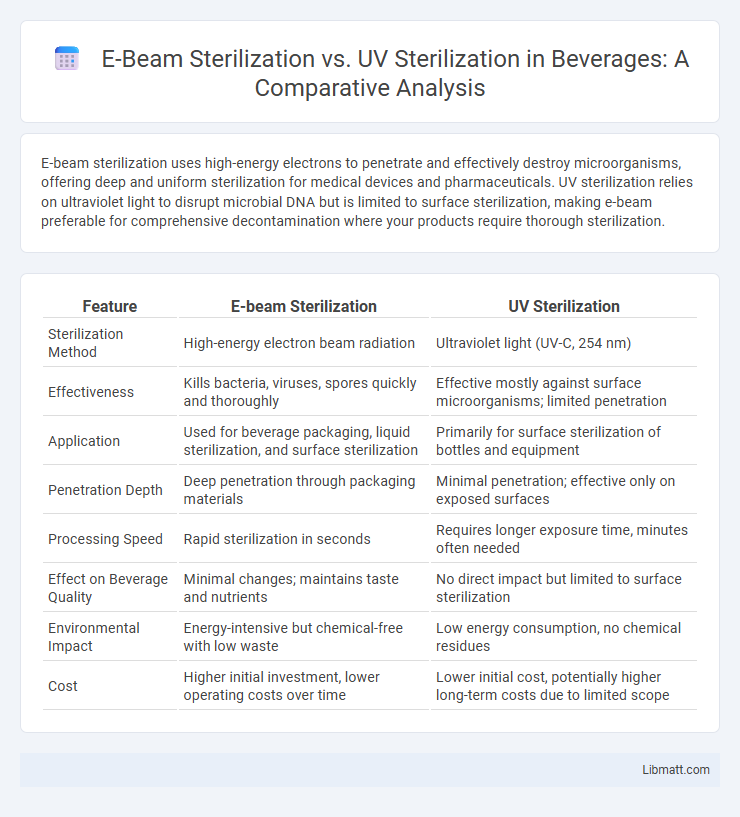

E-beam sterilization uses high-energy electrons to penetrate and effectively destroy microorganisms, offering deep and uniform sterilization for medical devices and pharmaceuticals. UV sterilization relies on ultraviolet light to disrupt microbial DNA but is limited to surface sterilization, making e-beam preferable for comprehensive decontamination where your products require thorough sterilization.

Table of Comparison

| Feature | E-beam Sterilization | UV Sterilization |

|---|---|---|

| Sterilization Method | High-energy electron beam radiation | Ultraviolet light (UV-C, 254 nm) |

| Effectiveness | Kills bacteria, viruses, spores quickly and thoroughly | Effective mostly against surface microorganisms; limited penetration |

| Application | Used for beverage packaging, liquid sterilization, and surface sterilization | Primarily for surface sterilization of bottles and equipment |

| Penetration Depth | Deep penetration through packaging materials | Minimal penetration; effective only on exposed surfaces |

| Processing Speed | Rapid sterilization in seconds | Requires longer exposure time, minutes often needed |

| Effect on Beverage Quality | Minimal changes; maintains taste and nutrients | No direct impact but limited to surface sterilization |

| Environmental Impact | Energy-intensive but chemical-free with low waste | Low energy consumption, no chemical residues |

| Cost | Higher initial investment, lower operating costs over time | Lower initial cost, potentially higher long-term costs due to limited scope |

Introduction to E-beam and UV Sterilization

E-beam sterilization employs high-energy electrons to disrupt microbial DNA, effectively eliminating pathogens in medical devices and pharmaceutical products with rapid and uniform penetration. UV sterilization utilizes ultraviolet light, primarily UV-C wavelengths, to inactivate microorganisms by damaging their nucleic acids, ideal for surface and air disinfection but with limited penetration depth. Both methods serve critical roles in sterilization protocols, with E-beam offering deeper material penetration while UV light provides a chemical-free, cost-effective solution for surface sterilization.

How E-beam Sterilization Works

E-beam sterilization uses high-energy electrons generated by an electron accelerator to penetrate products and disrupt the DNA of microorganisms, effectively eliminating bacteria and viruses. The process delivers precise doses of ionizing radiation, ensuring deep and uniform sterilization without the need for heat or chemicals. Your products benefit from rapid processing times and compatibility with heat-sensitive materials, making E-beam sterilization a versatile and efficient choice.

