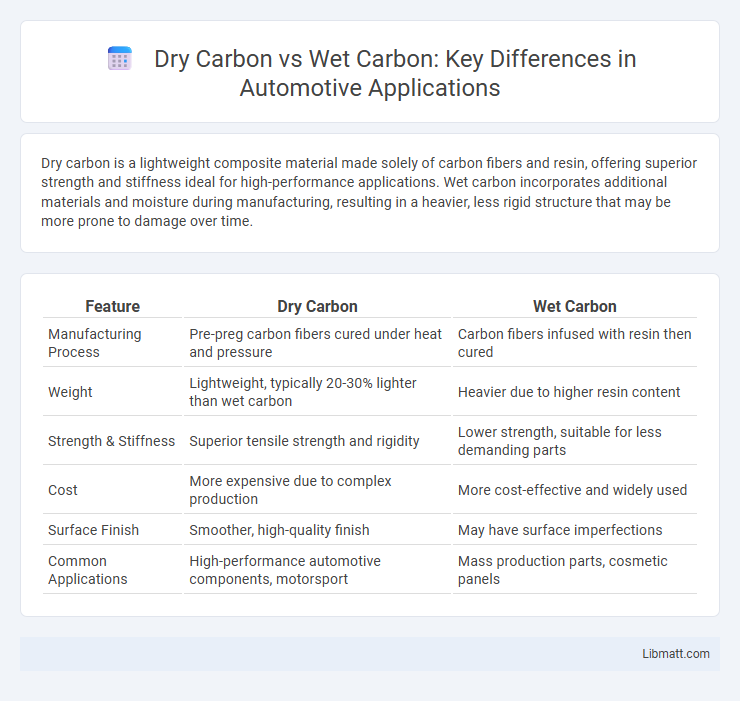

Dry carbon is a lightweight composite material made solely of carbon fibers and resin, offering superior strength and stiffness ideal for high-performance applications. Wet carbon incorporates additional materials and moisture during manufacturing, resulting in a heavier, less rigid structure that may be more prone to damage over time.

Table of Comparison

| Feature | Dry Carbon | Wet Carbon |

|---|---|---|

| Manufacturing Process | Pre-preg carbon fibers cured under heat and pressure | Carbon fibers infused with resin then cured |

| Weight | Lightweight, typically 20-30% lighter than wet carbon | Heavier due to higher resin content |

| Strength & Stiffness | Superior tensile strength and rigidity | Lower strength, suitable for less demanding parts |

| Cost | More expensive due to complex production | More cost-effective and widely used |

| Surface Finish | Smoother, high-quality finish | May have surface imperfections |

| Common Applications | High-performance automotive components, motorsport | Mass production parts, cosmetic panels |

Introduction to Dry Carbon and Wet Carbon

Dry carbon refers to carbon fiber pre-preg materials that are cured without added resins, resulting in lightweight and high-strength components ideal for aerospace and automotive industries. Wet carbon involves carbon fiber mats or fabrics infused with liquid resin during the manufacturing process, offering more flexibility in shaping but typically adding extra weight compared to dry carbon. Understanding the differences between dry and wet carbon helps you choose the best composite material for performance, durability, and cost-effectiveness in your specific application.

Key Differences Between Dry and Wet Carbon

Dry carbon consists of carbon fibers combined with resin, resulting in a lightweight, stiff, and durable composite often used in high-performance automotive and aerospace parts. Wet carbon is created by saturating carbon fibers with resin during the manufacturing process, allowing for more flexible shaping but generally producing a heavier and less rigid final product. The key differences lie in their manufacturing methods, weight, strength, cost, and application suitability, with dry carbon typically favored for its superior strength-to-weight ratio and wet carbon valued for complex shapes and lower production costs.

Manufacturing Processes: Dry Carbon vs Wet Carbon

Dry carbon manufacturing involves using unidirectional carbon fibers pre-impregnated with resin, which are laid and compressed under vacuum and heat to create lightweight, high-strength components with precise resin control. Wet carbon manufacturing saturates dry carbon fiber fabric with resin by hand, typically requiring more resin and resulting in heavier parts with less uniform strength. Your choice between dry and wet carbon impacts the part's weight, strength, and precision due to these distinct manufacturing process differences.

Material Composition and Structure

Dry carbon features unidirectional carbon fibers pre-impregnated with resin, resulting in a rigid structure with minimal resin content for enhanced strength-to-weight ratio. Wet carbon uses carbon fibers saturated with liquid resin during the manufacturing process, offering more flexibility but potentially higher resin weight. Your choice depends on whether you prioritize maximum stiffness and lightweight performance or greater adaptability in the material structure.

Weight Comparison: Dry Carbon vs Wet Carbon

Dry carbon fiber components weigh significantly less than wet carbon counterparts due to the absence of resin and resin-rich layers, resulting in a lighter overall structure. Wet carbon parts incorporate resin during the manufacturing process, adding to their weight and making them less optimal for applications where minimal weight is critical. The weight difference between dry and wet carbon can be up to 20%, giving dry carbon a clear advantage in high-performance automotive and aerospace industries.

Strength and Durability Analysis

Dry carbon fiber composites exhibit superior strength due to their higher fiber volume fraction and reduced resin content, resulting in increased stiffness and load-bearing capacity compared to wet carbon composites. Wet carbon, infused with resin during the layup process, offers better impact resistance and improved durability in harsh environmental conditions through enhanced resin bonding. Structural applications demanding high strength benefit from dry carbon, while wet carbon is preferred for durability where resistance to moisture and fatigue is critical.

Cost Implications and Pricing

Dry carbon components generally have higher manufacturing costs due to advanced curing processes and precision molding techniques, resulting in a premium price compared to wet carbon alternatives. Wet carbon, which uses a resin infusion process, offers a cost-effective solution with acceptable strength, making it popular for budget-conscious consumers. Pricing differences can range from 20% to 50%, depending on application and production volume, reflecting the trade-off between performance and affordability.

Applications in Automotive and Aerospace

Dry carbon composites offer superior stiffness and lightweight properties, making them ideal for high-performance automotive parts like body panels and structural components, as well as aerospace applications requiring precise tolerances and thermal stability. Wet carbon composites, processed with resin infusion methods, provide cost-effective solutions for larger, less structurally critical parts in both automotive and aerospace industries, including interior trims and secondary aircraft components. Your choice between dry and wet carbon materials depends on balancing performance requirements, manufacturing complexity, and budget constraints in these demanding sectors.

Aesthetic and Finish Differences

Dry carbon showcases a distinctive matte or satin finish with a tightly woven pattern that appeals to high-end automotive and aerospace designs, emphasizing lightweight strength and premium aesthetics. Wet carbon features a glossy, smoother surface due to its resin-rich layers, creating a more uniform and reflective appearance favored in consumer goods and sporting equipment. The finish differences not only affect visual appeal but also influence perceived quality and application suitability in various industries.

Which One to Choose: Dry Carbon or Wet Carbon?

Dry carbon offers superior stiffness, lightweight properties, and excellent durability, making it ideal for high-performance applications such as aerospace and automotive parts. Wet carbon incorporates resin during the manufacturing process, resulting in a smoother finish and enhanced impact resistance but usually adds weight compared to dry carbon. Choosing between dry carbon and wet carbon depends on balancing the need for strength and weight reduction versus cost-effectiveness and surface quality.

dry carbon vs wet carbon Infographic

libmatt.com

libmatt.com