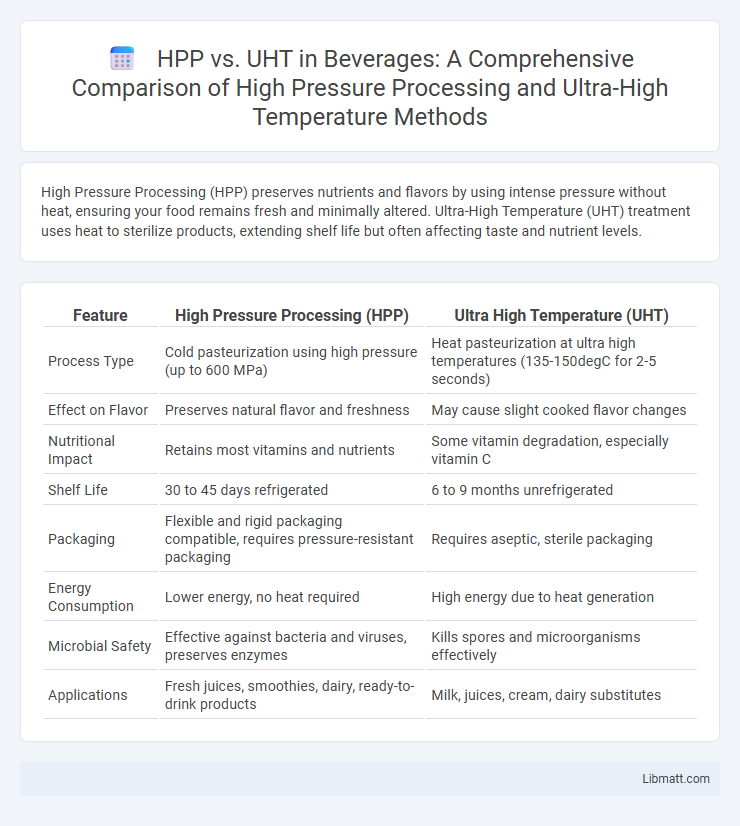

High Pressure Processing (HPP) preserves nutrients and flavors by using intense pressure without heat, ensuring your food remains fresh and minimally altered. Ultra-High Temperature (UHT) treatment uses heat to sterilize products, extending shelf life but often affecting taste and nutrient levels.

Table of Comparison

| Feature | High Pressure Processing (HPP) | Ultra High Temperature (UHT) |

|---|---|---|

| Process Type | Cold pasteurization using high pressure (up to 600 MPa) | Heat pasteurization at ultra high temperatures (135-150degC for 2-5 seconds) |

| Effect on Flavor | Preserves natural flavor and freshness | May cause slight cooked flavor changes |

| Nutritional Impact | Retains most vitamins and nutrients | Some vitamin degradation, especially vitamin C |

| Shelf Life | 30 to 45 days refrigerated | 6 to 9 months unrefrigerated |

| Packaging | Flexible and rigid packaging compatible, requires pressure-resistant packaging | Requires aseptic, sterile packaging |

| Energy Consumption | Lower energy, no heat required | High energy due to heat generation |

| Microbial Safety | Effective against bacteria and viruses, preserves enzymes | Kills spores and microorganisms effectively |

| Applications | Fresh juices, smoothies, dairy, ready-to-drink products | Milk, juices, cream, dairy substitutes |

Introduction to HPP and UHT Technologies

High Pressure Processing (HPP) and Ultra-High Temperature (UHT) processing are advanced food preservation technologies designed to extend shelf life while maintaining product quality. HPP uses intense cold water pressure up to 600 MPa to inactivate pathogens and spoilage microorganisms without heat, preserving nutritional and sensory attributes. In contrast, UHT employs rapid heating to temperatures above 135degC for a few seconds to achieve sterilization, enabling ambient storage but potentially affecting taste and nutrient profiles.

