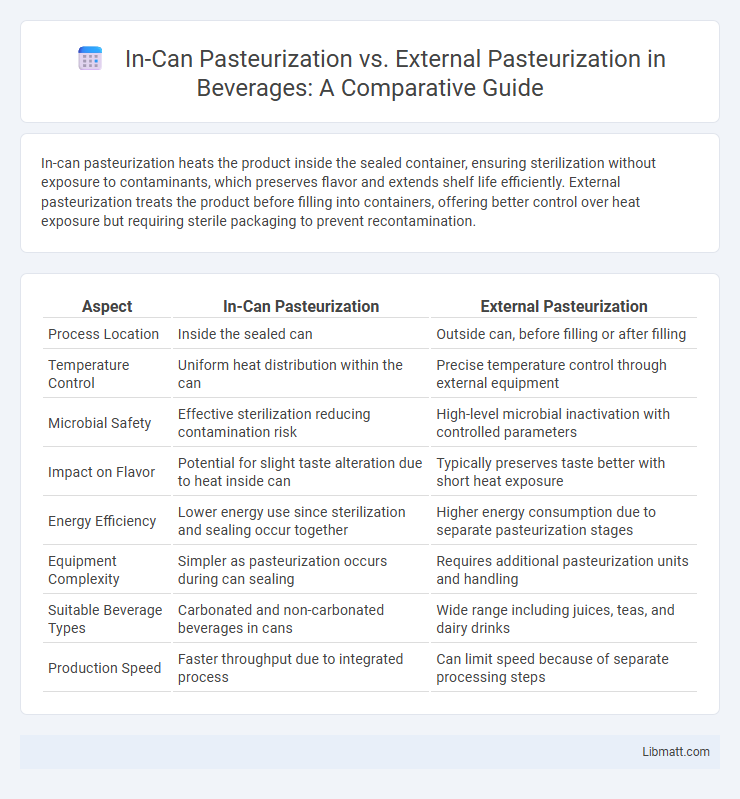

In-can pasteurization heats the product inside the sealed container, ensuring sterilization without exposure to contaminants, which preserves flavor and extends shelf life efficiently. External pasteurization treats the product before filling into containers, offering better control over heat exposure but requiring sterile packaging to prevent recontamination.

Table of Comparison

| Aspect | In-Can Pasteurization | External Pasteurization |

|---|---|---|

| Process Location | Inside the sealed can | Outside can, before filling or after filling |

| Temperature Control | Uniform heat distribution within the can | Precise temperature control through external equipment |

| Microbial Safety | Effective sterilization reducing contamination risk | High-level microbial inactivation with controlled parameters |

| Impact on Flavor | Potential for slight taste alteration due to heat inside can | Typically preserves taste better with short heat exposure |

| Energy Efficiency | Lower energy use since sterilization and sealing occur together | Higher energy consumption due to separate pasteurization stages |

| Equipment Complexity | Simpler as pasteurization occurs during can sealing | Requires additional pasteurization units and handling |

| Suitable Beverage Types | Carbonated and non-carbonated beverages in cans | Wide range including juices, teas, and dairy drinks |

| Production Speed | Faster throughput due to integrated process | Can limit speed because of separate processing steps |

Introduction to Pasteurization in Beverage Processing

In-can pasteurization involves heating beverages inside sealed cans, ensuring precise temperature control and reduced contamination risk during pasteurization. External pasteurization heats the beverage before packaging, allowing for continuous flow processing but increasing exposure to potential contaminants. You can enhance shelf life and safety by selecting the appropriate method based on processing scale and product sensitivity.

What is In-Can Pasteurization?

In-can pasteurization is a heat treatment process where food or beverages are sterilized directly inside the sealed container, eliminating the risk of post-pasteurization contamination. This method ensures product safety and extends shelf life by applying controlled heat within the can, preserving quality and flavor. Your choice of in-can pasteurization enhances product sterility and offers efficient processing compared to external pasteurization methods.

Understanding External Pasteurization Methods

External pasteurization methods involve heating products outside their final containers, allowing precise temperature control and uniform heat distribution, which ensures effective microbial reduction. Common techniques include steam-injection, hot-water, and hot-air pasteurization, each optimized for different food types and processing speeds. Understanding these methods helps you select the most efficient pasteurization process for preserving quality while ensuring food safety.

Key Differences Between In-Can and External Pasteurization

In-can pasteurization involves heating the product inside its sealed can, ensuring minimal contamination risk and preserving product integrity through uniform heat distribution. External pasteurization heats the product before packaging, allowing greater control over processing parameters but requiring strict aseptic packaging to prevent contamination. Your choice between these methods depends on factors like product type, desired shelf life, and production scale.

Impact on Product Quality and Flavor

In-can pasteurization preserves product quality by minimizing exposure to oxygen and contaminants, ensuring a fresher flavor and extended shelf life. External pasteurization may cause slight flavor alterations due to increased heat exposure and handling, potentially impacting sensory attributes. Your choice between these methods should consider the desired balance between flavor retention and processing efficiency.

Energy Efficiency and Operational Costs Comparison

In-can pasteurization consumes less energy by heating products directly inside their containers, reducing heat loss and shortening processing times compared to external pasteurization methods that heat products before filling. Operational costs for in-can pasteurization are typically lower because it requires less equipment and maintenance, minimizing labor and utility expenses. Your choice between these methods impacts overall efficiency, with in-can pasteurization generally offering higher energy savings and reduced operational costs.

Equipment Requirements and Production Scalability

In-can pasteurization requires specialized retorts designed to heat sealed cans uniformly, necessitating precise temperature control equipment, which can limit scalability due to batch processing constraints. External pasteurization employs continuous heat exchangers and sterilizers, enabling higher production rates with modular equipment that supports scalability in large-scale food processing plants. The choice between these methods depends on production volume demands and available infrastructure investment for equipment optimization.

Microbial Safety and Shelf Life Outcomes

In-can pasteurization provides enhanced microbial safety by eliminating contaminants directly within the sealed can, reducing post-processing contamination risks and extending shelf life more effectively than external pasteurization. External pasteurization often exposes products to potential recontamination during packaging, which can compromise microbial safety and shorten shelf life. Your choice between these methods impacts product stability, with in-can pasteurization generally offering superior protection for long-term storage.

Industry Trends and Preferred Applications

In-can pasteurization is increasingly favored in the beverage and canned food industries due to its efficiency in heat treatment within sealed containers, reducing contamination risks and preserving freshness. External pasteurization, commonly used in dairy and liquid products, provides precise temperature control and is ideal for products sensitive to heat exposure or requiring extended shelf life. Industry trends show a growing preference for in-can pasteurization in high-volume production lines, while external pasteurization remains preferred for premium and heat-sensitive products demanding stringent quality standards.

Conclusion: Choosing the Right Pasteurization Method

Choosing the right pasteurization method depends on product type, processing volume, and desired shelf life; in-can pasteurization offers sealed, contamination-free treatment directly inside the packaging, ideal for ready-to-eat foods and low-volume batches. External pasteurization provides greater flexibility and uniform heat distribution for liquids and bulk products, supporting higher throughput and consistent quality control. Analyzing cost, equipment complexity, and product sensitivity ensures optimal selection between in-can and external pasteurization techniques.

In-can pasteurization vs external pasteurization Infographic

libmatt.com

libmatt.com