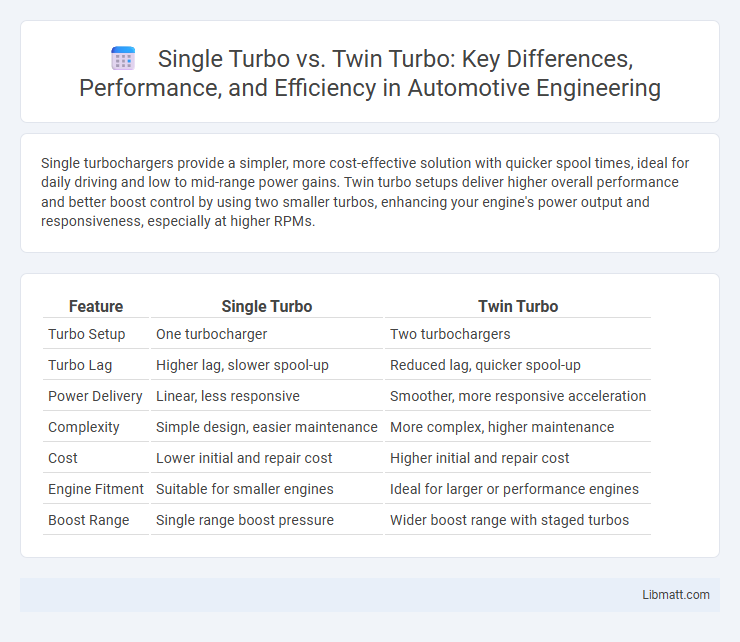

Single turbochargers provide a simpler, more cost-effective solution with quicker spool times, ideal for daily driving and low to mid-range power gains. Twin turbo setups deliver higher overall performance and better boost control by using two smaller turbos, enhancing your engine's power output and responsiveness, especially at higher RPMs.

Table of Comparison

| Feature | Single Turbo | Twin Turbo |

|---|---|---|

| Turbo Setup | One turbocharger | Two turbochargers |

| Turbo Lag | Higher lag, slower spool-up | Reduced lag, quicker spool-up |

| Power Delivery | Linear, less responsive | Smoother, more responsive acceleration |

| Complexity | Simple design, easier maintenance | More complex, higher maintenance |

| Cost | Lower initial and repair cost | Higher initial and repair cost |

| Engine Fitment | Suitable for smaller engines | Ideal for larger or performance engines |

| Boost Range | Single range boost pressure | Wider boost range with staged turbos |

Introduction to Turbocharging

Turbocharging enhances engine performance by forcing compressed air into the combustion chamber, increasing power output and efficiency. A single turbo system uses one turbocharger to boost the engine, suitable for simpler setups and reducing lag through optimized sizing. Twin turbo setups employ two smaller turbos, often improving responsiveness and power delivery across varying engine speeds by splitting exhaust gases between turbos.

What is a Single Turbo?

A Single Turbo is a turbocharger system that uses one turbo to compress air into the engine, enhancing power and efficiency by increasing air intake pressure. It offers simpler installation, lower cost, and less complexity compared to twin-turbo setups while providing significant performance gains for various engine sizes. Your choice of a single turbo can improve throttle response and overall engine output without the complexity of managing two turbochargers.

What is a Twin Turbo?

A twin turbo setup uses two turbochargers to increase engine efficiency and power by reducing turbo lag and providing better boost across a wider RPM range. This configuration can be arranged as parallel turbos, where each turbo feeds half of the engine's cylinders, or sequential turbos, where a smaller turbo operates at low RPM and a larger one kicks in at higher RPM. Twin turbos enhance performance by optimizing airflow and improving throttle response compared to a single turbo system.

Key Differences Between Single and Twin Turbo

Single turbo systems use one turbocharger to boost engine performance, offering simpler design and lower cost, while twin turbo setups employ two turbochargers to reduce lag and enhance power delivery across a wider RPM range. Twin turbos can be configured sequentially or in parallel, optimizing performance for specific driving conditions, whereas single turbos provide a balanced boost but may struggle with turbo lag at low RPMs. Your choice between single and twin turbo depends on desired power curve, response time, and vehicle application.

Performance Comparison

Single turbochargers typically offer quicker spool-up times and better low-end torque, enhancing responsiveness in everyday driving conditions. Twin turbo setups divide exhaust flow between two smaller turbines, reducing lag and significantly increasing peak power output for high-performance applications. Optimizing boost pressure and turbine sizing in twin turbos delivers superior acceleration and efficiency across a broader RPM range compared to single turbo configurations.

Cost and Maintenance Factors

Single turbo setups typically cost less upfront and require simpler maintenance due to fewer components, making them ideal for budget-conscious enthusiasts. Twin turbo systems often involve higher initial expenses and increased maintenance complexity because they have two turbochargers, more plumbing, and additional tuning requirements. You should consider your budget and willingness to maintain more intricate systems when choosing between single and twin turbo configurations.

Fuel Efficiency Implications

Single turbo systems generally offer better fuel efficiency due to their simpler design and reduced parasitic losses compared to twin turbo setups. Twin turbo configurations, while providing improved throttle response and increased power output, often result in higher fuel consumption because they require additional components and can increase turbo lag compensation fuel needs. Optimizing boost pressure and tuning for single turbo setups can maximize fuel economy benefits without significantly sacrificing performance.

Applications in Modern Vehicles

Single turbochargers are commonly found in smaller engines and entry-level performance cars due to their simpler design and quicker spool-up times, making them ideal for city driving and moderate power demands. Twin turbo setups dominate high-performance and luxury vehicles where enhanced power output and reduced turbo lag are critical, offering improved acceleration and efficiency across a broad RPM range. Your choice depends on the balance between power needs, vehicle type, and driving conditions.

Pros and Cons of Single Turbo

A single turbocharger offers simpler installation, lower cost, and reduced weight compared to twin turbo setups, making it ideal for budget builds and easier maintenance. However, single turbos may experience more turbo lag and less optimal power delivery across the RPM range than twin turbos, which can provide quicker spool times and better boost at lower RPMs. The choice between single and twin turbo systems depends on desired performance characteristics, engine size, and application goals.

Pros and Cons of Twin Turbo

Twin turbo setups deliver improved throttle response and increased power by using two smaller turbochargers instead of one large unit, reducing turbo lag and enhancing spool-up times. However, twin turbos add complexity to the engine system, leading to higher maintenance costs and potential reliability issues compared to single turbo setups. Your choice should balance the benefits of quicker boost and power distribution against the drawbacks of increased mechanical complexity and cost.

Single Turbo vs Twin Turbo Infographic

libmatt.com

libmatt.com