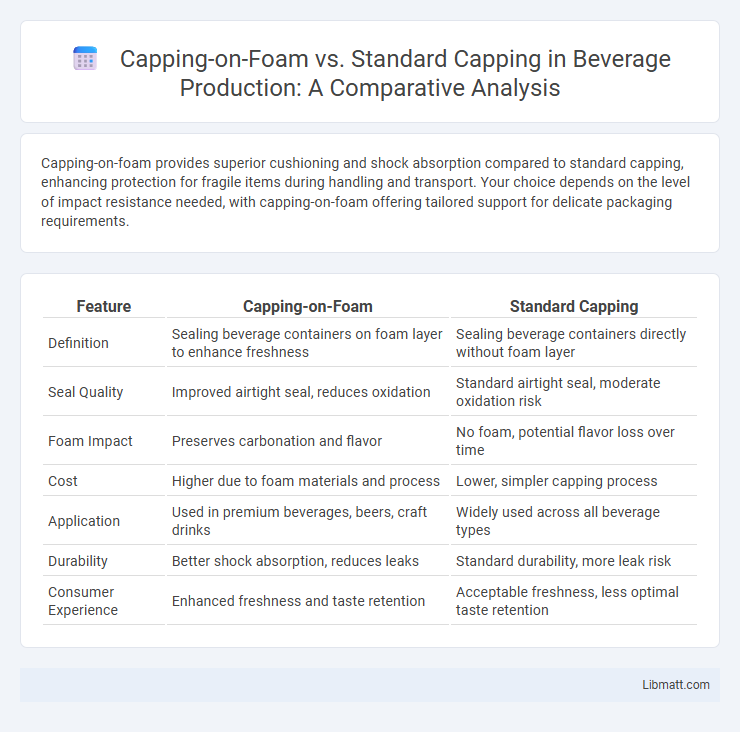

Capping-on-foam provides superior cushioning and shock absorption compared to standard capping, enhancing protection for fragile items during handling and transport. Your choice depends on the level of impact resistance needed, with capping-on-foam offering tailored support for delicate packaging requirements.

Table of Comparison

| Feature | Capping-on-Foam | Standard Capping |

|---|---|---|

| Definition | Sealing beverage containers on foam layer to enhance freshness | Sealing beverage containers directly without foam layer |

| Seal Quality | Improved airtight seal, reduces oxidation | Standard airtight seal, moderate oxidation risk |

| Foam Impact | Preserves carbonation and flavor | No foam, potential flavor loss over time |

| Cost | Higher due to foam materials and process | Lower, simpler capping process |

| Application | Used in premium beverages, beers, craft drinks | Widely used across all beverage types |

| Durability | Better shock absorption, reduces leaks | Standard durability, more leak risk |

| Consumer Experience | Enhanced freshness and taste retention | Acceptable freshness, less optimal taste retention |

Introduction to Capping-on-Foam and Standard Capping

Capping-on-foam involves adding a soft foam layer under the outermost material to enhance comfort and durability, commonly used in high-performance footwear and upholstery. Standard capping typically refers to rounding off edges or applying a protective covering without the added foam layer, prioritizing structural integrity and a clean finish. The foam layer in capping-on-foam provides improved cushioning and impact absorption compared to traditional standard capping techniques.

Understanding the Capping-on-Foam Process

Capping-on-foam involves applying a durable foam layer directly onto the material surface, providing enhanced cushioning and protection compared to standard capping methods that typically use thin film or tape. This process improves impact resistance, increases insulation properties, and extends the lifespan of your product by reducing damage from shocks and vibrations. Understanding the capping-on-foam technique ensures you select the appropriate protective solution tailored to your application's durability and comfort requirements.

How Standard Capping Works in Bottling

Standard capping in bottling involves placing a metal or plastic cap directly onto the bottle's threaded neck or finish, then applying pressure or torque to seal it securely. This method ensures a tight, tamper-evident closure that preserves product freshness and prevents contamination. The process relies on precision machinery to align and tighten caps uniformly, optimizing production speed and package integrity.

Key Differences Between Capping-on-Foam and Standard Capping

Capping-on-foam involves applying a thin foam layer beneath the capping material, enhancing insulation and shock absorption compared to standard capping, which uses a solid protective layer only. This foam layer improves comfort and durability by reducing impact stress and thermal transfer in various applications, such as flooring and packaging. Your choice between these two depends on the need for added cushioning and insulation versus traditional surface protection.

Impact on Product Quality and Shelf Life

Capping-on-foam technology enhances product quality by providing a superior seal that minimizes contamination and moisture ingress compared to standard capping methods. This advanced sealing technique significantly extends shelf life by maintaining optimal freshness and reducing oxidation in packaged goods. Studies demonstrate that products sealed with capping-on-foam retain sensory and nutritional attributes longer, thereby boosting consumer satisfaction and reducing spoilage rates.

Equipment Requirements and Cost Comparison

Capping-on-foam technology requires specialized dispensing equipment designed to accurately apply foam-based caps, often leading to higher initial capital investment compared to standard capping machines that use traditional physical lids. The foam capping equipment typically demands precision controls and maintenance to handle the unique properties of foam, while standard capping systems benefit from widespread availability and lower operational complexity, contributing to reduced overall costs. Choosing between these methods impacts Your budget and production efficiency depending on the scale and specific packaging needs of Your operation.

Efficiency and Production Line Considerations

Capping-on-foam technology significantly improves sealing efficiency by providing a tighter, more consistent seal compared to standard capping methods, reducing air leakage and enhancing product shelf life. It streamlines production lines by minimizing downtime and maintenance due to its simplified foam application process, leading to faster throughput rates. This method also reduces material waste and lowers operational costs by optimizing foam usage and decreasing cap rejection rates.

Advantages of Capping-on-Foam

Capping-on-foam offers superior cushioning and protection by integrating a foam layer beneath the cap, which reduces pressure points and enhances comfort compared to standard capping. This method improves insulation and durability, making it ideal for applications requiring enhanced thermal and impact resistance. Your products benefit from increased longevity and premium quality feel, elevating overall user experience.

Limitations and Challenges of Each Method

Capping-on-foam techniques face limitations such as inconsistent foam density and potential structural weaknesses, which may affect durability and performance. Standard capping methods often struggle with precise thickness control and increased material waste, leading to higher production costs and environmental impact. Your choice between these methods should consider these challenges in relation to your specific application requirements and quality standards.

Industry Trends and Future Outlook for Bottle Capping

Capping-on-foam technology is gaining traction in the beverage and pharmaceutical industries due to its enhanced sealing capabilities and improved product freshness compared to standard capping methods. Industry trends indicate a shift towards sustainable and automated capping solutions, with Capping-on-foam systems offering reduced plastic waste and compatibility with smart manufacturing processes. Future outlooks forecast increased adoption driven by consumer demand for eco-friendly packaging and the integration of IoT-enabled quality control in bottle capping operations.

Capping-on-foam vs standard capping Infographic

libmatt.com

libmatt.com