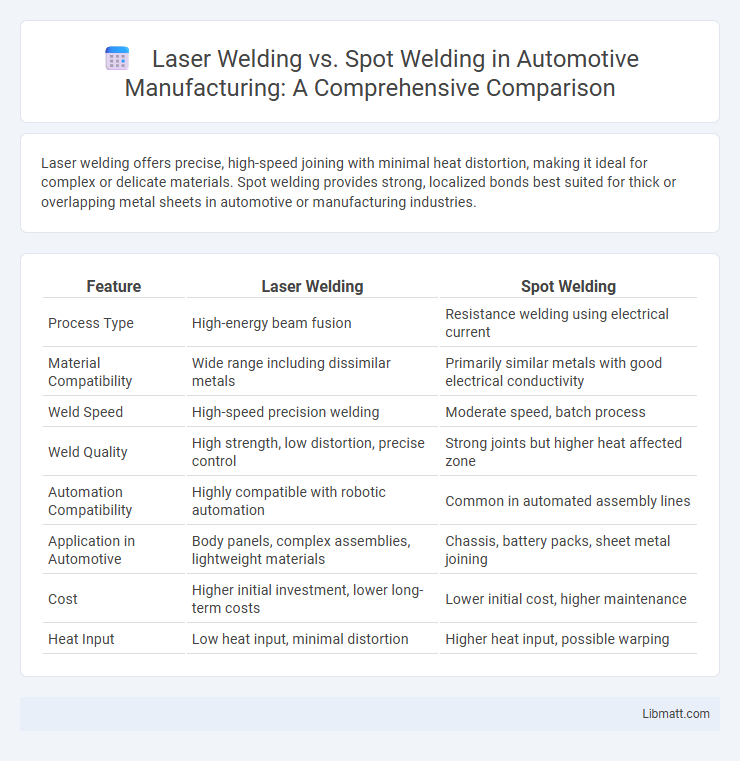

Laser welding offers precise, high-speed joining with minimal heat distortion, making it ideal for complex or delicate materials. Spot welding provides strong, localized bonds best suited for thick or overlapping metal sheets in automotive or manufacturing industries.

Table of Comparison

| Feature | Laser Welding | Spot Welding |

|---|---|---|

| Process Type | High-energy beam fusion | Resistance welding using electrical current |

| Material Compatibility | Wide range including dissimilar metals | Primarily similar metals with good electrical conductivity |

| Weld Speed | High-speed precision welding | Moderate speed, batch process |

| Weld Quality | High strength, low distortion, precise control | Strong joints but higher heat affected zone |

| Automation Compatibility | Highly compatible with robotic automation | Common in automated assembly lines |

| Application in Automotive | Body panels, complex assemblies, lightweight materials | Chassis, battery packs, sheet metal joining |

| Cost | Higher initial investment, lower long-term costs | Lower initial cost, higher maintenance |

| Heat Input | Low heat input, minimal distortion | Higher heat input, possible warping |

Introduction to Laser Welding and Spot Welding

Laser welding employs a high-energy laser beam to join metal parts with precision, producing narrow weld seams and minimal heat distortion. Spot welding, a resistance welding process, joins overlapping metal sheets by applying pressure and electric current to create localized weld spots. Both methods serve critical roles in automotive and manufacturing industries, with laser welding favored for its speed and accuracy, while spot welding is valued for its cost-effectiveness and simplicity.

Core Principles of Laser Welding

Laser welding utilizes a highly concentrated laser beam to melt and fuse materials together, enabling precise, deep penetration with minimal heat distortion. The core principles involve focusing the laser energy on a small spot to create a narrow, controlled weld pool, allowing for high welding speed and efficiency. This technique offers superior weld quality and strength compared to traditional spot welding, particularly in applications requiring minimal thermal impact and fine detail.

Key Processes in Spot Welding

Spot welding primarily involves the application of pressure and an electric current through copper alloy electrodes to localized metal surfaces, causing resistance heating that melts and joins the materials at the weld spot. The process relies on precise control of current magnitude, electrode force, and weld time to ensure consistent weld nugget formation and mechanical strength. Spot welding is widely used in automotive assembly and sheet metal fabrication for its speed and ability to produce strong, repeatable joints in thin metals.

Material Compatibility: Laser vs Spot Welding

Laser welding offers superior material compatibility, effectively joining a wide range of metals including stainless steel, aluminum, titanium, and dissimilar materials with minimal distortion. Spot welding is primarily suited for thin sheet metals like steel and nickel alloys but struggles with materials that have high thermal conductivity or thickness variations. Your choice depends on the specific metals involved and desired precision, with laser welding providing greater flexibility for complex or mixed-metal applications.

Speed and Efficiency Comparison

Laser welding delivers faster processing speeds with high precision, making it ideal for complex and thin materials, while spot welding excels in joining thicker metal sheets with rapid cycle times. You achieve higher efficiency in laser welding through minimal heat input and reduced distortion, whereas spot welding offers cost-effective mass production for large-scale assemblies. Choosing the right method depends on your specific speed requirements and material characteristics to maximize productivity.

Precision and Weld Quality

Laser welding delivers superior precision and weld quality due to its highly focused heat source, allowing for minimal distortion and narrow weld seams. Spot welding, while effective for joining sheet metals quickly, offers less control over heat input and weld size, which can lead to weaker welds and increased material deformation. Your choice depends on the need for detailed, high-strength joints where laser welding provides more consistent and aesthetically clean results.

Equipment Requirements and Costs

Laser welding requires highly specialized equipment such as high-powered lasers, precise optics, and advanced control systems, leading to higher initial investment and maintenance costs compared to spot welding. Spot welding uses simpler, more affordable equipment like electrodes and presses, making it a cost-effective choice for high-volume production with thicker materials. Your decision should balance the precision and speed advantages of laser welding against the lower equipment costs and ease of implementation offered by spot welding.

Applications in Industry

Laser welding offers precise, high-speed joining ideal for automotive manufacturing, aerospace components, and medical device production where accuracy and minimal heat distortion are critical. Spot welding is widely used in the automotive industry for assembling sheet metal parts, electrical components, and appliance manufacturing due to its efficiency and cost-effectiveness in mass production. Your choice between laser and spot welding depends on the specific application requirements, including material type, thickness, and desired production volume.

Safety and Environmental Considerations

Laser welding offers enhanced safety through precise control and reduced risk of exposure to fumes and sparks compared to spot welding, which often generates significant smoke and requires strict ventilation. Environmentally, laser welding produces less waste and consumes lower energy due to its high efficiency and minimal material distortion. Proper protective equipment and adherence to safety standards are critical in both methods to mitigate hazards associated with intense heat and ultraviolet radiation.

Choosing the Right Welding Method

Choosing the right welding method depends on factors such as material thickness, production speed, and precision requirements. Laser welding offers high precision and minimal thermal distortion, making it ideal for thin metals and intricate joints. Spot welding excels in rapid, cost-effective joining of sheet metals, especially in automotive and manufacturing applications requiring strong, consistent welds.

Laser welding vs Spot welding Infographic

libmatt.com

libmatt.com