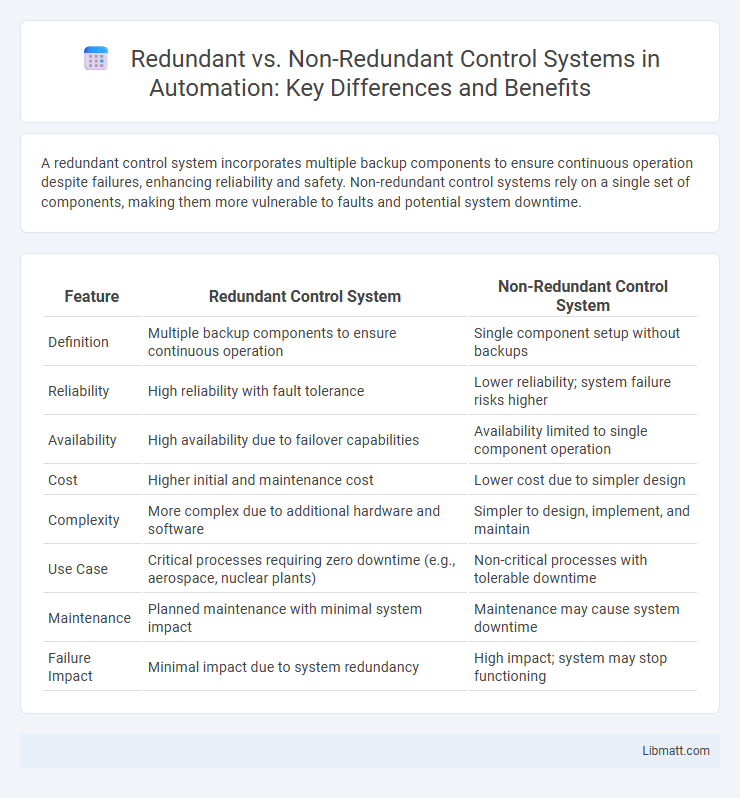

A redundant control system incorporates multiple backup components to ensure continuous operation despite failures, enhancing reliability and safety. Non-redundant control systems rely on a single set of components, making them more vulnerable to faults and potential system downtime.

Table of Comparison

| Feature | Redundant Control System | Non-Redundant Control System |

|---|---|---|

| Definition | Multiple backup components to ensure continuous operation | Single component setup without backups |

| Reliability | High reliability with fault tolerance | Lower reliability; system failure risks higher |

| Availability | High availability due to failover capabilities | Availability limited to single component operation |

| Cost | Higher initial and maintenance cost | Lower cost due to simpler design |

| Complexity | More complex due to additional hardware and software | Simpler to design, implement, and maintain |

| Use Case | Critical processes requiring zero downtime (e.g., aerospace, nuclear plants) | Non-critical processes with tolerable downtime |

| Maintenance | Planned maintenance with minimal system impact | Maintenance may cause system downtime |

| Failure Impact | Minimal impact due to system redundancy | High impact; system may stop functioning |

Introduction to Control Systems

Control systems regulate the behavior of dynamic processes, ensuring stability, accuracy, and desired performance by managing inputs and outputs. Redundant control systems incorporate multiple controllers or components to enhance reliability and fault tolerance, whereas non-redundant systems rely on a single controller, making them more vulnerable to failures. Key applications in aerospace, industrial automation, and power grids highlight the importance of choosing between redundant and non-redundant architectures based on system criticality and risk tolerance.

Defining Redundant Control Systems

Redundant control systems consist of multiple independent controllers operating in parallel to ensure continuous system functionality in case one controller fails. These systems enhance reliability and safety by automatically switching to backup controllers without interrupting the process. Non-redundant control systems rely on a single controller, which increases vulnerability to failures and potential downtime.

Understanding Non-Redundant Control Systems

Non-redundant control systems rely on a single control unit to manage processes, making them simpler but more vulnerable to failure. These systems are often used in applications where cost and complexity must be minimized, but they lack backup support in case of a malfunction. Understanding the limitations of non-redundant control systems is crucial for assessing risk and determining when redundancy is necessary for maintaining system reliability.

Key Differences Between Redundant and Non-Redundant Systems

Redundant control systems feature multiple backup components to ensure continuous operation during failures, enhancing reliability and safety in critical applications. Non-redundant systems rely on a single control channel, which can lead to system downtime if a failure occurs. Key differences include fault tolerance, system complexity, and cost, with redundant systems typically being more complex and expensive but offering higher availability and risk mitigation.

Advantages of Redundant Control Systems

Redundant control systems enhance operational reliability by providing backup components that immediately take over if the primary system fails, minimizing downtime and ensuring continuous process control. These systems improve safety in critical applications such as aerospace, nuclear power, and industrial automation by reducing the risk of catastrophic failures. Incorporating redundancy also facilitates easier maintenance and system upgrades without halting operations, thereby increasing overall system availability and efficiency.

Drawbacks of Redundant Control Architectures

Redundant control architectures increase system complexity, leading to higher implementation and maintenance costs due to additional hardware and software components. They can cause synchronization challenges, where inconsistent data between redundant controllers may result in delayed or incorrect decision-making. Furthermore, increased system size and complexity often elevate the risk of cascading failures and make fault diagnosis more difficult.

Benefits and Limitations of Non-Redundant Systems

Non-redundant control systems offer cost-effective solutions with simpler design and easier maintenance, making them suitable for less critical applications where downtime is acceptable. These systems, however, lack backup components, leading to potential total failure during faults and resulting in reduced reliability and higher risk of operational interruptions. Non-redundant systems are generally more vulnerable to single points of failure, limiting their use in safety-critical industries where continuous operation is essential.

Typical Applications for Each Control System Type

Redundant control systems are typically employed in critical infrastructure such as aerospace, nuclear power plants, and medical devices where system failure can lead to catastrophic consequences, ensuring high reliability and fault tolerance. Non-redundant control systems are commonly found in less critical applications like household appliances and small manufacturing processes where cost-effectiveness and simplicity are prioritized. Your choice between these systems should align with the required reliability and risk management of the specific application.

Choosing the Right Control System for Your Needs

Choosing the right control system depends on the criticality of your application and the need for reliability. Redundant control systems offer enhanced fault tolerance by duplicating key components, minimizing downtime and ensuring continuous operation in industries like aerospace or healthcare. Non-redundant control systems provide a cost-effective solution for less critical processes where occasional interruptions are acceptable, making it important to assess your system's operational requirements before deciding.

Future Trends in Control System Design

Future trends in control system design emphasize increased integration of AI-driven predictive analytics and adaptive algorithms to enhance system resilience and efficiency. Redundant control systems evolve with decentralized architectures and edge computing, improving fault tolerance and real-time responsiveness. Non-redundant designs focus on optimized sensor fusion and machine learning models to reduce hardware costs while maintaining high reliability through advanced diagnostics.

Redundant vs Non-Redundant Control System Infographic

libmatt.com

libmatt.com