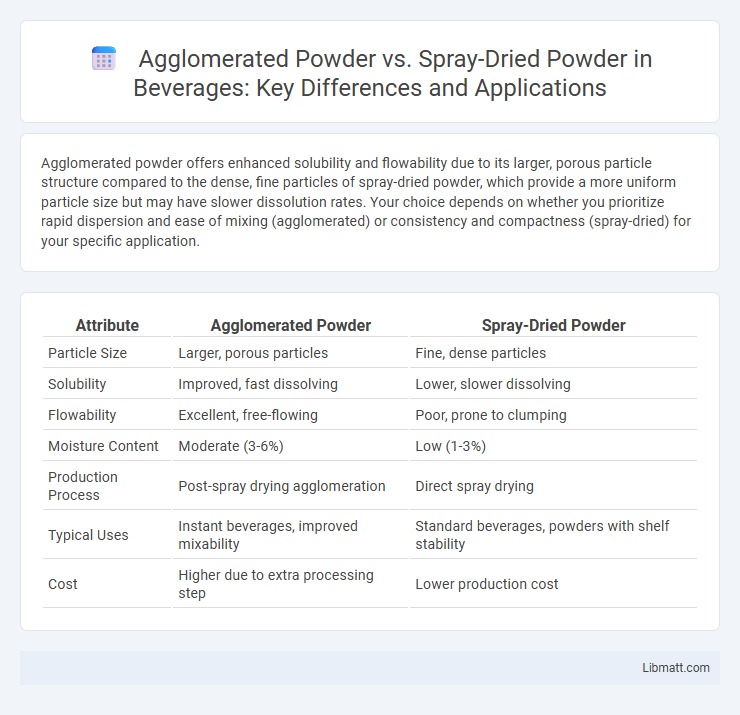

Agglomerated powder offers enhanced solubility and flowability due to its larger, porous particle structure compared to the dense, fine particles of spray-dried powder, which provide a more uniform particle size but may have slower dissolution rates. Your choice depends on whether you prioritize rapid dispersion and ease of mixing (agglomerated) or consistency and compactness (spray-dried) for your specific application.

Table of Comparison

| Attribute | Agglomerated Powder | Spray-Dried Powder |

|---|---|---|

| Particle Size | Larger, porous particles | Fine, dense particles |

| Solubility | Improved, fast dissolving | Lower, slower dissolving |

| Flowability | Excellent, free-flowing | Poor, prone to clumping |

| Moisture Content | Moderate (3-6%) | Low (1-3%) |

| Production Process | Post-spray drying agglomeration | Direct spray drying |

| Typical Uses | Instant beverages, improved mixability | Standard beverages, powders with shelf stability |

| Cost | Higher due to extra processing step | Lower production cost |

Introduction to Agglomerated and Spray-Dried Powders

Agglomerated powder consists of fine particles bound together to form larger, porous granules that enhance solubility and flow properties, crucial in food and pharmaceutical applications. Spray-dried powder is produced by rapidly drying liquid feed into a fine, uniform powder through atomization in a hot air stream, preserving heat-sensitive components and ensuring consistent particle size. Both techniques optimize powder characteristics for improved reconstitution, handling, and stability in diverse product formulations.

Defining Agglomerated Powder

Agglomerated powder is a type of powder formed by the process of binding fine particles into larger, porous granules to improve flowability, dispersibility, and solubility in liquid applications. Unlike spray-dried powder, which is created by atomizing a liquid feed into a hot drying chamber resulting in fine, dense particles, agglomerated powder undergoes an additional granulation step that enhances reconstitution properties. This process makes agglomerated powder ideal for use in food, pharmaceutical, and chemical industries where rapid dissolving and consistent texture are critical.

What is Spray-Dried Powder?

Spray-dried powder is produced by rapidly drying a liquid feed through a hot gas stream, resulting in fine, uniform particles with controlled moisture content. This process preserves the functional properties and solubility of the original material, making it ideal for pharmaceuticals, food ingredients, and ceramics. Compared to agglomerated powder, spray-dried powder offers superior flowability and consistent particle size distribution, enhancing mixing and processing efficiency.

Key Differences in Production Processes

Agglomerated powder is produced by rewetting fine powder particles with a liquid binder, causing them to clump together and form larger granules, which improves flowability and solubility. Spray-dried powder is created by spraying a liquid feed into a hot drying chamber, rapidly evaporating moisture and forming fine, porous particles. Your choice depends on factors like desired particle size, moisture content, and the specific properties required for your application.

Particle Size and Morphology Comparison

Agglomerated powders typically exhibit larger, porous particles formed by the bonding of smaller primary particles, resulting in a more irregular and rough morphology, which enhances flowability and dispersibility. Spray-dried powders consist of fine, spherical, and dense particles created through rapid solvent evaporation, yielding uniform particle size distribution and smooth surface morphology. The particle size of agglomerated powders generally ranges from 50 to 500 microns, whereas spray-dried powders are finer, often between 10 to 100 microns.

Solubility and Dissolution Rates

Agglomerated powder typically exhibits enhanced solubility and faster dissolution rates compared to spray-dried powder due to its larger, porous granules that promote better wetting and dispersion in liquids. Spray-dried powders often have smaller, denser particles, which can lead to slower solubility and dissolution because of reduced surface area contact with solvents. You can improve the efficiency of your formulations by choosing agglomerated powders when rapid dissolution is critical for product performance.

Flowability and Handling Characteristics

Agglomerated powder exhibits superior flowability and handling characteristics compared to spray-dried powder due to its larger, porous granules that reduce dust generation and improve cohesion. Spray-dried powder, while fine and uniform, often suffers from poor flowability and increased caking, making it more challenging to handle in manufacturing processes. Optimizing your formulation with agglomerated powder enhances powder flow, reduces processing downtime, and ensures more consistent dosing in production lines.

Applications in Food and Pharmaceutical Industries

Agglomerated powder offers superior flowability and solubility, making it ideal for instant drink mixes, powdered soups, and pharmaceutical granules requiring rapid dissolution. Spray-dried powder provides uniform particle size and enhanced stability, which benefits the encapsulation of flavors, probiotics, and active pharmaceutical ingredients in tablets and capsules. Choosing the right powder type depends on your specific application needs in food texture, mixing efficiency, or drug delivery performance.

Advantages and Disadvantages of Each Powder Type

Agglomerated powder offers improved flowability and solubility due to its porous structure, making it ideal for instant beverage formulations, but it may be more prone to moisture absorption and caking. Spray-dried powder provides uniform particle size and better preservation of heat-sensitive nutrients but can exhibit poor flow properties and dustiness, affecting processing efficiency. Your choice depends on balancing these trade-offs based on application requirements like solubility, texture, and shelf-life stability.

Choosing the Right Powder for Your Needs

Agglomerated powder offers improved flowability and solubility due to its larger, porous particles, making it ideal for instant beverage formulations or products requiring quick dissolution. Spray-dried powder provides finer particles with consistent particle size, suitable for applications requiring smooth texture and uniform mixing, such as in bakery or dairy products. Assess your product's processing requirements and desired final texture to determine whether the superior dispersibility of agglomerated powder or the uniformity of spray-dried powder better aligns with your manufacturing goals.

Agglomerated powder vs spray-dried powder Infographic

libmatt.com

libmatt.com