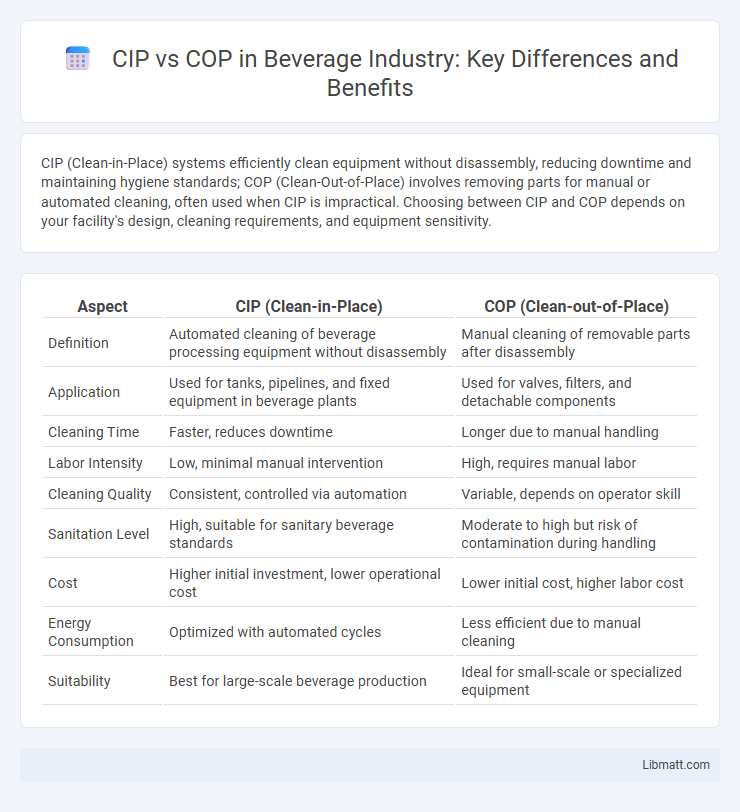

CIP (Clean-in-Place) systems efficiently clean equipment without disassembly, reducing downtime and maintaining hygiene standards; COP (Clean-Out-of-Place) involves removing parts for manual or automated cleaning, often used when CIP is impractical. Choosing between CIP and COP depends on your facility's design, cleaning requirements, and equipment sensitivity.

Table of Comparison

| Aspect | CIP (Clean-in-Place) | COP (Clean-out-of-Place) |

|---|---|---|

| Definition | Automated cleaning of beverage processing equipment without disassembly | Manual cleaning of removable parts after disassembly |

| Application | Used for tanks, pipelines, and fixed equipment in beverage plants | Used for valves, filters, and detachable components |

| Cleaning Time | Faster, reduces downtime | Longer due to manual handling |

| Labor Intensity | Low, minimal manual intervention | High, requires manual labor |

| Cleaning Quality | Consistent, controlled via automation | Variable, depends on operator skill |

| Sanitation Level | High, suitable for sanitary beverage standards | Moderate to high but risk of contamination during handling |

| Cost | Higher initial investment, lower operational cost | Lower initial cost, higher labor cost |

| Energy Consumption | Optimized with automated cycles | Less efficient due to manual cleaning |

| Suitability | Best for large-scale beverage production | Ideal for small-scale or specialized equipment |

Introduction to CIP and COP

CIP (Clean-in-Place) and COP (Clean-Out-of-Place) are essential cleaning methods used in food, pharmaceutical, and beverage industries to ensure hygiene and prevent contamination. CIP systems clean equipment internally without disassembly, optimizing efficiency and reducing downtime, while COP involves disassembling equipment for manual cleaning and inspection, suitable for complex components. Understanding the appropriate application of CIP and COP enhances operational safety and compliance with regulatory standards.

Definitions: What Are CIP and COP?

