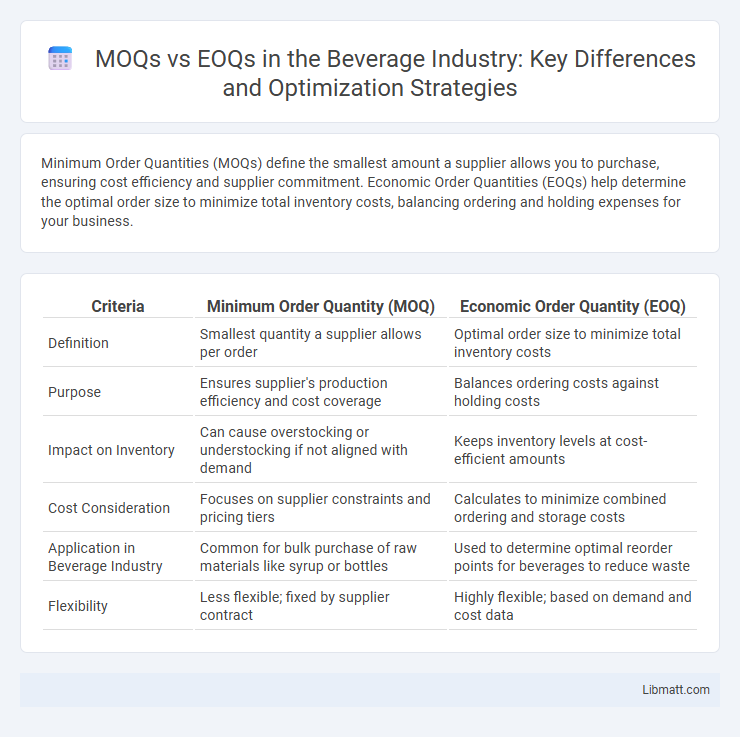

Minimum Order Quantities (MOQs) define the smallest amount a supplier allows you to purchase, ensuring cost efficiency and supplier commitment. Economic Order Quantities (EOQs) help determine the optimal order size to minimize total inventory costs, balancing ordering and holding expenses for your business.

Table of Comparison

| Criteria | Minimum Order Quantity (MOQ) | Economic Order Quantity (EOQ) |

|---|---|---|

| Definition | Smallest quantity a supplier allows per order | Optimal order size to minimize total inventory costs |

| Purpose | Ensures supplier's production efficiency and cost coverage | Balances ordering costs against holding costs |

| Impact on Inventory | Can cause overstocking or understocking if not aligned with demand | Keeps inventory levels at cost-efficient amounts |

| Cost Consideration | Focuses on supplier constraints and pricing tiers | Calculates to minimize combined ordering and storage costs |

| Application in Beverage Industry | Common for bulk purchase of raw materials like syrup or bottles | Used to determine optimal reorder points for beverages to reduce waste |

| Flexibility | Less flexible; fixed by supplier contract | Highly flexible; based on demand and cost data |

Introduction to MOQs and EOQs

Minimum Order Quantities (MOQs) define the smallest amount of stock a supplier allows you to purchase, ensuring cost efficiency and supplier viability. Economic Order Quantities (EOQs) calculate the optimal order size that minimizes total inventory costs, balancing ordering and holding expenses. Understanding MOQs and EOQs helps your business optimize inventory management and reduce overall supply chain costs.

Defining Minimum Order Quantity (MOQ)

Minimum Order Quantity (MOQ) refers to the smallest amount of a product that a supplier is willing to sell to a buyer in a single order, ensuring cost-effectiveness and efficient production processes. MOQs help businesses manage inventory levels by preventing understocking while aligning with supplier requirements for bulk purchasing. Understanding your MOQ is crucial for optimizing supply chain operations and negotiating better terms with suppliers.

Understanding Economic Order Quantity (EOQ)

Economic Order Quantity (EOQ) is a critical inventory management metric that determines the optimal order quantity minimizing total ordering and holding costs. EOQ balances demand rate, ordering costs, and carrying costs to reduce excess inventory and stockouts, ensuring efficient supply chain operations. Understanding EOQ allows your business to optimize purchase size, improve cash flow, and maintain steady inventory levels.

Key Differences Between MOQs and EOQs

Minimum Order Quantities (MOQs) refer to the smallest amount of a product a supplier is willing to sell, ensuring cost efficiency and inventory control, whereas Economic Order Quantities (EOQs) represent the optimal order size that minimizes total inventory costs, including ordering and holding expenses. MOQs are supplier-driven constraints impacting your sourcing strategy, while EOQs are internally calculated based on demand forecasts and inventory carrying costs to balance ordering frequency with storage efficiency. Understanding the key differences between MOQs and EOQs enables precise inventory management and cost optimization in your supply chain operations.

Advantages of Implementing MOQs

Implementing Minimum Order Quantities (MOQs) helps reduce ordering frequency and lowers overall procurement costs by leveraging bulk purchasing discounts. MOQs enable better inventory management by ensuring stock levels meet supplier requirements, minimizing stockouts and production delays. Your business benefits from improved cash flow predictability and stronger supplier relationships through consistent order sizes.

Benefits of Using EOQs for Inventory Management

EOQs (Economic Order Quantities) optimize your inventory levels by minimizing total ordering and holding costs, leading to efficient cash flow management and reduced stockouts. Implementing EOQs helps balance order frequency and quantity, ensuring your business maintains adequate stock without overstocking, which improves storage utilization. Precise EOQ calculations enable data-driven decisions, enhancing forecasting accuracy and streamlining supply chain operations.

Factors Influencing MOQ and EOQ Decisions

Factors influencing Minimum Order Quantity (MOQ) and Economic Order Quantity (EOQ) decisions include supplier constraints, storage capacity, demand variability, and cost considerations such as ordering, holding, and stockout costs. MOQ is often set by the supplier based on production batch sizes and minimum profitability thresholds, while EOQ aims to minimize total inventory costs by balancing ordering and holding expenses. Your inventory management strategy must account for lead times, purchase price discounts, and sales forecasts to optimize both MOQ and EOQ effectively.

Impact of MOQs vs EOQs on Supply Chain Efficiency

Minimum Order Quantities (MOQs) determine the smallest amount a supplier will accept, often leading to larger inventory holdings and increased carrying costs, which can reduce supply chain flexibility. Economic Order Quantities (EOQs) optimize order size to minimize total inventory costs, balancing ordering and holding expenses to enhance operational efficiency. Efficient management of MOQs and EOQs directly influences supply chain responsiveness, cost control, and inventory turnover rates.

Choosing the Right Strategy: MOQ or EOQ?

Choosing between Minimum Order Quantity (MOQ) and Economic Order Quantity (EOQ) involves balancing inventory costs and demand patterns. MOQs prioritize supplier requirements and bulk purchasing discounts, while EOQs focus on minimizing total inventory costs by calculating the optimal order size based on holding and ordering expenses. Businesses should analyze product demand variability, storage capacity, and cash flow to determine the most cost-effective ordering strategy.

Best Practices for Managing MOQs and EOQs

Effective management of Minimum Order Quantities (MOQs) and Economic Order Quantities (EOQs) involves accurately forecasting demand to balance inventory costs and avoid overstocking. Utilizing inventory management software that integrates real-time sales data enhances precision in setting MOQs aligned with supplier requirements and EOQs optimized for cost efficiency. Regularly reviewing and adjusting MOQs and EOQs based on market trends and supply chain dynamics ensures agility and reduces cash flow constraints.

MOQs vs EOQs Infographic

libmatt.com

libmatt.com