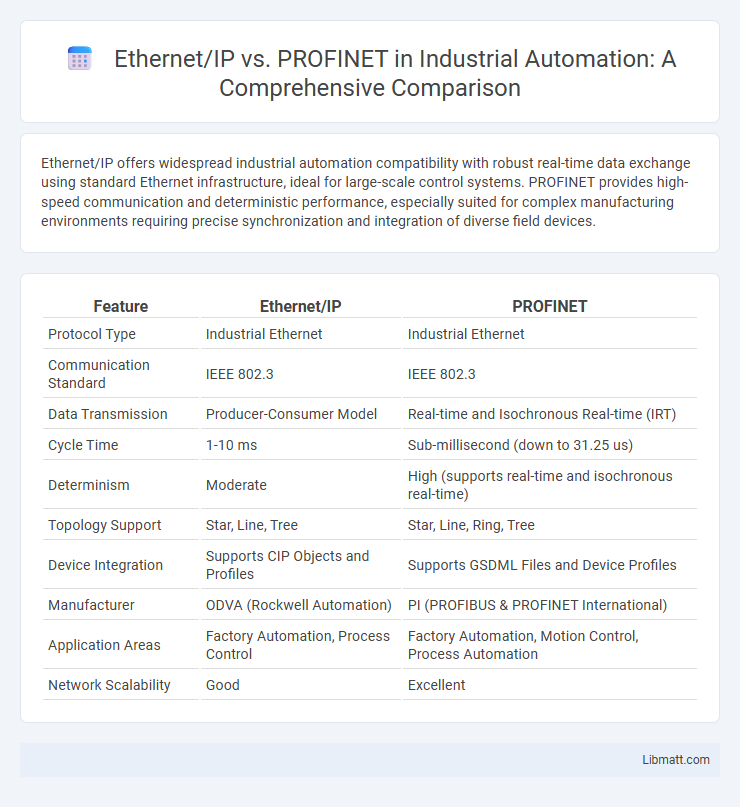

Ethernet/IP offers widespread industrial automation compatibility with robust real-time data exchange using standard Ethernet infrastructure, ideal for large-scale control systems. PROFINET provides high-speed communication and deterministic performance, especially suited for complex manufacturing environments requiring precise synchronization and integration of diverse field devices.

Table of Comparison

| Feature | Ethernet/IP | PROFINET |

|---|---|---|

| Protocol Type | Industrial Ethernet | Industrial Ethernet |

| Communication Standard | IEEE 802.3 | IEEE 802.3 |

| Data Transmission | Producer-Consumer Model | Real-time and Isochronous Real-time (IRT) |

| Cycle Time | 1-10 ms | Sub-millisecond (down to 31.25 us) |

| Determinism | Moderate | High (supports real-time and isochronous real-time) |

| Topology Support | Star, Line, Tree | Star, Line, Ring, Tree |

| Device Integration | Supports CIP Objects and Profiles | Supports GSDML Files and Device Profiles |

| Manufacturer | ODVA (Rockwell Automation) | PI (PROFIBUS & PROFINET International) |

| Application Areas | Factory Automation, Process Control | Factory Automation, Motion Control, Process Automation |

| Network Scalability | Good | Excellent |

Introduction to Ethernet/IP and PROFINET

Ethernet/IP is an industrial networking protocol that uses standard Ethernet technology combined with the Common Industrial Protocol (CIP) for real-time communication in automation systems. PROFINET is an open industrial Ethernet standard designed for data exchange between controllers and devices, emphasizing real-time performance and interoperability in factory automation. Understanding the differences between Ethernet/IP and PROFINET helps you choose the best network protocol tailored to your industrial automation needs.

Overview of Industrial Ethernet Protocols

Ethernet/IP and PROFINET are leading Industrial Ethernet protocols designed for real-time communication in automation systems. Ethernet/IP utilizes the Common Industrial Protocol (CIP) over standard Ethernet, enabling seamless integration with enterprise networks and device interoperability. PROFINET, developed by PROFIBUS & PROFINET International, offers deterministic real-time data exchange and extensive support for diagnostics, making it ideal for complex manufacturing environments requiring high-speed and reliable communication.