CIP (Cleaning In Place) is a method used to clean the interior surfaces of pipes, vessels, and equipment without disassembly, commonly applied in food, beverage, and pharmaceutical industries. COP (Clean Out of Place) involves removing equipment parts for manual cleaning and sanitation, suitable for components that cannot be effectively cleaned in place. Understanding these definitions helps you select the most efficient and compliant cleaning process for your operational needs.

Key Differences Between CIP and COP

CIP (Cleaning in Place) and COP (Clean out of Place) differ primarily in equipment handling and cleaning method. CIP involves cleaning equipment without disassembly, using automated cleaning systems ideal for complex machinery in industries like food and pharmaceuticals. COP requires manual disassembly and cleaning of components separately, offering thorough sanitation but demanding more labor and downtime, which can impact your maintenance efficiency.

How CIP Systems Work

CIP (Clean-in-Place) systems automate the cleaning of internal surfaces in process equipment using a series of chemical solutions, water, and rinses circulated through the system without disassembly. These systems use a combination of detergents, alkaline and acidic cleaners, and sanitizers at controlled temperatures, flow rates, and durations to effectively remove residues and contaminants. Your facility benefits from improved hygiene, reduced downtime, and consistent cleaning results by integrating CIP systems into production workflows.

How COP Systems Operate

COP systems operate by continuously moving refrigerant through a cycle of evaporation, compression, condensation, and expansion to transfer heat from a lower temperature source to a higher temperature sink. The compressor elevates the refrigerant's pressure and temperature, enabling efficient heat release during condensation, while evaporators absorb heat from the environment or usable waste sources. Understanding how your COP system operates can optimize energy use, reduce operational costs, and enhance overall system performance.

Advantages of CIP

CIP (Clean-in-Place) offers significant advantages over COP (Clean-out-of-Place) by enabling automated cleaning of equipment without disassembly, which reduces downtime and labor costs. It ensures consistent hygiene standards by delivering precise control over cleaning parameters such as temperature, pressure, and chemical concentration. Your facility benefits from improved safety and compliance with regulatory requirements due to minimized manual handling during the cleaning process.

Advantages of COP

COP (Coefficient of Performance) offers a more accurate measure of a heating or cooling system's efficiency by comparing useful heating or cooling output to the energy input. Higher COP values indicate greater energy efficiency, leading to reduced operational costs and lower environmental impact. This makes COP a preferred metric for evaluating heat pumps and HVAC systems, promoting sustainability and cost-effective energy use.

CIP vs COP: Applications in Industry

CIP (Clean-in-Place) and COP (Clean-out-of-Place) are essential industrial cleaning methods tailored for different operational needs. CIP systems are ideal for automated cleaning of pipelines and equipment in food, beverage, and pharmaceutical industries, ensuring hygiene without disassembly. COP is preferred for cleaning removable parts requiring manual handling, offering flexibility for components that cannot be cleaned in situ. Your choice depends on equipment design and hygiene standards.

Choosing Between CIP and COP: Key Factors

Choosing between CIP (Clean-in-Place) and COP (Clean-Out-of-Place) hinges on factors such as equipment design, production volume, and hygiene requirements. CIP systems offer automated cleaning for fixed equipment, enhancing efficiency in continuous processes, while COP is preferred for portable or complex parts that require manual handling. Decision-makers prioritize operational downtime, cleaning validation, and resource availability to determine the most suitable method for maintaining sanitation standards.

Conclusion: CIP vs COP Comparison

CIP (Clean-In-Place) and COP (Clean-Out-of-Place) systems differ primarily in their application and efficiency, with CIP offering automated, in-situ cleaning ideal for complex machinery, reducing downtime and labor costs. COP requires disassembly and manual cleaning of equipment parts, making it suitable for smaller, simpler components but less efficient for large-scale operations. CIP provides superior consistency and hygiene control, making it the preferred choice in industries demanding stringent sanitation standards such as pharmaceuticals and food processing.

CIP vs COP Infographic

libmatt.com

libmatt.com