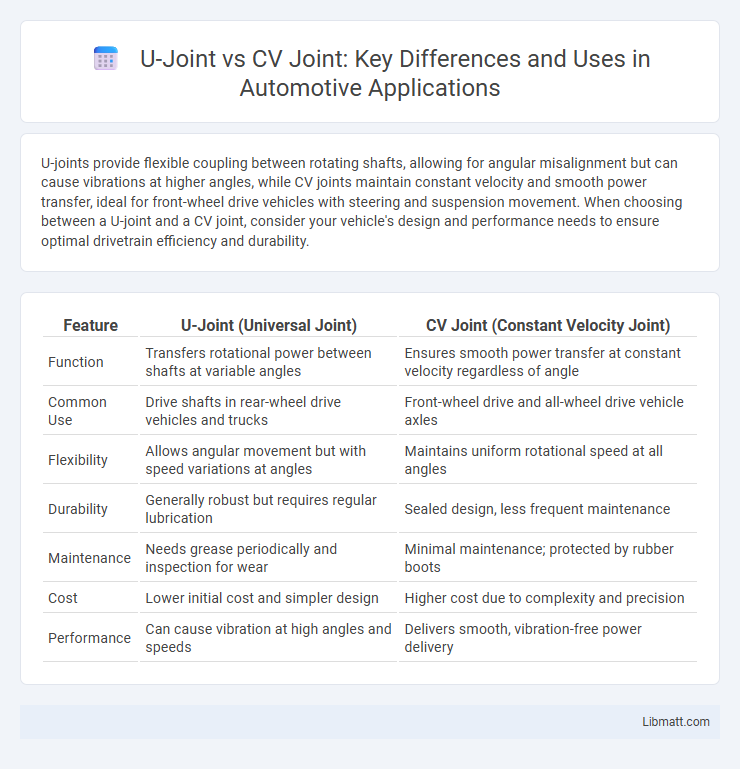

U-joints provide flexible coupling between rotating shafts, allowing for angular misalignment but can cause vibrations at higher angles, while CV joints maintain constant velocity and smooth power transfer, ideal for front-wheel drive vehicles with steering and suspension movement. When choosing between a U-joint and a CV joint, consider your vehicle's design and performance needs to ensure optimal drivetrain efficiency and durability.

Table of Comparison

| Feature | U-Joint (Universal Joint) | CV Joint (Constant Velocity Joint) |

|---|---|---|

| Function | Transfers rotational power between shafts at variable angles | Ensures smooth power transfer at constant velocity regardless of angle |

| Common Use | Drive shafts in rear-wheel drive vehicles and trucks | Front-wheel drive and all-wheel drive vehicle axles |

| Flexibility | Allows angular movement but with speed variations at angles | Maintains uniform rotational speed at all angles |

| Durability | Generally robust but requires regular lubrication | Sealed design, less frequent maintenance |

| Maintenance | Needs grease periodically and inspection for wear | Minimal maintenance; protected by rubber boots |

| Cost | Lower initial cost and simpler design | Higher cost due to complexity and precision |

| Performance | Can cause vibration at high angles and speeds | Delivers smooth, vibration-free power delivery |

Introduction to U-Joints and CV Joints

U-joints (universal joints) transmit rotational power between two angled shafts, commonly found in drive shafts of rear-wheel-drive vehicles, allowing for flexibility in motion. CV (constant velocity) joints maintain a constant rotational speed regardless of the angle between the drive shaft and the wheel hub, essential for front-wheel-drive and all-wheel-drive vehicles to provide smooth power delivery during steering. Understanding the differences between U-joints and CV joints ensures you select the right component for your vehicle's drivetrain performance and durability.

Basic Function and Purpose

U-joints (universal joints) enable rotational power transfer between shafts at varying angles, primarily in rear-wheel-drive vehicles and driveshafts. CV joints (constant velocity joints) maintain a constant rotational speed without fluctuations, essential for front-wheel-drive cars' steering and suspension movements. Your choice depends on your vehicle's drivetrain configuration and the smoothness of power transmission needed.

Design and Construction Differences

U-joints (universal joints) consist of a simple cross-shaped pivot with needle bearings allowing rotational flexibility in two planes, typically made of hardened steel for durability. CV joints (constant velocity joints) feature a more complex design with a spherical inner race and cage, enabling smooth power transfer through a wide range of angles without speed fluctuations, often incorporating precision-machined components and lubricant seals. The U-joint's construction suits applications with moderate angular movement, while the CV joint's intricate assembly supports greater articulation and consistent velocity essential for front-wheel-drive and all-wheel-drive vehicles.

Types of Applications

U-joints are commonly used in applications requiring the transmission of rotary motion between two shafts at varying angles, such as in drive shafts of rear-wheel-drive vehicles and industrial machinery. CV joints, on the other hand, are primarily designed for front-wheel-drive automobile axles, allowing consistent torque transfer while accommodating the up-and-down motion of suspension and steering angles. Off-road vehicles and high-performance cars often utilize both joint types for optimized power delivery and flexibility.

Performance Under Load

U-joints (universal joints) handle high torque loads effectively but exhibit vibration and speed fluctuations at extreme angles, limiting smooth power transfer. CV joints (constant velocity joints) maintain consistent rotational speed and torque transmission under varying angles, enhancing drivetrain efficiency and vehicle stability. Performance under load clearly favors CV joints in applications requiring smooth, reliable power delivery during high articulation.

Maintenance Requirements

U-joints require regular lubrication to prevent wear and avoid joint failure, often needing grease at specified service intervals. CV joints, typically sealed and filled with grease, demand less frequent maintenance but should be inspected for torn boots that could lead to contamination and joint damage. Proper attention to lubrication and boot condition ensures longevity and optimal performance of both types of joints in automotive drivetrains.

Common Failure Modes

U-joints commonly fail due to bearing wear and lack of lubrication, leading to vibration and joint binding during rotation. CV joints typically experience boot cracks or tears, allowing dirt and moisture to enter, which causes grease leakage and accelerated joint wear. Understanding these failure modes helps you identify symptoms early and maintain your vehicle's drivetrain components effectively.

Cost and Replacement Considerations

U-joints generally have a lower initial cost and simpler replacement process compared to CV joints, making them more budget-friendly for vehicles with basic drivetrains. CV joints tend to be more expensive due to their complex design and the precision engineering required for constant velocity operation, often leading to higher labor costs during replacement. Regular maintenance and timely inspection of both joint types can prevent costly repairs, but CV joints typically demand more frequent attention because of their critical role in front-wheel-drive and all-wheel-drive systems.

Advantages and Disadvantages

U-joints offer robust durability and can handle high torque loads, making them ideal for heavy-duty applications such as trucks and off-road vehicles; however, they can cause vibrations and wear out faster at extreme angles compared to CV joints. CV joints provide smoother power transfer and maintain constant velocity at varying angles, which enhances driving comfort and efficiency, but they are more complex and typically costlier to repair or replace. Both joints require regular maintenance, with CV joints often needing protective boots to prevent contamination and premature failure.

Choosing the Right Joint for Your Vehicle

Choosing the right joint for your vehicle depends on the drivetrain configuration and required flexibility. U-joints (universal joints) are ideal for vehicles with solid axles and offer durability for off-road and heavy-duty use, while CV joints (constant velocity joints) provide smooth power transfer in front-wheel-drive and independent suspension systems. Consider factors such as joint angle, torque capacity, and maintenance needs to ensure optimal performance and longevity.

U-joint vs CV joint Infographic

libmatt.com

libmatt.com