How HPP (High Pressure Processing) Works

High Pressure Processing (HPP) inactivates harmful microorganisms by applying extremely high pressure, typically between 300 and 600 MPa, uniformly around packaged food or beverages, without using heat. This method preserves the nutritional quality, flavor, and texture of products better than UHT (Ultra-High Temperature) processing, which relies on intense heat to sterilize by heating liquids to about 135-150degC for a few seconds. HPP extends shelf life while maintaining fresh-like qualities by targeting bacterial cell membranes and enzymes, resulting in safer, minimally processed food.

How UHT (Ultra-High Temperature) Processing Works

UHT (Ultra-High Temperature) processing heats liquid foods to temperatures between 135degC and 150degC for 2 to 5 seconds, effectively sterilizing the product by killing harmful microorganisms and spores. This rapid heating and cooling preserve the nutritional quality and extend shelf life without the need for refrigeration until opened. Your products benefit from longer storage periods and convenience while maintaining safety and taste through this precise thermal method.

Key Differences Between HPP and UHT

High Pressure Processing (HPP) uses intense pressure up to 600 MPa to inactivate pathogens and extend shelf life without heat, preserving the sensory and nutritional qualities of food. Ultra-High Temperature (UHT) treatment involves heating products to 135-150degC for a few seconds, effectively sterilizing them but often causing changes in flavor, texture, and nutrient loss. HPP is favored for fresh-like taste and raw food safety, while UHT is advantageous for ambient storage and long shelf stability.

Impact on Food Safety and Shelf Life

High Pressure Processing (HPP) preserves food safety by inactivating pathogens and spoilage microorganisms through intense pressure, maintaining nutrients and sensory qualities without heat exposure. Ultra-High Temperature (UHT) processing extends shelf life by sterilizing food at temperatures above 135degC, effectively destroying microbes but causing slight changes in taste and nutritional content. While UHT offers longer shelf stability at room temperature, HPP ensures fresher taste and higher nutritional retention with moderate shelf life extension under refrigeration.

Effects on Nutritional Value and Flavor

High-Pressure Processing (HPP) preserves the nutritional value of foods by inactivating pathogens without high heat, maintaining vitamins and antioxidants more effectively than Ultra-High Temperature (UHT) processing, which can degrade heat-sensitive nutrients. HPP retains the natural flavor and fresh taste of products, while UHT often imparts a cooked or slightly caramelized flavor due to intense heating. Selecting HPP can better protect your food's original nutritional profile and taste, enhancing overall quality.

Applications and Suitable Products for HPP

High Pressure Processing (HPP) is ideal for preserving fresh, ready-to-eat foods such as deli meats, juices, guacamole, and seafood by inactivating pathogens and extending shelf life without heat. Unlike UHT, which is suited for shelf-stable dairy and beverages subjected to high temperature sterilization, HPP maintains the sensory and nutritional quality of heat-sensitive products. Your choice of HPP is especially effective for products requiring minimal processing while ensuring food safety and freshness.

Applications and Suitable Products for UHT

UHT (Ultra-High Temperature) processing is ideal for products requiring long shelf life without refrigeration, such as milk, cream, and dairy-based beverages, as well as fruit juices and ready-to-drink soups. This method effectively eliminates microbial spores, making it suitable for aseptic packaging and distribution in retail environments where cold storage is limited. Your choice of UHT ensures convenience and extended durability for shelf-stable products favored in global supply chains and consumer markets.

Environmental and Energy Considerations

HPP (High Pressure Processing) significantly reduces energy consumption compared to UHT (Ultra-High Temperature) processing by using pressure instead of heat to preserve food, resulting in lower carbon emissions. UHT requires continuous high temperatures, leading to higher energy usage and environmental impact due to fossil fuel dependency in many processing plants. Your choice of HPP can support more sustainable food production with minimized energy use and a smaller carbon footprint.

Choosing Between HPP and UHT: Which is Better?

Choosing between High Pressure Processing (HPP) and Ultra-High Temperature (UHT) processing depends on product type and desired shelf life. HPP preserves nutrients, flavor, and texture by using cold pressure, extending freshness without heat damage, ideal for juices and deli meats. UHT uses rapid heating to extend shelf life up to six months without refrigeration, best suited for milk and cream products requiring long-term storage.

HPP vs UHT Infographic

libmatt.com

libmatt.com