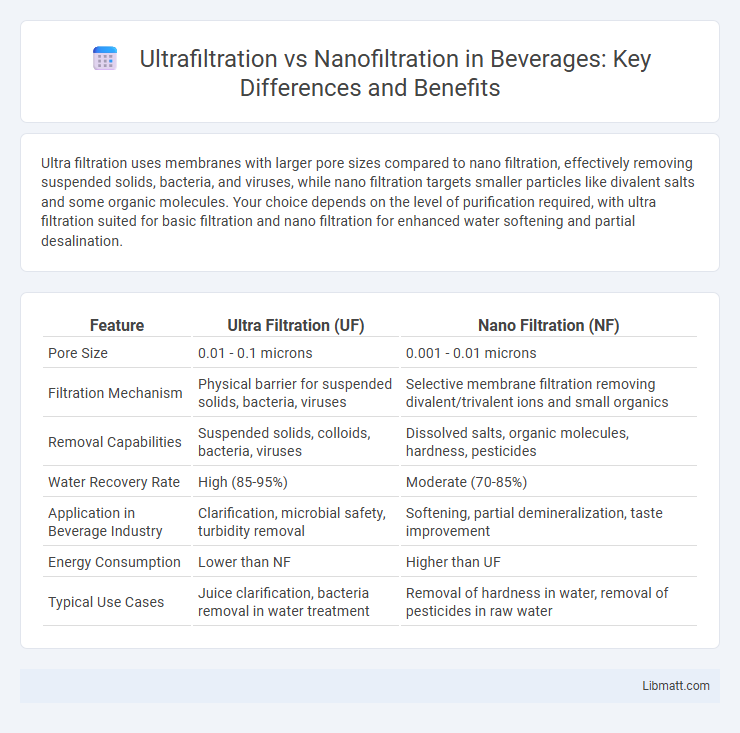

Ultra filtration uses membranes with larger pore sizes compared to nano filtration, effectively removing suspended solids, bacteria, and viruses, while nano filtration targets smaller particles like divalent salts and some organic molecules. Your choice depends on the level of purification required, with ultra filtration suited for basic filtration and nano filtration for enhanced water softening and partial desalination.

Table of Comparison

| Feature | Ultra Filtration (UF) | Nano Filtration (NF) |

|---|---|---|

| Pore Size | 0.01 - 0.1 microns | 0.001 - 0.01 microns |

| Filtration Mechanism | Physical barrier for suspended solids, bacteria, viruses | Selective membrane filtration removing divalent/trivalent ions and small organics |

| Removal Capabilities | Suspended solids, colloids, bacteria, viruses | Dissolved salts, organic molecules, hardness, pesticides |

| Water Recovery Rate | High (85-95%) | Moderate (70-85%) |

| Application in Beverage Industry | Clarification, microbial safety, turbidity removal | Softening, partial demineralization, taste improvement |

| Energy Consumption | Lower than NF | Higher than UF |

| Typical Use Cases | Juice clarification, bacteria removal in water treatment | Removal of hardness in water, removal of pesticides in raw water |

Introduction to Membrane Filtration Technologies

Membrane filtration technologies, including ultrafiltration and nanofiltration, utilize semi-permeable membranes to separate particles based on size and molecular weight. Ultrafiltration membranes typically filter particles in the range of 0.01 to 0.1 microns, effectively removing macromolecules, suspended solids, bacteria, and pathogens. Nanofiltration membranes have smaller pore sizes ranging from 1 to 10 nanometers, enabling selective removal of divalent salts, organic molecules, and larger monovalent ions while allowing smaller monovalent ions and water molecules to pass through.

Understanding Ultra Filtration: Principles and Applications

Ultra filtration operates on the principle of size exclusion, using semipermeable membranes with pore sizes typically between 0.01 to 0.1 microns to remove suspended solids, bacteria, and high molecular weight solutes from water and wastewater. Common applications include water purification, dairy processing, and pharmaceutical industries, where removal of macromolecules without affecting dissolved salts is essential. Ultra filtration offers a balance of high flux rates and selective separation, making it suitable for applications requiring microbial safety and turbidity reduction.

