Swirl ports create a rotational air motion inside the combustion chamber, improving fuel-air mixing and enhancing combustion efficiency, while tumble ports generate a vertical tumbling motion that promotes better flame propagation and stability. Understanding the difference between swirl and tumble ports helps optimize engine performance and fuel economy based on your specific vehicle requirements.

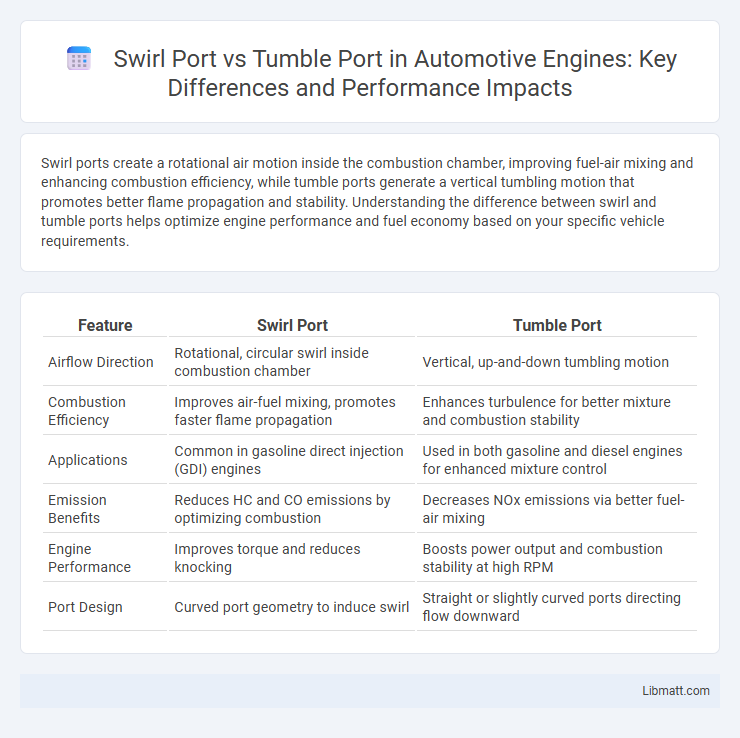

Table of Comparison

| Feature | Swirl Port | Tumble Port |

|---|---|---|

| Airflow Direction | Rotational, circular swirl inside combustion chamber | Vertical, up-and-down tumbling motion |

| Combustion Efficiency | Improves air-fuel mixing, promotes faster flame propagation | Enhances turbulence for better mixture and combustion stability |

| Applications | Common in gasoline direct injection (GDI) engines | Used in both gasoline and diesel engines for enhanced mixture control |

| Emission Benefits | Reduces HC and CO emissions by optimizing combustion | Decreases NOx emissions via better fuel-air mixing |

| Engine Performance | Improves torque and reduces knocking | Boosts power output and combustion stability at high RPM |

| Port Design | Curved port geometry to induce swirl | Straight or slightly curved ports directing flow downward |

Introduction to Swirl Port and Tumble Port

Swirl port and tumble port are combustion chamber designs that enhance air-fuel mixing in internal combustion engines. Swirl ports create a rotating motion of the intake air around the cylinder axis, improving atomization and combustion efficiency. Tumble ports generate a tumbling motion perpendicular to the cylinder axis, increasing turbulence and promoting faster flame propagation for better engine performance.

Understanding Airflow Dynamics in Combustion Chambers

Swirl ports create a rotational airflow inside the combustion chamber, enhancing air-fuel mixture turbulence and promoting more efficient combustion. Tumble ports generate a vertical airflow tumble motion, improving cylinder filling and reducing emissions by ensuring better fuel atomization. Understanding how swirl and tumble port designs influence airflow dynamics helps optimize combustion chamber performance, ultimately improving your engine's power and fuel efficiency.

Swirl Ports: Mechanism and Benefits

Swirl ports in internal combustion engines create a rotational airflow pattern that enhances air-fuel mixture atomization and distribution within the combustion chamber. This swirling effect improves combustion efficiency by promoting more complete fuel burn, resulting in lower emissions and increased power output. The optimized turbulence from swirl ports also aids in reducing knocking and supports better cold-start performance.

Tumble Ports: Mechanism and Applications

Tumble ports create a rotational air movement inside the combustion chamber, enhancing fuel-air mixing for better combustion efficiency and reduced emissions. This mechanism is particularly effective in gasoline engines, improving cold-start performance and fuel economy by promoting faster flame propagation. Your engine's responsiveness and emission control benefit significantly from the precise airflow management enabled by tumble ports.

Swirl Port vs Tumble Port: Key Differences

Swirl ports create a rotational air movement inside the combustion chamber, enhancing air-fuel mixture and improving combustion efficiency, especially at low engine speeds. Tumble ports generate a vertical, tumbling airflow that promotes better mixing and faster flame propagation during combustion, which benefits high-speed performance. Understanding these differences helps optimize Your engine design for specific power and emission goals.

Impact on Engine Performance and Efficiency

Swirl port design enhances air-fuel mixture turbulence, promoting better combustion efficiency and increasing torque at low to mid engine speeds. Tumble ports generate vertical airflow patterns that optimize fuel atomization and combustion stability, leading to improved power output and reduced emissions at higher engine speeds. Efficient port design directly influences volumetric efficiency, fuel economy, and overall engine performance by optimizing intake airflow dynamics.

Emission Control: Swirl vs Tumble Dynamics

Swirl port designs enhance fuel-air mixing by creating a rotational airflow around the cylinder axis, promoting more complete combustion and reducing unburned hydrocarbons and carbon monoxide emissions. In contrast, tumble ports generate a vertical vortex that improves flame propagation speed and allows for leaner combustion mixtures, leading to lower nitrogen oxide (NOx) emissions. Optimizing the balance between swirl and tumble dynamics is crucial for achieving stringent emission control and improving overall engine efficiency.

Suitability for Different Engine Types

Swirl ports are optimized for small to medium displacement engines, enhancing fuel-air mixture homogeneity and combustion efficiency in low to mid-RPM applications. Tumble ports suit high-performance and turbocharged engines where rapid intake air movement is essential for better cylinder filling and higher power output at elevated RPMs. The choice between swirl and tumble port designs depends on engine size, desired power characteristics, and emission targets.

Technological Innovations in Intake Port Design

Swirl port and tumble port designs represent key technological innovations in intake port engineering to enhance air-fuel mixture quality and combustion efficiency. Swirl ports induce a rotational airflow around the cylinder axis, promoting better atomization and faster flame propagation, which improves power output and reduces emissions. Tumble ports create a tumbling motion perpendicular to the cylinder axis, enhancing mixture homogeneity and thermal efficiency, especially beneficial in direct injection engines and stratified charge combustion systems.

Future Trends in Port Optimization

Swirl ports enhance air-fuel mixture quality by inducing a strong rotational airflow, while tumble ports focus on creating vertical airflow patterns for improved combustion efficiency. Future trends in port optimization emphasize integrating adaptive port designs using variable geometry technology to dynamically adjust airflow characteristics for different engine loads and speeds. Advances in computational fluid dynamics (CFD) and machine learning algorithms enable precise tuning of swirl and tumble ports, aiming to maximize fuel economy and reduce emissions in next-generation internal combustion engines.

swirl port vs tumble port Infographic

libmatt.com

libmatt.com