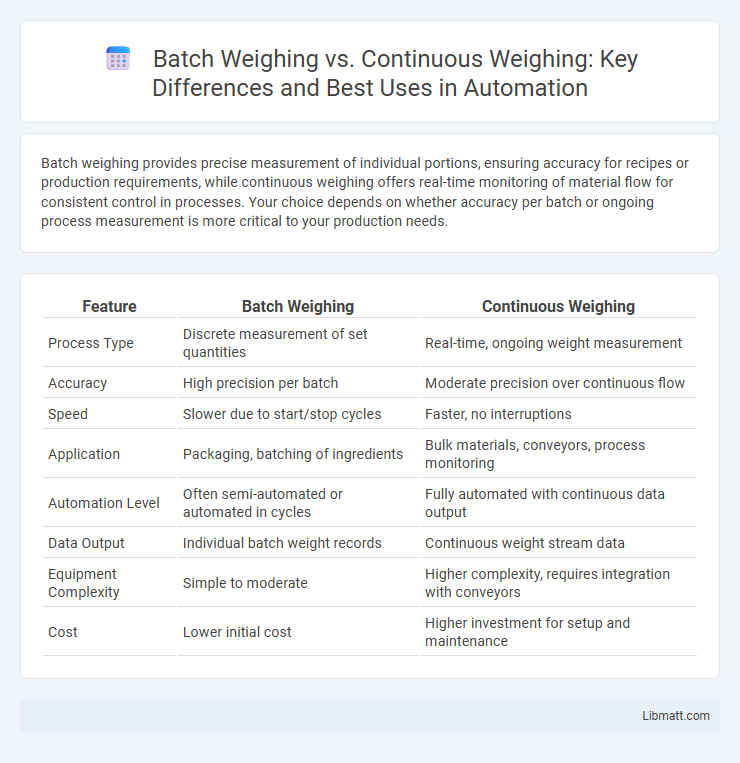

Batch weighing provides precise measurement of individual portions, ensuring accuracy for recipes or production requirements, while continuous weighing offers real-time monitoring of material flow for consistent control in processes. Your choice depends on whether accuracy per batch or ongoing process measurement is more critical to your production needs.

Table of Comparison

| Feature | Batch Weighing | Continuous Weighing |

|---|---|---|

| Process Type | Discrete measurement of set quantities | Real-time, ongoing weight measurement |

| Accuracy | High precision per batch | Moderate precision over continuous flow |

| Speed | Slower due to start/stop cycles | Faster, no interruptions |

| Application | Packaging, batching of ingredients | Bulk materials, conveyors, process monitoring |

| Automation Level | Often semi-automated or automated in cycles | Fully automated with continuous data output |

| Data Output | Individual batch weight records | Continuous weight stream data |

| Equipment Complexity | Simple to moderate | Higher complexity, requires integration with conveyors |

| Cost | Lower initial cost | Higher investment for setup and maintenance |

Introduction to Batch and Continuous Weighing

Batch weighing involves measuring discrete quantities of materials in separate, individual sets, ensuring precise control over each batch's weight, commonly used in manufacturing and food processing industries. Continuous weighing measures the weight of a material as it moves through a process in a steady stream, ideal for processes requiring real-time monitoring and high-speed production lines. Both methods optimize accuracy and efficiency depending on the specific application and production requirements.

Defining Batch Weighing Systems

Batch weighing systems measure specific quantities of materials in discrete amounts, ensuring precise control over each individual batch. These systems commonly use load cells or weighing sensors to capture accurate weight data before moving to the next batch. Your operations benefit from enhanced accuracy and reduced waste by implementing batch weighing for processes requiring exact portioning.

Understanding Continuous Weighing Systems

Continuous weighing systems provide real-time, on-the-fly measurement of material flow without interrupting the production process, making them ideal for high-speed, large-scale operations. These systems use load cells integrated into conveyors or chutes to continuously monitor weight and ensure precise dosing and material consistency. The accuracy and efficiency of continuous weighing enhance process control, reduce waste, and improve overall production quality compared to batch weighing methods.

Key Differences Between Batch and Continuous Weighing

Batch weighing measures discrete quantities of material in separate steps for precise portion control, while continuous weighing monitors the weight of materials in real-time during ongoing processes, ensuring constant flow accuracy. Batch weighing is ideal for applications requiring exact doses in manufacturing or packaging, whereas continuous weighing excels in processes like conveyor belt systems or fluid flow where uninterrupted measurement is critical. The main difference lies in the operation mode: batch weighing involves stop-start cycles, and continuous weighing provides ongoing, dynamic weight data.

Advantages of Batch Weighing

Batch weighing offers precise control over ingredient quantities, reducing waste and ensuring consistent product quality. It simplifies complex formulations by allowing individual component measurement before mixing, which enhances accuracy and traceability. Your production process benefits from flexibility, as batch weighing easily adapts to different product recipes and scales without extensive recalibration.

Benefits of Continuous Weighing

Continuous weighing offers precise, real-time measurement of material flow, enhancing process efficiency and product consistency in industries such as manufacturing and food processing. This method reduces material waste and downtime by allowing immediate adjustments, leading to improved productivity and cost savings. Integration with automated control systems enables seamless monitoring and data collection, supporting better decision-making and process optimization.

Comparing Accuracy and Precision

Batch weighing offers superior accuracy by measuring discrete portions, minimizing errors caused by material flow inconsistencies. Continuous weighing provides high precision through real-time monitoring, enabling consistent weight tracking during processing. Accuracy in batch weighing excels for fixed quantities, while continuous weighing ensures precision in variable throughput applications.

Application Areas for Each Weighing Method

Batch weighing is ideal for industries like food processing, pharmaceuticals, and chemical manufacturing where precise, incremental measurements of materials are critical for formulation accuracy. Continuous weighing suits applications such as bulk material handling, conveyor systems, and mining where real-time, uninterrupted weight monitoring enhances process efficiency and control. Your choice depends on whether your operation demands exact batch quantities or ongoing weight tracking to optimize production flow.

Factors to Consider When Choosing a Weighing System

Selecting the ideal weighing system depends on factors such as accuracy requirements, production speed, and material consistency. Batch weighing offers precise control for small to medium quantities, while continuous weighing excels in high-speed processes with constant flow rates. Your specific application demands, including maintenance capabilities and integration with existing equipment, play a crucial role in determining the most efficient option.

Conclusion: Selecting the Best Weighing Solution

Batch weighing offers precise measurement by processing materials in fixed quantities, ideal for applications requiring accuracy and control. Continuous weighing provides real-time data and efficiency in processes dealing with large volumes or continuous flow. Your choice depends on operational needs, prioritizing accuracy with batch systems or speed and monitoring with continuous solutions.

Batch Weighing vs Continuous Weighing Infographic

libmatt.com

libmatt.com