Mechanism of UV Sterilization

UV sterilization works by emitting short-wavelength ultraviolet light, typically UV-C, which penetrates microbial cells and disrupts their DNA or RNA, preventing replication and causing cell death. This photochemical reaction primarily targets the nucleic acids, leading to the formation of thymine dimers in DNA that inhibit transcription and replication processes. Unlike e-beam sterilization, which uses high-energy electrons to break molecular bonds directly, UV sterilization relies on light-induced genetic damage, making it effective for surface sterilization and air or water disinfection but less penetrating for dense or opaque materials.

Efficacy: E-beam vs UV Sterilization

E-beam sterilization delivers high-energy electrons that penetrate deeply, effectively eliminating a broad spectrum of microorganisms including bacteria, viruses, and spores, offering superior sterilization efficacy compared to UV sterilization. UV sterilization relies on ultraviolet light to disrupt microbial DNA but has limited penetration, reducing its effectiveness against shadowed or inaccessible surfaces and resistant spores. Your choice of sterilization method should consider the required penetration depth and microbial load to ensure optimal disinfection outcomes.

Material Compatibility and Penetration Depth

E-beam sterilization offers superior penetration depth compared to UV sterilization, effectively sterilizing dense and multilayered materials without compromising integrity. UV sterilization is generally limited to surface-level applications due to its shallow penetration, which can restrict its effectiveness on opaque or thick materials. Material compatibility for E-beam sterilization is broader, as it avoids heat and moisture damage, making it suitable for heat-sensitive polymers, while UV sterilization may degrade certain plastics and organic materials upon prolonged exposure.

Safety Considerations and Regulatory Compliance

E-beam sterilization offers deep penetration and is widely accepted by regulatory bodies such as the FDA and ISO for medical device sterilization, ensuring compliance with stringent safety standards. UV sterilization, limited to surface applications, poses potential risks of incomplete microbial inactivation and requires strict exposure controls to meet safety regulations. Both methods demand rigorous validation protocols and adherence to regulatory guidelines to guarantee product safety and effectiveness.

Processing Time and Throughput Comparison

E-beam sterilization offers rapid processing times, typically completing sterilization in seconds, making it ideal for high-throughput applications requiring fast turnaround. UV sterilization requires longer exposure durations, often minutes per cycle, limiting its efficiency for bulk or continuous processing. Your choice depends on the scale and speed of sterilization needed, with E-beam providing superior throughput for industrial-scale operations.

Environmental Impact and Sustainability

E-beam sterilization consumes less energy and produces no chemical waste, making it a more environmentally sustainable choice compared to UV sterilization, which requires frequent bulb replacements and generates mercury-containing waste. The high penetration power of E-beam allows sterilization of dense or packaged materials, reducing material waste and packaging needs. Choosing E-beam sterilization can enhance your facility's sustainability profile by minimizing hazardous waste and energy consumption.

Cost Analysis: E-beam vs UV Sterilization

E-beam sterilization incurs higher initial capital expenses due to advanced electron accelerator equipment but offers lower per-cycle costs for high-volume operations. UV sterilization involves lower upfront investment with relatively modest operational costs yet may require frequent lamp replacements and higher energy consumption for effective sterilization. Bulk processing efficiency and lower labor intensity make E-beam more cost-effective for industrial-scale sterilization compared to UV technology, which excels in small-scale or surface-level applications.

Choosing the Right Sterilization Method

E-beam sterilization offers deep penetration and rapid microbial inactivation, making it ideal for sterilizing thick or dense materials, while UV sterilization is limited to surface treatment and is most effective on smooth, transparent surfaces. When choosing the right sterilization method, factors such as material compatibility, sterilization depth, processing speed, and cost efficiency must be evaluated to ensure optimal microbial control. E-beam is preferred for high-throughput industrial applications requiring thorough sterilization, whereas UV is more suitable for surface sterilization of medical devices and air or water purification systems.

E-beam sterilization vs UV sterilization Infographic

libmatt.com

libmatt.com