MCC panels (Motor Control Centers) are designed to control multiple electric motors and provide centralized motor management, while PCC panels (Power Control Centers) focus on distributing and controlling electrical power across various loads in industrial settings. Choosing between MCC and PCC panels depends on your facility's specific control and power distribution requirements to optimize operational efficiency.

Table of Comparison

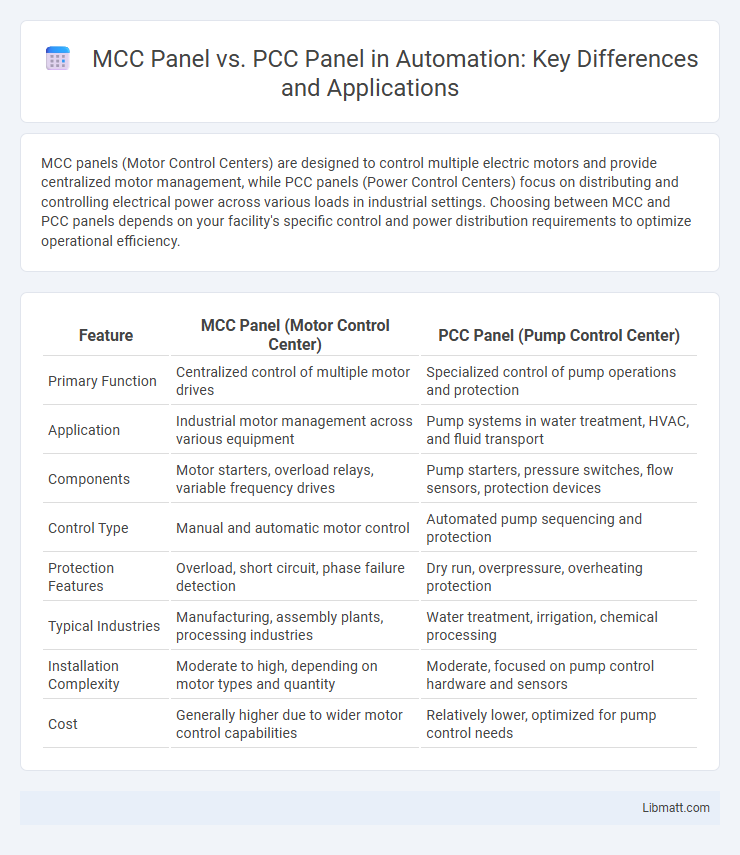

| Feature | MCC Panel (Motor Control Center) | PCC Panel (Pump Control Center) |

|---|---|---|

| Primary Function | Centralized control of multiple motor drives | Specialized control of pump operations and protection |

| Application | Industrial motor management across various equipment | Pump systems in water treatment, HVAC, and fluid transport |

| Components | Motor starters, overload relays, variable frequency drives | Pump starters, pressure switches, flow sensors, protection devices |

| Control Type | Manual and automatic motor control | Automated pump sequencing and protection |

| Protection Features | Overload, short circuit, phase failure detection | Dry run, overpressure, overheating protection |

| Typical Industries | Manufacturing, assembly plants, processing industries | Water treatment, irrigation, chemical processing |

| Installation Complexity | Moderate to high, depending on motor types and quantity | Moderate, focused on pump control hardware and sensors |

| Cost | Generally higher due to wider motor control capabilities | Relatively lower, optimized for pump control needs |

Introduction to MCC and PCC Panels

MCC (Motor Control Center) panels are centralized assemblies that house motor controllers and facilitate the control and monitoring of electric motors in industrial environments. PCC (Power Control Center) panels focus on distributing and controlling power to multiple electrical loads, including motors, transformers, and lighting systems, providing a broader power management solution. Both MCC and PCC panels integrate protective devices, control units, and communication modules to enhance operational efficiency and safety in electrical distribution systems.

Definition and Purpose of MCC Panels

MCC Panels, or Motor Control Centers, are centralized units designed to control and manage multiple electric motors in industrial settings, enhancing operational efficiency and safety. They house motor controllers, circuit breakers, and overload relays, providing streamlined motor protection and easy system maintenance. Your choice of an MCC Panel ensures organized motor management, reducing downtime and improving overall plant performance.

Definition and Purpose of PCC Panels

PCC panels, or Power Control Centers, are centralized systems designed to distribute and control electrical power in industrial and commercial settings. They manage multiple motor control centers (MCC) and ensure synchronized operation, enhanced protection, and efficient power distribution across complex electrical networks. PCC panels improve system reliability by integrating control, monitoring, and fault detection functions for various electrical loads.

Key Components of MCC Panels

MCC panels typically consist of motor starters, circuit breakers, contactors, overload relays, and control transformers designed to centralize motor control and protection within industrial environments. These key components enable MCC panels to monitor, control, and protect multiple motors efficiently while providing easy maintenance access. In contrast, PCC panels focus on power distribution and often include busbars, circuit breakers, metering devices, and protection relays rather than motor-specific control elements.

Key Components of PCC Panels

PCC Panels, or Power Control Centers, primarily include key components such as circuit breakers, control relays, contactors, transformers, and overload relays, designed to manage and distribute electrical power efficiently. These panels often feature motor starters and programmable logic controllers (PLCs) to ensure precise motor operation and system automation. Unlike MCC Panels, PCC Panels focus on centralized control for multiple motors and power circuits within industrial environments.

Differences Between MCC and PCC Panels

MCC (Motor Control Center) panels primarily manage multiple motor control units, centralizing the control of electric motors in industrial environments, while PCC (Power Control Center) panels focus on distributing and controlling electrical power across various loads. MCC panels are designed for controlling motor starters, overload protection, and monitoring motor statuses, whereas PCC panels handle power distribution, circuit protection, and load management for the entire electrical system. Understanding these differences helps you choose the right panel for efficiently managing motors or overall power distribution in your facility.

Common Applications of MCC Panels

MCC Panels (Motor Control Centers) are widely used in industrial environments such as manufacturing plants, water treatment facilities, and HVAC systems to control and monitor multiple electric motors from a centralized location. These panels provide efficient motor management, protection, and ease of maintenance, making them ideal for complex applications requiring coordinated motor control. Your facility can benefit from MCC Panels by enhancing operational reliability and reducing downtime in multi-motor setups.

Common Applications of PCC Panels

PCC panels are primarily used in industrial environments for controlling multiple motor drives and providing centralized automation in manufacturing plants, water treatment facilities, and HVAC systems. These panels integrate motor starters, control switches, and instrumentation to facilitate precise control and monitoring of complex processes. Their design supports enhanced motor protection and efficient energy management, making them essential in process industries and large commercial buildings.

Advantages and Disadvantages of MCC vs PCC Panels

MCC (Motor Control Center) panels offer centralized control, easy maintenance, and scalability for multiple motor applications, making them ideal for industrial environments requiring robust motor management. PCC (Power Control Center) panels provide centralized control of power distribution with advanced protection features and better fault isolation, which suits applications demanding high power handling and enhanced safety. MCC panels may have limitations in power distribution flexibility and fault handling compared to PCC panels, while PCC panels typically involve higher costs and complexity in installation and maintenance.

Choosing the Right Panel for Your Industrial Needs

MCC panels are designed for controlling multiple motors individually, making them ideal for industries requiring precise motor management and monitoring. PCC panels offer centralized control over various electrical circuits and equipment, suitable for operations demanding integrated power distribution and automation. Assess your industrial needs for motor control granularity versus comprehensive power management to choose the right panel for your facility.

MCC Panel vs PCC Panel Infographic

libmatt.com

libmatt.com