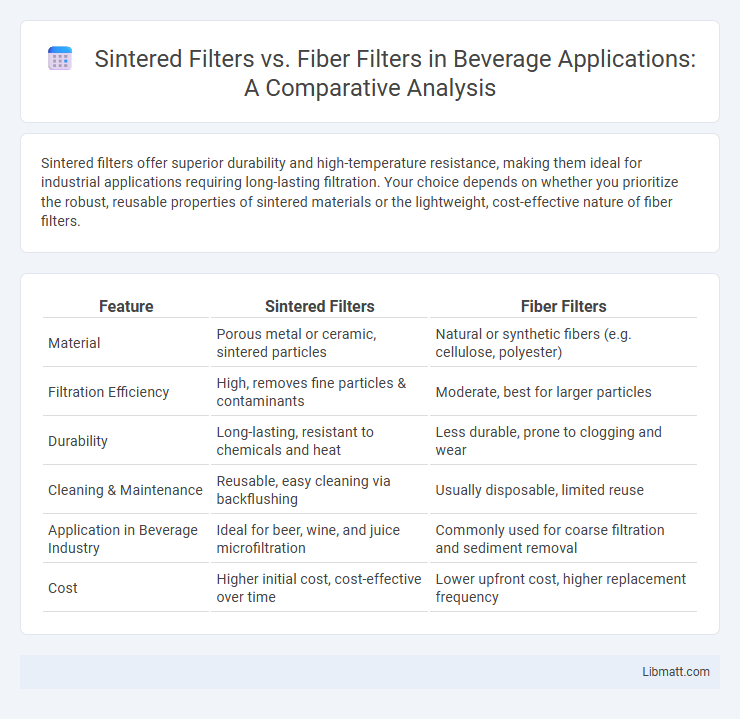

Sintered filters offer superior durability and high-temperature resistance, making them ideal for industrial applications requiring long-lasting filtration. Your choice depends on whether you prioritize the robust, reusable properties of sintered materials or the lightweight, cost-effective nature of fiber filters.

Table of Comparison

| Feature | Sintered Filters | Fiber Filters |

|---|---|---|

| Material | Porous metal or ceramic, sintered particles | Natural or synthetic fibers (e.g. cellulose, polyester) |

| Filtration Efficiency | High, removes fine particles & contaminants | Moderate, best for larger particles |

| Durability | Long-lasting, resistant to chemicals and heat | Less durable, prone to clogging and wear |

| Cleaning & Maintenance | Reusable, easy cleaning via backflushing | Usually disposable, limited reuse |

| Application in Beverage Industry | Ideal for beer, wine, and juice microfiltration | Commonly used for coarse filtration and sediment removal |

| Cost | Higher initial cost, cost-effective over time | Lower upfront cost, higher replacement frequency |

Introduction to Sintered Filters and Fiber Filters

Sintered filters are composed of metal powders fused together through a heat process, offering exceptional durability and high-temperature resistance for industrial filtration. Fiber filters utilize woven or non-woven fibers to trap particles, providing flexibility and effective filtration for applications requiring fine particulate removal. You can choose between sintered filters for robustness or fiber filters for tailored filtration efficiency based on your specific operational needs.

Material Composition and Construction

Sintered filters consist of metal powders such as stainless steel, bronze, or titanium fused under heat and pressure to form a rigid, porous structure ideal for high-temperature and high-pressure applications. Fiber filters are made from woven or non-woven fibers like fiberglass, polypropylene, or cellulose, offering flexibility and fine particle filtration through their layered or pleated construction. The sintered design provides durability and chemical resistance, while fiber filters excel in lighter-duty applications with greater surface area for particulate capture.

Filtration Mechanisms Explained

Sintered filters operate through mechanical filtration where porous metal particles fuse to create a rigid structure, effectively trapping contaminants by size exclusion. Fiber filters rely on depth filtration, capturing particles within a matrix of intertwined fibers that generate surface adhesion and interception. Both methods optimize filtration efficiency but vary in durability, porosity, and resistance to high temperatures or chemicals.

Particle Retention Efficiency

Sintered filters exhibit superior particle retention efficiency due to their rigid, porous metal structure that effectively traps fine particles down to sub-micron sizes while maintaining high flow rates. Fiber filters rely on a dense web of fibers to capture particles, often resulting in lower efficiency for ultra-fine particulates and higher pressure drops. The durability and consistent pore size of sintered filters make them ideal for applications requiring precise, high-performance filtration and minimal particle breakthrough.

Flow Rate and Pressure Drop Comparison

Sintered filters provide higher flow rates and lower pressure drops compared to fiber filters due to their rigid, porous metal structure that allows for efficient fluid passage while maintaining durability. Fiber filters typically exhibit higher pressure drops because of their dense, layered fibers that trap smaller particles but restrict flow more significantly. You can optimize system performance by selecting sintered filters when maintaining high flow rates and low pressure drops is critical.

Chemical and Thermal Resistance

Sintered filters offer superior chemical and thermal resistance due to their robust metal matrix structure, enabling them to withstand high temperatures exceeding 500degC and aggressive chemical environments without degradation. Fiber filters, typically made from materials like fiberglass or synthetic fibers, have lower thermal resistance and can degrade or lose filtration efficiency when exposed to harsh chemicals or temperatures above 200degC. Your choice of filter should consider these performance differences to ensure optimal durability and reliability in demanding industrial applications.

Durability and Longevity

Sintered filters, made from compressed metal powders, offer superior durability and longer lifespan compared to fiber filters due to their high resistance to abrasion, heat, and chemical corrosion. Fiber filters, typically composed of synthetic or natural fibers, tend to degrade faster under harsh operating conditions and require more frequent replacements. The robust structure of sintered filters ensures consistent performance and cost-effectiveness in industrial applications demanding extended filter longevity.

Maintenance and Cleaning Requirements

Sintered filters require less frequent maintenance due to their durable construction, which allows for easier backflushing and resistance to clogging compared to fiber filters. Fiber filters often need more regular replacement or cleaning because they can trap finer particles, leading to faster accumulation and reduced airflow. Your choice between these filter types should consider the balance between maintenance effort and filtration efficiency based on your specific application needs.

Cost Analysis and Economic Considerations

Sintered filters typically have higher upfront costs due to advanced manufacturing processes and durable materials but offer longer lifespans and reduced maintenance expenses, resulting in lower total cost of ownership over time. Fiber filters are less expensive initially but often require frequent replacement and generate higher waste disposal costs, impacting long-term economic efficiency. Your choice should balance initial budget constraints with lifecycle costs to optimize filtration investment.

Ideal Applications for Each Filter Type

Sintered filters are ideal for high-temperature and high-pressure applications such as chemical processing, gas filtration, and hydraulic fluid filtration due to their durability and resistance to corrosion. Fiber filters excel in low-pressure environments, making them suitable for air purification, HVAC systems, and dust collection where lightweight, flexible filtration media are required. Your choice between sintered and fiber filters should be based on operational conditions and the specific contaminants you need to remove.

Sintered filters vs fiber filters Infographic

libmatt.com

libmatt.com