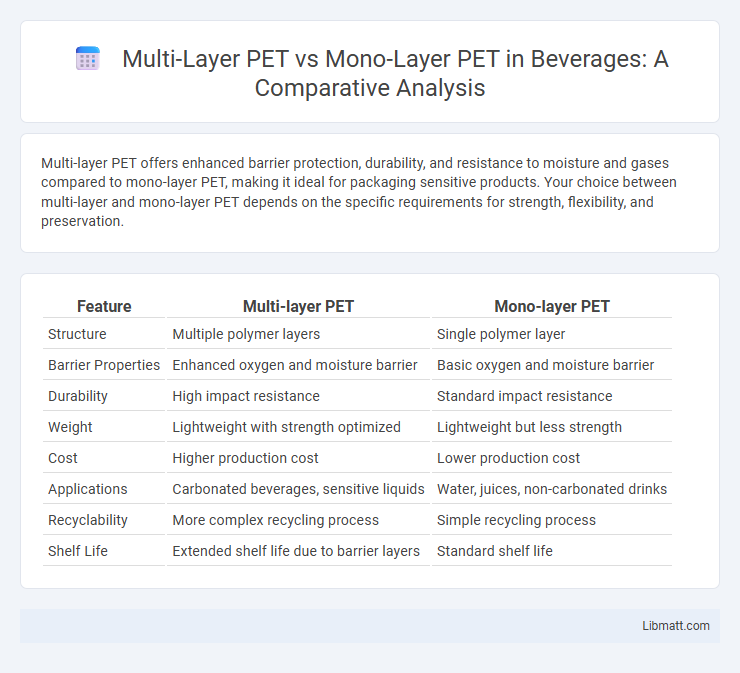

Multi-layer PET offers enhanced barrier protection, durability, and resistance to moisture and gases compared to mono-layer PET, making it ideal for packaging sensitive products. Your choice between multi-layer and mono-layer PET depends on the specific requirements for strength, flexibility, and preservation.

Table of Comparison

| Feature | Multi-layer PET | Mono-layer PET |

|---|---|---|

| Structure | Multiple polymer layers | Single polymer layer |

| Barrier Properties | Enhanced oxygen and moisture barrier | Basic oxygen and moisture barrier |

| Durability | High impact resistance | Standard impact resistance |

| Weight | Lightweight with strength optimized | Lightweight but less strength |

| Cost | Higher production cost | Lower production cost |

| Applications | Carbonated beverages, sensitive liquids | Water, juices, non-carbonated drinks |

| Recyclability | More complex recycling process | Simple recycling process |

| Shelf Life | Extended shelf life due to barrier layers | Standard shelf life |

Introduction to PET Packaging: Mono-layer vs Multi-layer

Mono-layer PET packaging consists of a single polyethylene terephthalate layer offering basic protection and transparency, commonly used for lightweight products. Multi-layer PET packaging combines multiple PET layers with other materials to enhance barrier properties, strength, and durability, ideal for preserving sensitive goods. Your choice depends on product requirements, balancing factors like shelf life, protection, and cost efficiency.

Material Composition: Understanding Mono-layer PET

Mono-layer PET consists of a single, homogeneous layer of polyethylene terephthalate, offering consistent material strength and clarity. This composition provides excellent moisture and gas barrier properties, making it ideal for packaging applications where uniformity and recyclability are priorities. Your choice of mono-layer PET ensures easier processing and improved compatibility with recycling streams compared to multi-layer PET alternatives.

Material Composition: Exploring Multi-layer PET

Multi-layer PET consists of several bonded layers combining different polymers such as polyethylene terephthalate (PET) with barrier materials like ethylene vinyl alcohol (EVOH) or nylon to enhance strength, oxygen, and moisture resistance. This composite structure provides superior durability and extended shelf life for food and beverage packaging compared to mono-layer PET, which is made solely from a single PET layer. Your choice of multi-layer PET ensures improved protection and performance in demanding applications requiring enhanced material properties.

Barrier Properties: Moisture and Gas Protection

Multi-layer PET films exhibit superior barrier properties compared to mono-layer PET, effectively enhancing protection against moisture and gas permeation. The incorporation of multiple layers, often including ethylene vinyl alcohol (EVOH) or other specialized barrier resins, significantly reduces oxygen and water vapor transmission rates. This advanced structure extends product shelf life in packaging applications by maintaining product freshness and preventing contamination.

Mechanical Strength and Durability

Multi-layer PET offers superior mechanical strength and durability compared to mono-layer PET due to its composite structure, which enhances resistance to impact, punctures, and environmental stress. The multiple layers act synergistically to provide improved barrier properties and structural integrity, making it ideal for packaging applications requiring extended shelf life and protection. Mono-layer PET, while cost-effective, tends to have lower tensile strength and less resistance to wear, limiting its use in high-stress or high-durability contexts.

Sustainability and Recycling Challenges

Multi-layer PET packaging enhances barrier properties and durability but poses significant sustainability and recycling challenges due to the difficulty in separating layers made from different polymers. Mono-layer PET is more amenable to recycling processes as it consists of a single polymer type, enabling higher material recovery rates and reduced contamination in recycling streams. Advances in recycling technology are needed to efficiently process multi-layer PET, aiming to improve circularity while maintaining the environmental benefits of PET use.

Cost Comparison and Economic Implications

Multi-layer PET films typically incur higher production costs than mono-layer PET due to their complex manufacturing processes involving multiple polymer layers for enhanced barrier properties. Your decision to invest in multi-layer PET can lead to long-term economic benefits by reducing product spoilage, extending shelf life, and improving durability, which may outweigh the initial expense. Mono-layer PET offers a more cost-effective option for applications with less stringent barrier requirements, making it a viable choice when budget constraints are a primary concern.

Common Applications in Food and Beverage Packaging

Multi-layer PET offers superior barrier properties against oxygen, moisture, and UV light, making it ideal for packaging sensitive food and beverage products like juices, dairy, and ready-to-eat meals. Mono-layer PET, while more cost-effective, is commonly used for packaging that requires moderate protection, such as water bottles and soft drink containers. Your choice between multi-layer and mono-layer PET depends on the shelf life requirements and sensitivity of the packaged product.

Regulatory Standards and Industry Requirements

Multi-layer PET films comply with stringent FDA and EU food contact regulations, offering enhanced barrier properties crucial for pharmaceutical and food packaging industries. Mono-layer PET films meet basic regulatory standards but lack the advanced chemical resistance and oxygen barrier performance required by high-demand applications. Industry requirements increasingly favor multi-layer PET for sustainable, high-performance packaging solutions that maintain product integrity and extend shelf life under regulatory scrutiny.

Future Trends in PET Packaging Technologies

Multi-layer PET packaging offers enhanced barrier properties, moisture resistance, and mechanical strength compared to mono-layer PET, making it ideal for preserving food and pharmaceutical products. Future trends emphasize the development of recyclable and bio-based multi-layer PET structures to address environmental concerns while maintaining performance. You can expect advancements in smart packaging integration within multi-layer PET to improve functionality and consumer interaction.

Multi-layer PET vs mono-layer PET Infographic

libmatt.com

libmatt.com