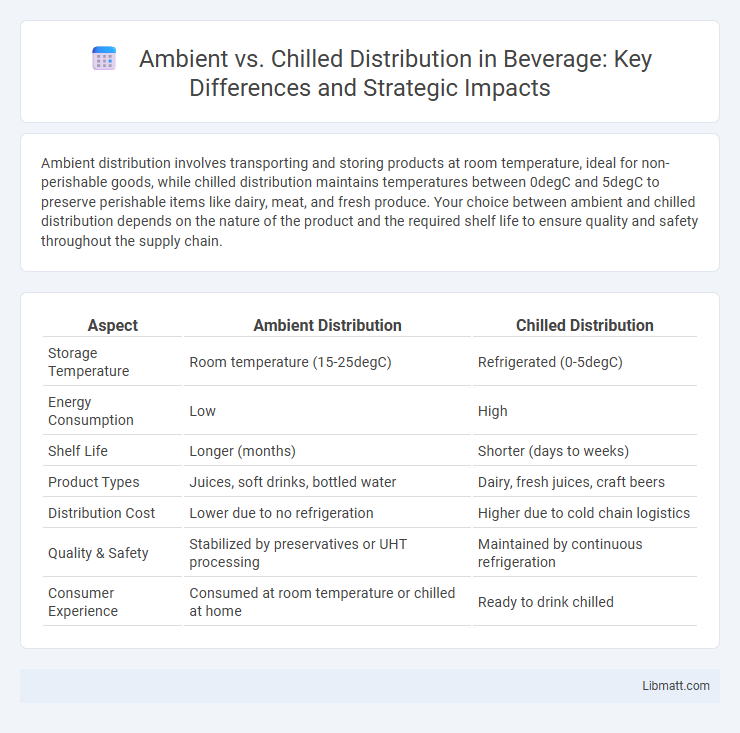

Ambient distribution involves transporting and storing products at room temperature, ideal for non-perishable goods, while chilled distribution maintains temperatures between 0degC and 5degC to preserve perishable items like dairy, meat, and fresh produce. Your choice between ambient and chilled distribution depends on the nature of the product and the required shelf life to ensure quality and safety throughout the supply chain.

Table of Comparison

| Aspect | Ambient Distribution | Chilled Distribution |

|---|---|---|

| Storage Temperature | Room temperature (15-25degC) | Refrigerated (0-5degC) |

| Energy Consumption | Low | High |

| Shelf Life | Longer (months) | Shorter (days to weeks) |

| Product Types | Juices, soft drinks, bottled water | Dairy, fresh juices, craft beers |

| Distribution Cost | Lower due to no refrigeration | Higher due to cold chain logistics |

| Quality & Safety | Stabilized by preservatives or UHT processing | Maintained by continuous refrigeration |

| Consumer Experience | Consumed at room temperature or chilled at home | Ready to drink chilled |

Understanding Ambient and Chilled Distribution

Ambient distribution involves transporting products at room temperature, typically ranging from 15degC to 25degC, making it ideal for non-perishable goods such as canned foods, snacks, and beverages. Chilled distribution requires maintaining temperatures between 0degC and 4degC, crucial for preserving freshness and safety of perishable items like dairy, meat, and fresh produce. Understanding these differences helps you optimize supply chain efficiency and ensure product integrity throughout delivery.

Key Differences Between Ambient and Chilled Distribution

Ambient distribution involves transporting goods at room temperature, suitable for non-perishable items like canned foods and dry goods, which reduces energy costs and simplifies logistics. Chilled distribution maintains products between 0degC and 5degC, essential for perishable items such as dairy, meat, and fresh produce to prevent spoilage and extend shelf life. The key differences lie in temperature control requirements, energy consumption, and product handling protocols to ensure food safety and quality during transit.

Temperature Requirements: Ambient vs Chilled

Ambient distribution maintains products at room temperature, typically between 15degC and 25degC, suitable for goods that are shelf-stable without refrigeration. Chilled distribution requires controlled temperatures, usually between 2degC and 8degC, to preserve perishable items like dairy, meat, and pharmaceuticals by slowing microbial growth and maintaining freshness. Your choice between ambient and chilled distribution directly impacts product quality, safety, and shelf life, necessitating precise temperature monitoring and handling protocols.

Product Types Suitable for Each Distribution Method

Ambient distribution suits shelf-stable products such as canned goods, dry snacks, and beverages that do not require refrigeration. Chilled distribution is ideal for perishable items like dairy products, fresh meats, and ready-to-eat meals that depend on temperature control to maintain freshness and safety. Choosing the right distribution method ensures your products retain quality during transit and storage, aligning with their specific preservation needs.

Packaging Considerations for Ambient and Chilled Goods

Packaging for ambient goods must prioritize barrier properties to protect against moisture, oxygen, and light, ensuring shelf stability without refrigeration. Chilled goods packaging requires controlled permeability materials to maintain optimal temperature and humidity, extending freshness and preventing microbial growth. Both types demand robust sealing techniques and materials that support product integrity while facilitating safe transportation and storage.

Cost Implications: Ambient vs Chilled Logistics

Ambient distribution typically incurs lower transportation and storage costs due to the absence of refrigeration requirements, resulting in reduced energy consumption and simpler infrastructure. Chilled logistics demand specialized refrigerated vehicles and cold storage facilities, significantly increasing operational expenses and energy usage. The choice between ambient and chilled distribution impacts overall supply chain costs, with ambient offering cost-efficiency and chilled providing enhanced product quality and shelf life.

Regulatory Compliance and Food Safety Standards

Ambient and chilled distribution must strictly adhere to regulatory compliance and food safety standards to prevent contamination and spoilage. Regulatory agencies such as the FDA and EFSA require temperature control protocols specific to chilled goods, ensuring products remain within safe microbial limits. You can enhance food safety by implementing validated monitoring systems, detailed traceability, and adherence to HACCP guidelines tailored for each distribution type.

Storage and Transportation Challenges

Ambient distribution faces fewer temperature control requirements but poses risks of product degradation due to fluctuating environmental conditions. Chilled distribution demands consistent refrigeration, requiring specialized insulated packaging and temperature-monitored transport systems to maintain the cold chain integrity. Both methods must address challenges such as transit delays and handling errors to ensure product quality and safety.

Sustainability and Environmental Impact

Ambient distribution reduces energy consumption by eliminating the need for refrigeration, significantly lowering carbon emissions compared to chilled distribution, which relies heavily on continuous cooling systems. Your choice of ambient logistics supports sustainability by minimizing electricity usage and reducing the carbon footprint associated with cold chain transportation. However, chilled distribution remains essential for perishable goods, where environmental impact can be mitigated through energy-efficient refrigeration technologies and renewable energy sources.

Choosing the Right Distribution Method for Your Business

Selecting the ideal distribution method depends on product type, shelf life, and target market. Ambient distribution suits non-perishable goods requiring room temperature storage, reducing logistics costs and simplifying inventory management. Chilled distribution is essential for perishable products needing controlled temperatures to maintain freshness and comply with safety standards, ensuring product quality and customer satisfaction.

Ambient vs chilled distribution Infographic

libmatt.com

libmatt.com