Nano Filtration Explained: Key Features and Uses

Nano filtration employs membranes with pore sizes between 1-10 nanometers, effectively removing divalent and larger ions while allowing monovalent ions to pass, making it ideal for water softening and partial desalination. Its high selectivity and lower energy requirements compared to reverse osmosis enable applications in beverage production, wastewater treatment, and pharmaceutical processes. Key features include moderate salt rejection, retention of essential minerals, and resistance to fouling, optimizing both water quality and operational efficiency.

Core Differences Between Ultra Filtration and Nano Filtration

Ultra filtration and nano filtration differ primarily in pore size, filtration capability, and pressure requirements, with ultra filtration removing particles between 0.01 to 0.1 microns and nano filtration filtering down to 0.001 microns, targeting smaller contaminants. Ultra filtration effectively removes bacteria, viruses, and suspended solids, whereas nano filtration additionally reduces divalent salts and organic molecules, offering more selective separation. Your choice between ultra filtration and nano filtration depends on the specific impurities you need to eliminate and the desired water quality.

Filtration Membrane Structure and Pore Size Comparison

Ultrafiltration membranes possess pore sizes typically ranging from 0.01 to 0.1 microns, designed to remove macromolecules, bacteria, and suspended solids. Nanofiltration membranes feature smaller pore sizes between 0.001 and 0.01 microns, allowing them to filter out divalent and larger monovalent ions while retaining essential minerals. The structural difference lies in ultrafiltration's thicker polymer layers providing coarse filtration, whereas nanofiltration involves thinner membranes with tighter molecular sieving capabilities.

Water Treatment Efficiency: UF vs. NF

Ultrafiltration (UF) removes particles between 0.01 to 0.1 microns, effectively eliminating bacteria, viruses, and suspended solids, making it ideal for pre-treatment and drinking water purification. Nanofiltration (NF) targets smaller molecules around 0.001 microns, offering superior removal of divalent salts, organic compounds, and some pesticides, enhancing water softening and color removal. Your choice depends on the required water treatment efficiency, with UF excelling in microbial safety and NF providing advanced contaminant reduction for higher water quality.

Removal Capabilities: Contaminants and Particles

Ultrafiltration membranes effectively remove particles ranging from 0.01 to 0.1 microns, including bacteria, viruses, and suspended solids, ensuring high water clarity and microbial safety. Nanofiltration membranes target smaller contaminants such as divalent and larger monovalent ions, organic molecules, and certain pesticides, offering partial removal of dissolved salts and improving taste and hardness. Understanding the specific contaminants in Your water source helps determine whether ultrafiltration or nanofiltration best suits Your purification needs.

Industrial Applications: Choosing UF or NF

Ultra filtration (UF) and nano filtration (NF) serve distinct roles in industrial water treatment, with UF primarily removing suspended solids, bacteria, and viruses, making it ideal for wastewater treatment, food and beverage processing, and pharmaceutical manufacturing. NF offers finer filtration by targeting divalent and larger monovalent ions, enabling effective softening, organic compound removal, and recovery of valuable components in chemical, textile, and dairy industries. Selecting UF or NF depends on required contaminant size, water quality goals, and process-specific impurity profiles to optimize operational efficiency and product quality.

Cost Analysis and Energy Consumption

Ultra filtration systems generally incur lower operational costs and consume less energy compared to nano filtration due to their larger pore size, which requires less pressure to filter contaminants. Nano filtration, while more expensive initially and in energy usage, offers higher filtration efficiency by removing smaller particles and certain dissolved substances, making it suitable for applications requiring finer purification. Your choice between the two should consider the balance between budget constraints and the specific water quality needs of the process.

Selecting the Right Filtration Method for Your Needs

Ultra filtration (UF) effectively removes suspended solids, bacteria, and large organic molecules, making it ideal for water purification and wastewater treatment. Nano filtration (NF) filters smaller particles, such as divalent ions, pesticides, and viruses, providing enhanced removal of contaminants and softening water with moderate energy consumption. Your choice between UF and NF depends on the specific contaminants you need to target and the quality requirements of your application.

Ultra filtration vs nano filtration Infographic

libmatt.com

libmatt.com