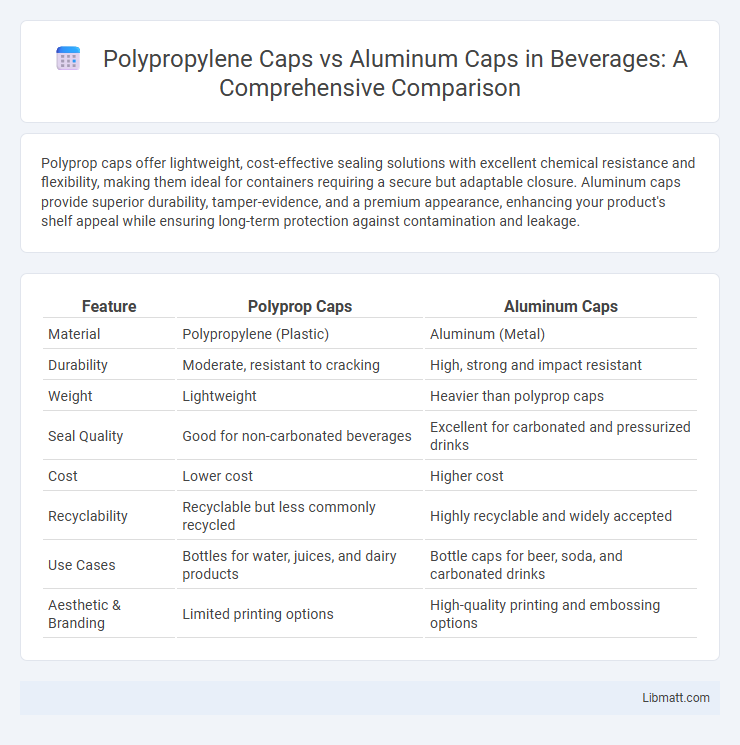

Polyprop caps offer lightweight, cost-effective sealing solutions with excellent chemical resistance and flexibility, making them ideal for containers requiring a secure but adaptable closure. Aluminum caps provide superior durability, tamper-evidence, and a premium appearance, enhancing your product's shelf appeal while ensuring long-term protection against contamination and leakage.

Table of Comparison

| Feature | Polyprop Caps | Aluminum Caps |

|---|---|---|

| Material | Polypropylene (Plastic) | Aluminum (Metal) |

| Durability | Moderate, resistant to cracking | High, strong and impact resistant |

| Weight | Lightweight | Heavier than polyprop caps |

| Seal Quality | Good for non-carbonated beverages | Excellent for carbonated and pressurized drinks |

| Cost | Lower cost | Higher cost |

| Recyclability | Recyclable but less commonly recycled | Highly recyclable and widely accepted |

| Use Cases | Bottles for water, juices, and dairy products | Bottle caps for beer, soda, and carbonated drinks |

| Aesthetic & Branding | Limited printing options | High-quality printing and embossing options |

Introduction to Bottle Caps: Polyprop vs Aluminum

Polyprop caps offer lightweight, chemical-resistant sealing ideal for diverse liquid products, while aluminum caps provide superior durability and a premium appearance often used for beverages and spirits. Your choice between polyprop and aluminum caps depends on factors like product compatibility, environmental impact, and desired shelf appeal. Polypropylene caps excel in flexibility and cost-effectiveness, whereas aluminum caps deliver strong tamper evidence and recyclability benefits.

Material Composition: Polypropylene and Aluminum Explained

Polyprop caps are made from polypropylene, a lightweight, flexible plastic known for its chemical resistance and durability in various packaging applications, ensuring a secure seal for your products. Aluminum caps consist of metal alloy with excellent barrier properties, providing superior protection against moisture, light, and oxygen, which helps preserve product freshness. Choosing between polypropylene and aluminum caps depends on your packaging needs, balancing flexibility and environmental exposure with strength and preservation capabilities.

Manufacturing Process Differences

Polyprop caps are manufactured using injection molding, which allows for precise shaping and cost-effective mass production, while aluminum caps typically undergo stamping and rolling processes followed by sealing. The injection molding of polyprop ensures consistent thickness and flexibility, whereas aluminum caps require additional finishing steps like anodizing or coating to prevent corrosion and enhance durability. Your choice depends on the desired durability, appearance, and compatibility with the product's packaging requirements.

Environmental Impact and Recyclability

Polyprop caps have a lower environmental impact due to their lightweight nature and compatibility with existing plastic recycling streams, making them easier to recycle compared to aluminum caps, which require more energy-intensive processes to recycle. Aluminum caps, while durable and fully recyclable, contribute to higher carbon emissions during production and recycling if not processed properly. Choosing polyprop caps can enhance your product's sustainability profile by reducing overall waste and promoting circular economy practices.

Performance: Seal Quality and Durability

Polyprop caps offer superior seal quality for plastic containers due to their flexibility and resistance to chemical corrosion, ensuring long-lasting freshness. Aluminum caps provide excellent durability and a strong, tamper-evident seal ideal for glass bottles, but they may be prone to deformation under impact. Your choice depends on the container material and the specific performance requirements for maintaining product integrity.

Cost Comparison: Polyprop Caps vs Aluminum Caps

Polypropylene caps generally cost less than aluminum caps due to lower raw material prices and simpler manufacturing processes, making them a budget-friendly option for high-volume packaging. Aluminum caps offer superior durability and premium appearance but come with higher production costs influenced by metal prices and energy-intensive fabrication. Choosing between polyprop and aluminum caps depends on balancing cost-efficiency with product protection and branding considerations.

Compatibility with Different Packaging

Polyprop caps offer superior compatibility with a wide range of plastic and glass bottles due to their flexible sealing properties and resistance to chemical interaction. Aluminum caps provide excellent durability and barrier protection, making them ideal for metal cans, glass jars, and high-pressure containers but may require liners to ensure a proper seal with certain plastics. Choosing between polyprop and aluminum caps depends on the packaging material, product sensitivity, and sealing requirements to maintain product integrity.

Consumer Safety and Tamper Evidence

Polyprop caps offer superior consumer safety through their non-toxic, BPA-free composition that minimizes chemical leaching into food and beverages, ensuring safer consumption. Aluminum caps provide robust tamper-evident features with visible seals and crimps that clearly indicate any unauthorized access, enhancing product integrity. While polyprop caps often incorporate integrated tamper-evident bands or breakable seals, aluminum caps excel in airtight sealing, reducing contamination risk and maintaining consumer trust.

Branding and Customization Options

Polyprop caps offer extensive branding opportunities with vibrant color choices, embossed logos, and custom shapes, enhancing your product's visual appeal and shelf presence. Aluminum caps provide a premium look with high-quality finishes and embossing that convey luxury and durability, ideal for upscale brands. Your choice depends on the balance between cost-effective customization and a sophisticated, high-end brand image.

Market Trends and Industry Preferences

Polyprop caps dominate the market due to their lightweight nature, cost-effectiveness, and recyclability, aligning with increasing consumer demand for sustainable packaging solutions. Aluminum caps remain preferred in industries such as beverages and pharmaceuticals because of their superior barrier properties and premium appearance. Your choice between polyprop and aluminum caps should consider evolving industry preferences favoring eco-friendly materials without compromising product protection.

Polyprop caps vs aluminum caps Infographic

libmatt.com

libmatt.com