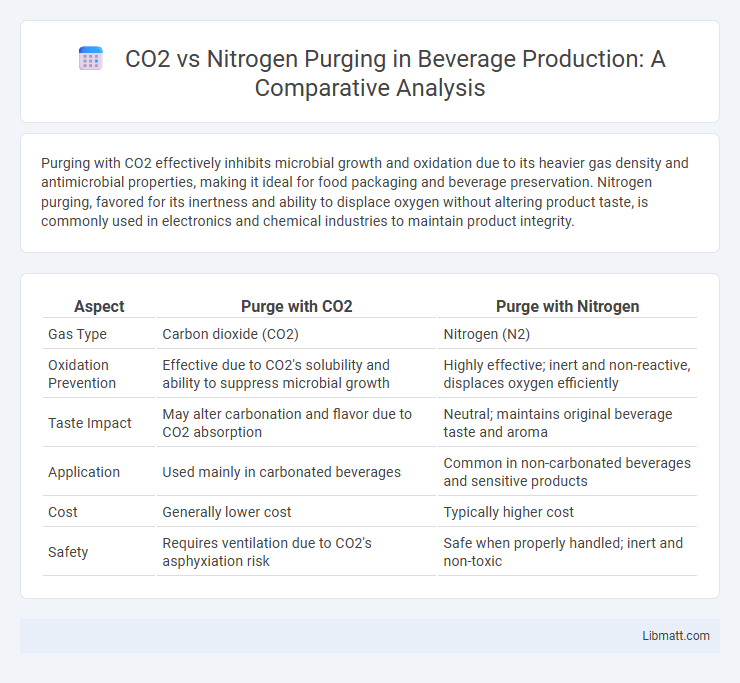

Purging with CO2 effectively inhibits microbial growth and oxidation due to its heavier gas density and antimicrobial properties, making it ideal for food packaging and beverage preservation. Nitrogen purging, favored for its inertness and ability to displace oxygen without altering product taste, is commonly used in electronics and chemical industries to maintain product integrity.

Table of Comparison

| Aspect | Purge with CO2 | Purge with Nitrogen |

|---|---|---|

| Gas Type | Carbon dioxide (CO2) | Nitrogen (N2) |

| Oxidation Prevention | Effective due to CO2's solubility and ability to suppress microbial growth | Highly effective; inert and non-reactive, displaces oxygen efficiently |

| Taste Impact | May alter carbonation and flavor due to CO2 absorption | Neutral; maintains original beverage taste and aroma |

| Application | Used mainly in carbonated beverages | Common in non-carbonated beverages and sensitive products |

| Cost | Generally lower cost | Typically higher cost |

| Safety | Requires ventilation due to CO2's asphyxiation risk | Safe when properly handled; inert and non-toxic |

Understanding Inert Gas Purging

Inert gas purging using CO2 versus nitrogen involves displacing oxygen and moisture to create a controlled atmosphere that prevents oxidation and contamination. Carbon dioxide offers a higher density than nitrogen, enabling more effective displacement of ambient air in confined spaces, while nitrogen provides a chemically inert and stable environment ideal for sensitive processes. Selecting the appropriate inert gas depends on factors such as gas solubility, cost, and specific industrial applications like food packaging or chemical manufacturing.

What is CO2 Purging?

CO2 purging involves replacing oxygen or other unwanted gases in a system or container with carbon dioxide to prevent oxidation, maintain freshness, or ensure safety during processing. Compared to nitrogen purging, CO2 offers antimicrobial properties and can be more cost-effective for certain applications in food and beverage industries. Understanding your system's requirements helps determine whether CO2 purging or nitrogen purging provides the optimal atmosphere control.

What is Nitrogen Purging?

Nitrogen purging involves displacing oxygen and contaminants from a system using nitrogen gas to prevent oxidation, moisture, and potential hazards during manufacturing or storage processes. Unlike CO2 purging, nitrogen is inert, non-reactive, and less soluble in liquids, making it ideal for preserving product integrity and safety. Your choice of nitrogen purging ensures a stable, oxygen-free environment critical for industries such as pharmaceuticals, food packaging, and electronics.

Key Differences Between CO2 and Nitrogen Purging

CO2 purging uses carbon dioxide to displace oxygen in storage or packaging, offering antimicrobial properties and reducing oxidation faster than nitrogen. Nitrogen purging provides an inert atmosphere by replacing oxygen with nitrogen gas, which is cost-effective and widely used for longer shelf life and preventing combustion. Your choice depends on applications requiring rapid oxidation control (CO2) versus maintaining inert conditions with minimal reactivity (nitrogen).

Applications of CO2 Purging

CO2 purging is widely used in food and beverage packaging to extend shelf life by displacing oxygen and inhibiting microbial growth. In the pharmaceutical industry, CO2 purging ensures a sterile environment by removing contaminants and moisture from packaging. It is also applied in metal casting to prevent oxidation during molten metal handling, enhancing product quality and durability.

Applications of Nitrogen Purging

Nitrogen purging is widely used in industries such as chemical processing, food packaging, and pharmaceuticals to prevent oxidation and contamination by displacing oxygen and moisture. Its inert properties make nitrogen ideal for creating an oxygen-free environment in pipelines, storage tanks, and reactors, ensuring product quality and safety. You benefit from nitrogen purging in processes requiring strict control of atmospheric conditions to extend shelf life and maintain product integrity.

Safety Considerations: CO2 vs Nitrogen

When comparing purge gases, CO2 and nitrogen differ significantly in safety profiles; CO2 poses risks of asphyxiation due to its density and ability to displace oxygen in confined spaces, requiring careful monitoring of oxygen levels. Nitrogen is inert and non-toxic but can similarly cause oxygen deficiency hazards if not managed properly, making adequate ventilation essential during purging operations. Your safety protocols should emphasize gas detection systems and proper ventilation regardless of whether CO2 or nitrogen is used as the purge gas.

Cost Comparison: CO2 vs Nitrogen Purging

CO2 purging generally offers a lower initial cost compared to nitrogen due to the widespread availability and lower production expenses of carbon dioxide. However, nitrogen purging tends to be more cost-effective over time because of its inert properties, which can reduce corrosion and equipment maintenance costs. Your choice depends on balancing upfront expenses with long-term operational savings and specific application requirements.

Environmental Impact of CO2 and Nitrogen

CO2 purging often utilizes captured carbon dioxide, which can reduce greenhouse gas emissions by repurposing industrial CO2, whereas nitrogen purging typically relies on nitrogen generated from air separation, resulting in minimal direct environmental emissions. The environmental impact of CO2 depends on its source and lifecycle, with recycled CO2 contributing to lower overall carbon footprints compared to fossil-based CO2 or nitrogen production through energy-intensive processes. You can minimize your environmental impact by choosing purging systems that optimize CO2 reuse or use nitrogen generated with renewable energy.

Choosing the Right Gas for Purging Operations

Selecting the right gas for purging operations depends on the specific application requirements such as chemical compatibility, safety, and cost efficiency. CO2 is often favored for its non-flammability and ability to displace oxygen effectively while providing cooling effects during purging. Nitrogen is widely used for its inertness, availability, and economical benefits, making it ideal for applications requiring an oxygen-free environment without cooling considerations.

Purge with CO2 vs nitrogen Infographic

libmatt.com

libmatt.com