Pneumatic relays use air pressure to control the switching of circuits, offering high reliability in harsh environments with no electrical interference, while electronic relays rely on solid-state components for faster response times and greater precision. Your choice depends on the application requirements, with pneumatic relays favored for heavy-duty industrial use and electronic relays preferred for compact, sensitive electronic control systems.

Table of Comparison

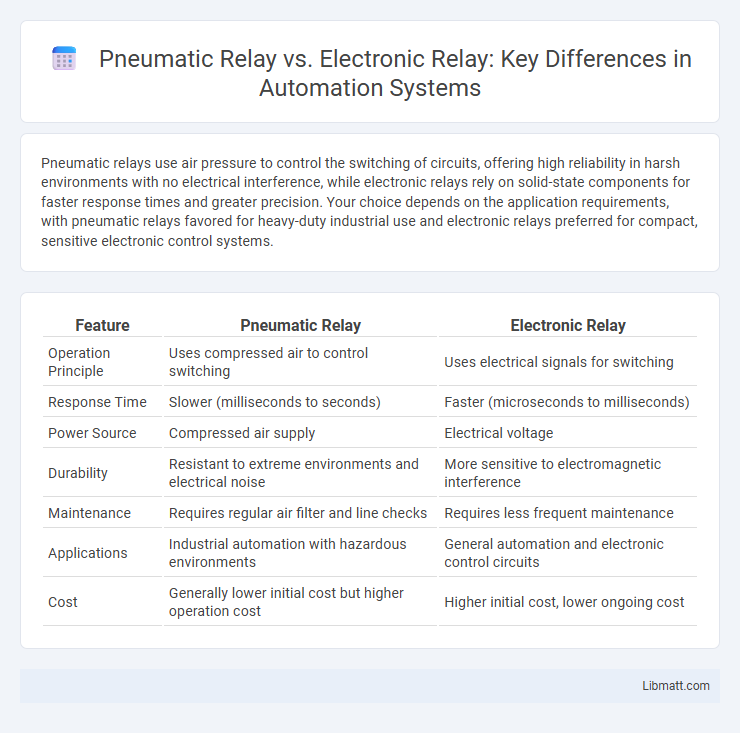

| Feature | Pneumatic Relay | Electronic Relay |

|---|---|---|

| Operation Principle | Uses compressed air to control switching | Uses electrical signals for switching |

| Response Time | Slower (milliseconds to seconds) | Faster (microseconds to milliseconds) |

| Power Source | Compressed air supply | Electrical voltage |

| Durability | Resistant to extreme environments and electrical noise | More sensitive to electromagnetic interference |

| Maintenance | Requires regular air filter and line checks | Requires less frequent maintenance |

| Applications | Industrial automation with hazardous environments | General automation and electronic control circuits |

| Cost | Generally lower initial cost but higher operation cost | Higher initial cost, lower ongoing cost |

Introduction to Pneumatic and Electronic Relays

Pneumatic relays use compressed air to mechanically control valve operation in industrial automation, offering reliable performance in harsh environments with minimal electrical interference. Electronic relays employ electrical signals to switch circuits and control devices, providing faster response times and greater precision for complex control systems. Understanding the differences in operation and application can help you select the appropriate relay for your automation needs.

Basic Principles of Operation

Pneumatic relays operate by using compressed air to transmit signals and control mechanical movement, relying on pressure differences to activate or deactivate valves. Electronic relays function through electrical input signals that energize an internal coil, causing a magnetic field to mechanically switch contacts and control circuits. Pneumatic systems excel in environments requiring explosion-proof components, while electronic relays offer faster response times and higher precision in signal processing.

Key Components and Design Differences

Pneumatic relays rely on compressed air, mechanical diaphragms, and valves to control signal transmission, whereas electronic relays use semiconductor components, coils, and contacts to switch electrical circuits. The design of pneumatic relays emphasizes robustness in harsh environments with simple mechanical parts, while electronic relays prioritize fast switching speeds and precise control through integrated circuits. Key differences include pneumatic relays' slower response time and dependence on air pressure, contrasted with electronic relays' compact size and reliance on electrical input signals.

Performance and Response Time Comparison

Pneumatic relays typically exhibit slower response times due to reliance on air pressure changes, often ranging from 20 to 100 milliseconds, whereas electronic relays respond within microseconds to milliseconds, offering superior performance in high-speed applications. The precise and rapid switching capabilities of electronic relays make them ideal for scenarios demanding quick and accurate control, while pneumatic relays excel in environments where electrical interference resistance is critical. Your choice depends on the required speed and environmental constraints, with electronic relays favored for high-performance, fast-response systems.

Accuracy and Reliability Factors

Pneumatic relays offer high reliability in harsh environments due to their resistance to electrical interference and simple mechanical design but may exhibit lower accuracy because of air compressibility and response lag. Electronic relays provide superior accuracy with fast switching times and precise control, leveraging solid-state components that minimize response variability. Reliability in electronic relays depends on circuit quality and protection against voltage spikes, while pneumatic relays excel in durability under extreme temperatures and moisture conditions.

Installation and Maintenance Requirements

Pneumatic relays require careful installation involving precise tubing connections and air pressure calibration to ensure optimal performance, while electronic relays demand proper wiring and voltage compatibility checks. Maintenance for pneumatic relays involves regular inspection for air leaks and filter replacements, whereas electronic relays necessitate periodic testing for electrical continuity and potential component wear. Understanding these differences helps you choose the relay type best suited for your system's installation complexity and maintenance capabilities.

Environmental Suitability and Application Areas

Pneumatic relays excel in harsh environments such as explosive, wet, or dusty industrial settings due to their resistance to sparks and electrical interference, making them ideal for chemical plants and oil refineries. Electronic relays thrive in precision-controlled applications like automation systems and electronic devices, benefiting from faster response times and compact design but requiring clean, dry conditions. Your choice should factor in environmental suitability, with pneumatic relays favored for rugged conditions and electronic relays preferred for complex, low-voltage control circuits.

Cost Considerations and Long-Term Value

Pneumatic relays often have lower initial costs due to simpler components and ease of maintenance, making them suitable for applications with budget constraints. Electronic relays offer higher precision, faster response times, and greater energy efficiency, which can lead to reduced operational expenses and enhanced long-term value in automated systems. Evaluating your system's complexity and maintenance capabilities will help determine whether the upfront investment in electronic relays provides cost savings over the device lifespan.

Advantages and Limitations of Each Relay Type

Pneumatic relays offer advantages such as resistance to electrical interference, suitability for hazardous environments, and simplicity in maintenance, but are limited by slower response times and larger physical size. Electronic relays provide faster switching speeds, higher precision, and compact design, yet can be susceptible to electromagnetic interference and require stable power supply for optimal performance. Your choice between pneumatic and electronic relays should consider the specific application requirements, including environmental conditions and response speed.

Choosing the Right Relay for Your Application

Choosing the right relay for your application depends on factors such as response time, control signal type, and environmental conditions. Pneumatic relays excel in explosive or high-temperature environments due to their air-driven operation, while electronic relays offer faster switching speeds and precise control for complex circuits. Your decision should balance durability requirements with the need for speed and signal compatibility to optimize system performance.

Pneumatic Relay vs Electronic Relay Infographic

libmatt.com

libmatt.com