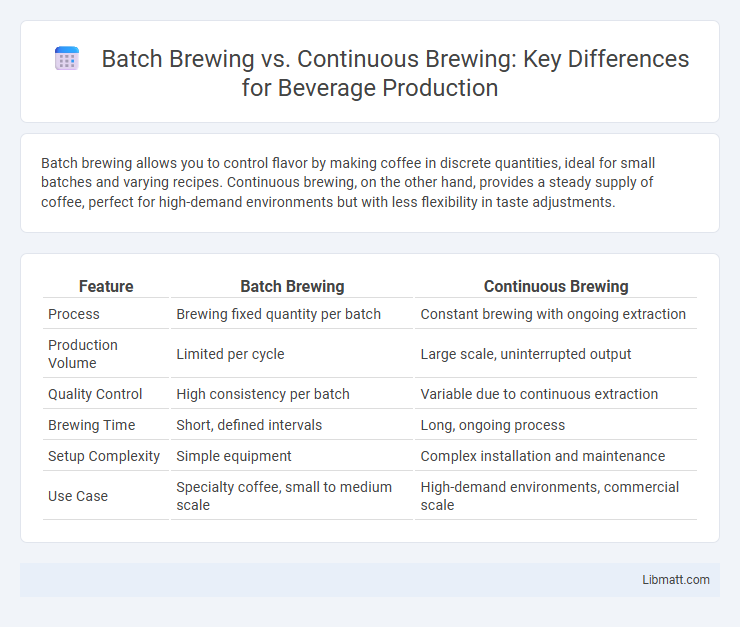

Batch brewing allows you to control flavor by making coffee in discrete quantities, ideal for small batches and varying recipes. Continuous brewing, on the other hand, provides a steady supply of coffee, perfect for high-demand environments but with less flexibility in taste adjustments.

Table of Comparison

| Feature | Batch Brewing | Continuous Brewing |

|---|---|---|

| Process | Brewing fixed quantity per batch | Constant brewing with ongoing extraction |

| Production Volume | Limited per cycle | Large scale, uninterrupted output |

| Quality Control | High consistency per batch | Variable due to continuous extraction |

| Brewing Time | Short, defined intervals | Long, ongoing process |

| Setup Complexity | Simple equipment | Complex installation and maintenance |

| Use Case | Specialty coffee, small to medium scale | High-demand environments, commercial scale |

Introduction to Brewing Methods

Batch brewing produces coffee in discrete quantities, allowing precise control over extraction time and flavor consistency, commonly used in drip coffee makers. Continuous brewing continuously cycles water through coffee grounds, ideal for high-volume environments, offering a uniform taste but less flexibility in adjusting individual brew strength. Both methods impact the coffee's flavor profile and operational efficiency differently, influencing equipment choice and brewing strategy in commercial and home settings.

What is Batch Brewing?

Batch brewing involves producing coffee in specific, measured quantities by extracting a set volume of water through a fixed amount of coffee grounds per cycle, allowing precise control over flavor and strength. Its method is ideal for smaller, consistent servings, making it popular in specialty coffee shops for maintaining quality across individual batches. Understanding your preferences with batch brewing provides you the ability to tailor each brew to your desired taste profile.

What is Continuous Brewing?

Continuous brewing is a fermentation process in which beer or other beverages are produced without interruption by constantly adding fresh ingredients while simultaneously removing finished product. This method maintains a steady state of fermentation, optimizing production efficiency and consistency in flavor profiles. Continuous brewing is widely used in large-scale commercial operations to maximize output and reduce downtime compared to traditional batch brewing.

Equipment Needed for Each Method

Batch brewing requires smaller-scale equipment such as a single large vessel or vat, a heating element, and filtration systems designed to handle discrete quantities of coffee or tea at one time. Continuous brewing involves more complex machinery, including an insulated tank with an integrated water inlet, a constant supply of hot water, and continuous filtering mechanisms to allow beverage extraction without interruption. Your choice between these methods depends on the volume of production and available space, with batch brewing suited for smaller operations and continuous systems ideal for high-demand environments.

Brewing Process Comparison

Batch brewing involves brewing coffee in separate, timed cycles where a fixed amount of water passes through the coffee grounds, resulting in distinct, consistent flavor profiles per batch. Continuous brewing uses a steady flow of water over coffee grounds, allowing for larger quantities but potentially less control over extraction uniformity and flavor precision. Understanding these brewing process differences helps you choose the method that best suits your volume needs and desired coffee quality.

Flavor Profiles and Consistency

Batch brewing offers distinct flavor profiles with each batch reflecting unique variations due to precise control over steeping time and temperature, enhancing complexity and depth. Continuous brewing provides consistent flavor and strength by maintaining a steady extraction process, ideal for large quantities requiring uniform taste. Your choice depends on whether you prioritize nuanced flavor diversity or reliable consistency in every cup.

Scalability and Production Volume

Batch brewing offers flexibility with smaller production volumes, ideal for specialty coffee shops focusing on quality and limited servings. Continuous brewing excels in scalability, enabling high-volume output suitable for large-scale operations, such as cafes and commercial settings requiring consistent supply. Production efficiency in continuous brewing reduces downtime between batches, supporting uninterrupted service during peak demand periods.

Cost and Resource Considerations

Batch brewing generally requires lower upfront investment and is ideal for small-scale production, making it cost-effective for businesses with limited budgets. Continuous brewing demands higher initial capital and operational resources but offers greater efficiency and reduced labor costs over time. Your choice between the two should consider production volume, budget constraints, and long-term resource management needs.

Pros and Cons of Each Method

Batch brewing offers precise control over flavor and quality, making it ideal for smaller volumes and specialty coffee, but it can be time-consuming and less efficient for large-scale production. Continuous brewing ensures a steady supply and higher efficiency for large volumes, yet it may sacrifice flavor consistency and freshness due to prolonged extraction times. Choosing between batch and continuous brewing depends on balancing product quality, volume needs, and operational efficiency.

Choosing the Right Brewing Method

Choosing the right brewing method depends on your production scale and flavor consistency preferences: batch brewing offers precise control over each brew, ideal for smaller quantities and diverse flavor profiles, while continuous brewing is suited for high-volume output with consistent taste, making it efficient for commercial settings. Your choice impacts your equipment needs, quality control, and operational efficiency, so consider the trade-offs between flexibility and scalability. Understanding the key differences helps optimize your coffee or tea production to meet demand and maintain desired flavor standards.

Batch brewing vs continuous brewing Infographic

libmatt.com

libmatt.com