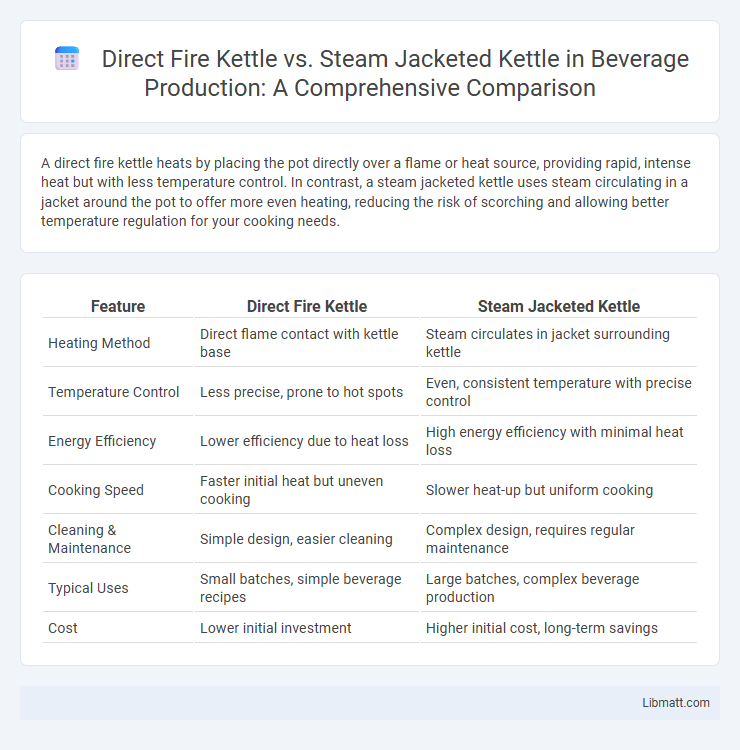

A direct fire kettle heats by placing the pot directly over a flame or heat source, providing rapid, intense heat but with less temperature control. In contrast, a steam jacketed kettle uses steam circulating in a jacket around the pot to offer more even heating, reducing the risk of scorching and allowing better temperature regulation for your cooking needs.

Table of Comparison

| Feature | Direct Fire Kettle | Steam Jacketed Kettle |

|---|---|---|

| Heating Method | Direct flame contact with kettle base | Steam circulates in jacket surrounding kettle |

| Temperature Control | Less precise, prone to hot spots | Even, consistent temperature with precise control |

| Energy Efficiency | Lower efficiency due to heat loss | High energy efficiency with minimal heat loss |

| Cooking Speed | Faster initial heat but uneven cooking | Slower heat-up but uniform cooking |

| Cleaning & Maintenance | Simple design, easier cleaning | Complex design, requires regular maintenance |

| Typical Uses | Small batches, simple beverage recipes | Large batches, complex beverage production |

| Cost | Lower initial investment | Higher initial cost, long-term savings |

Introduction to Kettle Heating Methods

Direct fire kettles utilize an open flame beneath the vessel to heat contents quickly through direct contact, offering fast and intense heat ideal for high-volume cooking. Steam jacketed kettles surround the cooking vessel with a steam-filled jacket, providing even, consistent heat that reduces scorching and improves temperature control. Understanding these heating methods helps you choose the best kettle based on cooking volume, heat distribution, and energy efficiency needs.

What is a Direct Fire Kettle?

A Direct Fire Kettle is a type of cooking vessel heated directly by an open flame beneath the kettle, allowing rapid temperature increases for boiling or simmering large batches of food. This kettle is commonly used in commercial kitchens and food processing where fast, intense heat application is needed for soups, sauces, or stews. Unlike steam jacketed kettles, direct fire kettles provide less precise temperature control but excel in applications requiring quick heat transfer and higher temperatures.

What is a Steam Jacketed Kettle?

A steam jacketed kettle is a large cooking vessel designed with a double-walled construction where steam circulates in the jacket surrounding the inner pot, providing even and efficient heat distribution for cooking soups, sauces, and other liquid-based foods. This method prevents scorching, promotes faster heating, and maintains consistent temperature control compared to direct fire kettles that apply heat directly to the pot's surface. Your kitchen operations will benefit from the energy efficiency and precise temperature management of steam jacketed kettles, especially in commercial food preparation environments.

Key Differences in Heating Technology

Direct fire kettles use an open flame beneath the vessel, providing rapid heat transfer but less precise temperature control, making them ideal for high-volume cooking where quick heating is essential. Steam jacketed kettles, on the other hand, employ steam circulated within a double-walled jacket surrounding the cooking chamber, ensuring even heat distribution and consistent temperature regulation for delicate or temperature-sensitive recipes. Your choice depends on the importance of heating precision versus speed, with steam jackets offering superior control and direct fire delivering faster, more intense heat.

Energy Efficiency Comparison

Direct fire kettles utilize combustion gases to heat the kettle surface, resulting in faster heat transfer but lower energy efficiency due to heat loss and uneven temperature distribution. Steam jacketed kettles offer superior energy efficiency by using steam circulated within a double-walled jacket, providing consistent, controllable heat with minimal energy waste. Overall, steam jacketed kettles reduce fuel consumption and operational costs, making them a more energy-efficient choice for large-scale cooking applications.

Impact on Food Quality and Consistency

Direct fire kettles heat food through direct flame contact, often causing hot spots that can lead to uneven cooking and potential scorching, negatively affecting food quality and consistency. Steam jacketed kettles provide uniform heating through steam circulation in the jacket surrounding the cooking vessel, ensuring even temperature distribution and consistent cooking results. This method preserves flavor and texture better, making steam jacketed kettles ideal for maintaining high-quality and consistent food products in commercial kitchens.

Safety Features and Considerations

Direct fire kettles pose higher safety risks due to open flames and uneven heat distribution, increasing the chance of burns or fires. Steam jacketed kettles feature enclosed steam compartments that provide consistent heat while minimizing exposure to open flames, enhancing operator safety. Your choice should prioritize models with built-in pressure relief valves, secure lids, and automatic shut-off systems to ensure safe operation.

Cleaning and Maintenance Requirements

Direct fire kettles demand more frequent and intensive cleaning due to soot buildup and residue on the heating surfaces, which can impact efficiency and safety. Steam jacketed kettles offer easier maintenance as the indirect heat prevents food from burning onto the kettle, reducing cleaning intervals and effort. You will find steam jacketed kettles typically require less downtime for cleaning, making them ideal for busy commercial kitchens where hygiene and operational efficiency are priorities.

Cost Analysis: Initial and Operational Expenses

Direct fire kettles generally have a lower initial cost compared to steam jacketed kettles due to simpler construction and fuel requirements. Operational expenses for direct fire kettles can be higher over time because they often use natural gas or propane less efficiently, leading to increased fuel consumption. Your choice depends on balancing upfront budget constraints against long-term energy savings and maintenance needs.

Choosing the Right Kettle for Your Kitchen

Selecting the right kettle for your kitchen depends on cooking volume and heat control preferences; direct fire kettles offer rapid heating through direct flame contact, ideal for small batches and high-temperature cooking. Steam jacketed kettles provide even heat distribution and precise temperature control by encasing the kettle in a steam jacket, making them suitable for large-scale production and delicate recipes. Consider factors such as energy efficiency, maintenance requirements, and available kitchen space to optimize cooking performance and operational costs.

Direct fire kettle vs steam jacketed kettle Infographic

libmatt.com

libmatt.com