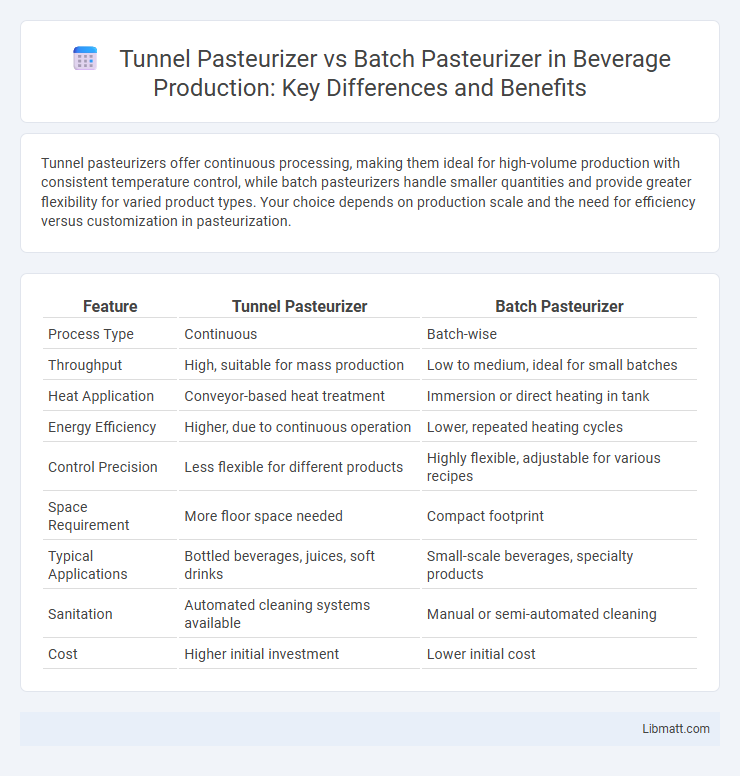

Tunnel pasteurizers offer continuous processing, making them ideal for high-volume production with consistent temperature control, while batch pasteurizers handle smaller quantities and provide greater flexibility for varied product types. Your choice depends on production scale and the need for efficiency versus customization in pasteurization.

Table of Comparison

| Feature | Tunnel Pasteurizer | Batch Pasteurizer |

|---|---|---|

| Process Type | Continuous | Batch-wise |

| Throughput | High, suitable for mass production | Low to medium, ideal for small batches |

| Heat Application | Conveyor-based heat treatment | Immersion or direct heating in tank |

| Energy Efficiency | Higher, due to continuous operation | Lower, repeated heating cycles |

| Control Precision | Less flexible for different products | Highly flexible, adjustable for various recipes |

| Space Requirement | More floor space needed | Compact footprint |

| Typical Applications | Bottled beverages, juices, soft drinks | Small-scale beverages, specialty products |

| Sanitation | Automated cleaning systems available | Manual or semi-automated cleaning |

| Cost | Higher initial investment | Lower initial cost |

Introduction to Pasteurization Methods

Tunnel pasteurizers offer continuous processing, efficiently heating products such as bottles or cans as they move through a controlled temperature tunnel, ensuring consistent microbial reduction and extended shelf life. Batch pasteurizers process products in fixed quantities, immersing containers in heated water or steam tanks, which is ideal for small-scale operations or products sensitive to rapid temperature changes. Understanding these pasteurization methods helps optimize your production line's efficiency and product quality based on volume demands and thermal sensitivity.

What is a Tunnel Pasteurizer?

A tunnel pasteurizer is a continuous heat treatment system designed to sterilize packaged beverages by passing them through a temperature-controlled water bath or steam tunnel, ensuring consistent pasteurization without interrupting production flow. It offers precise temperature regulation and high throughput, making it suitable for large-scale beverage manufacturing. Compared to batch pasteurizers, tunnel pasteurizers reduce processing time and improve energy efficiency while maintaining product quality and safety.

Understanding Batch Pasteurization

Batch pasteurization involves heating a fixed volume of liquid to a specific temperature for a set time before cooling, ensuring uniform microbial destruction. Unlike tunnel pasteurizers, which process continuously, batch pasteurizers offer greater control over small production runs and product testing. Your choice depends on production scale, with batch systems ideal for flexibility and maintaining product quality in smaller batches.

Key Differences Between Tunnel and Batch Pasteurizers

Tunnel pasteurizers provide continuous processing with higher throughput, ideal for large-scale beverage production, while batch pasteurizers operate in discrete cycles suitable for smaller volumes. Tunnel systems use conveyor belts to move products through controlled heat zones, ensuring consistent temperature exposure, whereas batch pasteurizers submerge product containers or circulate heated water in tanks. The choice depends on production scale, with tunnel pasteurizers offering efficiency and uniformity, and batch pasteurizers providing flexibility for varied product types.

Processing Efficiency Comparison

Tunnel pasteurizers offer higher processing efficiency than batch pasteurizers by enabling continuous product flow and faster throughput rates, making them ideal for large-scale operations. Batch pasteurizers operate in discrete cycles, which can slow down production and increase labor costs due to frequent loading and unloading. Your choice depends on volume needs, with tunnel pasteurizers providing greater automation and consistent heat application for more efficient pasteurization.

Product Quality and Consistency

Tunnel pasteurizers ensure superior product quality and consistency by providing continuous, uniform heat treatment with precise temperature control, reducing the risk of microbial contamination and spoilage. Batch pasteurizers, while effective, often experience variability in temperature distribution, leading to potential inconsistencies in product texture and taste. The tunnel process's automation and controlled environment result in reliable pathogen inactivation and extended shelf life, making it preferable for high-volume, quality-sensitive production.

Energy Consumption and Resource Use

Tunnel pasteurizers offer significantly lower energy consumption by continuously processing products, minimizing heat loss and optimizing steam and water use. Batch pasteurizers consume more energy due to repeated heating and cooling cycles for each batch, leading to higher water and steam usage. The continuous operation of tunnel pasteurizers also reduces resource waste, enhancing overall process efficiency.

Scalability and Production Volume

Tunnel pasteurizers offer superior scalability and higher production volumes by enabling continuous processing of large batches, making them ideal for high-demand operations. Batch pasteurizers, in contrast, handle smaller quantities in discrete batches, limiting throughput and scalability for growing production needs. Choosing the right pasteurizer depends on Your required volume and future expansion plans.

Cost Analysis: Installation and Operation

Tunnel pasteurizers typically require a higher initial installation cost due to their larger scale and automated systems, but they offer lower per-unit operational costs through continuous processing and energy efficiency. Batch pasteurizers involve lower upfront expenses and simpler installation, making them suitable for small-scale production, but they incur higher operational costs over time due to labor intensity and slower throughput. Your choice depends on production volume and budget, balancing installation investment against long-term operational savings.

Choosing the Right Pasteurizer for Your Industry

Tunnel pasteurizers offer continuous processing ideal for high-volume industries like beverage and canned food production, ensuring consistent temperature control and speed optimization. Batch pasteurizers suit smaller-scale operations or products requiring precise thermal treatment, providing flexibility for diverse formulations such as dairy or specialty sauces. Selecting the right pasteurizer depends on production capacity, product sensitivity, and process efficiency requirements to maximize quality and safety.

Tunnel pasteurizer vs batch pasteurizer Infographic

libmatt.com

libmatt.com