Architecture and Communication Models

Ethernet/IP uses a producer-consumer architecture with explicit and implicit messaging to support real-time data exchange, relying on the Common Industrial Protocol (CIP) for layered communication. PROFINET employs a client-server and real-time communication model, featuring cyclic data exchange and prioritized real-time frames (RT and IRT) to ensure deterministic performance. Your choice between these protocols depends on the required network architecture flexibility and the criticality of timing in communication.

Performance and Speed Comparison

Ethernet/IP offers data transfer rates up to 1 Gbps, supporting deterministic communication through CIP Sync and Time-Sensitive Networking (TSN) for enhanced performance in industrial automation. PROFINET provides comparable speeds ranging from 100 Mbps to 1 Gbps, with real-time capabilities achieved via Isochronous Real-Time (IRT) technology, enabling cycle times as low as 31.25 microseconds for time-critical applications. Both protocols deliver high-speed communication, but PROFINET's IRT feature often results in superior real-time performance for applications requiring ultra-low latency and precise synchronization.

Scalability and Network Topologies

Ethernet/IP offers high scalability with flexible star, line, and tree network topologies, ideal for large industrial systems requiring real-time data exchange. PROFINET supports various topologies such as line, star, ring, and tree, with built-in redundancy for enhanced reliability in complex automation networks. Your choice depends on the scalability needs and network design preferences for seamless integration and performance.

Integration with Industrial Automation Systems

Ethernet/IP and PROFINET are both widely adopted industrial Ethernet protocols designed for seamless integration with industrial automation systems, but they differ in their communication standards and device compatibility. Ethernet/IP leverages the Common Industrial Protocol (CIP) and is highly compatible with Rockwell Automation products, making it ideal for systems already using this ecosystem. PROFINET, based on the IEC 61158 standard, offers real-time data exchange optimized for Siemens and other automation devices, providing flexibility and scalability in industrial network integration.

Security Features and Considerations

Ethernet/IP employs CIP Security standards with encryption, authentication, and integrity checks to safeguard industrial communications, making it suitable for protecting critical data in automated environments. PROFINET integrates advanced security measures such as VPN support, device authentication, and Real-Time Ethernet (RTE) protection, prioritizing secure, real-time data exchange within industrial networks. Your choice between Ethernet/IP and PROFINET should consider each protocol's security capabilities relative to your network's vulnerability requirements and risk management strategy.

Compatibility and Interoperability

Ethernet/IP offers broad compatibility with devices using the Common Industrial Protocol (CIP), enabling seamless integration in networks primarily based on Rockwell Automation and ODVA standards. PROFINET provides strong interoperability across Siemens and other industrial equipment, supporting real-time communication with Devices Profile for Web Services (DPWS). Understanding your system's existing infrastructure helps determine which protocol ensures optimal compatibility and interoperability for your industrial automation needs.

Industry Applications and Use Cases

Ethernet/IP is widely adopted in manufacturing automation and process control due to its robustness in handling complex real-time data exchanges across industrial equipment and robotics. PROFINET excels in factory automation and motion control applications, offering superior synchronization and integration with Siemens PLCs and other automation devices. Choosing between Ethernet/IP and PROFINET depends on your specific industry requirements, such as the need for interoperability, speed, and device compatibility in your automation system.

Future Trends and Developments

Ethernet/IP and PROFINET are both advancing with the integration of IEEE Time-Sensitive Networking (TSN) standards to enhance real-time communication and deterministic performance in Industrial IoT environments. PROFINET is increasingly adopting AI-driven diagnostics and edge computing capabilities to optimize automation processes, while Ethernet/IP focuses on expanding interoperability with existing Ethernet-based systems and cloud integration. Your choice between the two should consider future-proofing needs such as scalability, latency requirements, and seamless integration with Industry 4.0 technologies.

Ethernet/IP vs PROFINET Infographic

libmatt.com

libmatt.com