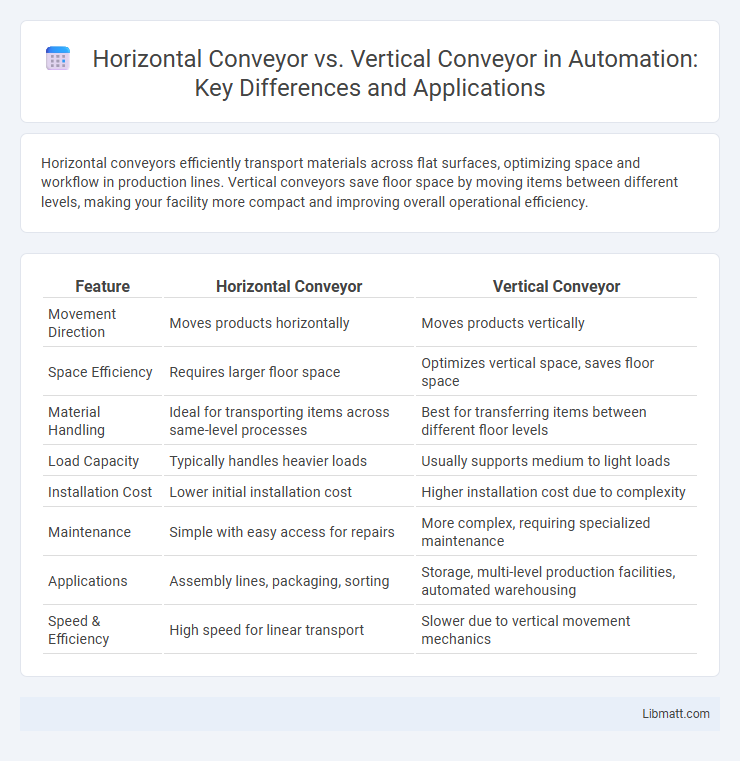

Horizontal conveyors efficiently transport materials across flat surfaces, optimizing space and workflow in production lines. Vertical conveyors save floor space by moving items between different levels, making your facility more compact and improving overall operational efficiency.

Table of Comparison

| Feature | Horizontal Conveyor | Vertical Conveyor |

|---|---|---|

| Movement Direction | Moves products horizontally | Moves products vertically |

| Space Efficiency | Requires larger floor space | Optimizes vertical space, saves floor space |

| Material Handling | Ideal for transporting items across same-level processes | Best for transferring items between different floor levels |

| Load Capacity | Typically handles heavier loads | Usually supports medium to light loads |

| Installation Cost | Lower initial installation cost | Higher installation cost due to complexity |

| Maintenance | Simple with easy access for repairs | More complex, requiring specialized maintenance |

| Applications | Assembly lines, packaging, sorting | Storage, multi-level production facilities, automated warehousing |

| Speed & Efficiency | High speed for linear transport | Slower due to vertical movement mechanics |

Introduction to Conveyor Systems

Conveyor systems play a crucial role in material handling, with horizontal conveyors designed to move items across flat surfaces efficiently, while vertical conveyors transport goods between different elevation levels. Horizontal conveyors optimize your production line by enabling smooth and continuous flow of materials, whereas vertical conveyors save valuable floor space by integrating vertical movement within compact areas. Choosing between horizontal and vertical conveyors depends on your facility layout, load requirements, and workflow complexity.

Overview of Horizontal Conveyors

Horizontal conveyors transport materials or products in a straight, level path, typically used for moving items across factory floors or between processes. They excel in handling high volumes with consistent speed, reducing manual labor and increasing efficiency in assembly lines or packaging systems. Common types include belt conveyors, roller conveyors, and chain conveyors, each optimized for different load types and operational environments.

Overview of Vertical Conveyors

Vertical conveyors efficiently transport materials between different floor levels, optimizing space in warehouses and manufacturing plants. They utilize belts, chains, or lifts to move products vertically, supporting continuous and automated workflow. Your facility can benefit from their ability to handle heavy loads while minimizing footprint compared to traditional inclined conveyors.

Key Differences Between Horizontal and Vertical Conveyors

Horizontal conveyors primarily move materials in a straight, level line, optimizing space for transporting heavy or bulky items efficiently across floors. Vertical conveyors elevate or lower goods between different heights, saving floor space and enabling seamless multi-level operations. Your choice depends on whether your operation prioritizes horizontal distance coverage or vertical space utilization for material handling.

Space Utilization and Facility Layout

Horizontal conveyors optimize space by allowing smooth, linear movement of goods across expansive floor layouts, ideal for facilities with ample horizontal space. Vertical conveyors maximize vertical space utilization by efficiently transporting items between different levels without expanding the facility's footprint, making them crucial in multi-story warehouses. Integrating both types can enhance overall facility layout by balancing floor space constraints with vertical elevation needs, promoting efficient material flow and optimized storage capacity.

Throughput and Efficiency Comparison

Horizontal conveyors typically offer higher throughput due to their straightforward, linear design that enables continuous, fast transport of materials over longer distances with minimal interruptions. Vertical conveyors, while essential for saving floor space and moving items efficiently between different elevations, usually have lower throughput rates because of slower vertical lifting mechanisms and capacity limitations. Efficiency in horizontal conveyors is maximized by smooth, uninterrupted flow, whereas vertical conveyors optimize efficiency through compact design and energy-saving lift technologies tailored for vertical transport.

Application Suitability: When to Use Each Conveyor

Horizontal conveyors are ideal for transporting goods across long distances on a single plane, making them suitable for assembly lines, packaging, and material handling in warehouses. Vertical conveyors excel in moving products between different elevations within limited floor space, commonly used in multi-level manufacturing plants, storage facilities, and automated picking systems. Choosing between horizontal and vertical conveyors depends on the spatial layout, product dimensions, and workflow requirements to optimize efficiency and reduce manual labor.

Cost Considerations and ROI

Horizontal conveyors typically have lower initial costs and simpler installation compared to vertical conveyors, making them more budget-friendly for straightforward material handling tasks. Vertical conveyors often require higher upfront investment due to complex mechanisms and space-saving designs but offer better ROI in facilities with limited floor space by optimizing vertical storage and reducing manual handling. Evaluating total cost of ownership and throughput efficiency is crucial to determine the most cost-effective conveyor type for specific operational needs.

Maintenance and Safety Factors

Horizontal conveyors typically require less frequent maintenance due to simpler mechanical components and easier access for inspections and repairs. Vertical conveyors demand rigorous safety protocols because of elevated risks such as falling hazards and mechanical malfunctions at height, necessitating specialized safety features like guardrails and emergency stop systems. Understanding these maintenance and safety distinctions ensures your conveyor system operates efficiently while protecting workers effectively.

Choosing the Right Conveyor for Your Needs

Selecting the right conveyor depends on your facility's space and product flow requirements; horizontal conveyors excel in transporting items across long distances on a single level, while vertical conveyors efficiently move products between floors or elevations. Assess your workflow, product dimensions, and handling frequency to determine whether a horizontal conveyor's simplicity or a vertical conveyor's space-saving design better suits your operations. Optimizing your conveyor choice can enhance productivity and streamline material handling processes effectively.

Horizontal Conveyor vs Vertical Conveyor Infographic

libmatt.com

libmatt.com