Saccharification is the enzymatic process that breaks down complex carbohydrates like starch into simple sugars, which serve as the essential substrates for fermentation. Your understanding of these processes helps optimize biofuel production by ensuring efficient sugar conversion before fermenting sugars into ethanol or other bio-products.

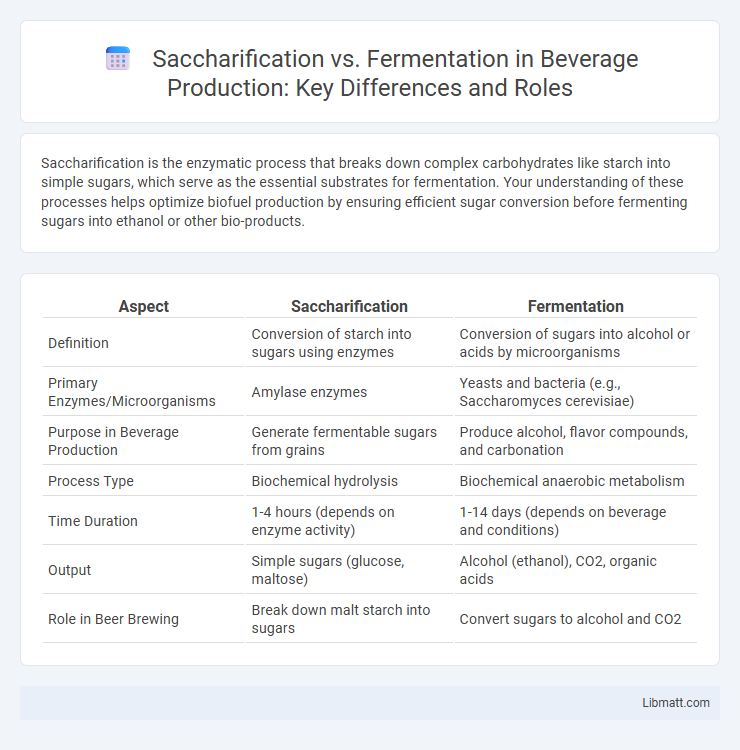

Table of Comparison

| Aspect | Saccharification | Fermentation |

|---|---|---|

| Definition | Conversion of starch into sugars using enzymes | Conversion of sugars into alcohol or acids by microorganisms |

| Primary Enzymes/Microorganisms | Amylase enzymes | Yeasts and bacteria (e.g., Saccharomyces cerevisiae) |

| Purpose in Beverage Production | Generate fermentable sugars from grains | Produce alcohol, flavor compounds, and carbonation |

| Process Type | Biochemical hydrolysis | Biochemical anaerobic metabolism |

| Time Duration | 1-4 hours (depends on enzyme activity) | 1-14 days (depends on beverage and conditions) |

| Output | Simple sugars (glucose, maltose) | Alcohol (ethanol), CO2, organic acids |

| Role in Beer Brewing | Break down malt starch into sugars | Convert sugars to alcohol and CO2 |

Introduction to Saccharification and Fermentation

Saccharification is the biochemical process where complex carbohydrates such as starch are broken down into simpler sugars like glucose using enzymes like amylase. Fermentation follows saccharification by converting these sugars into biofuels, alcohol, or organic acids through microbial activity, typically involving yeast or bacteria. Both processes are crucial in bioethanol production, where saccharification increases sugar availability and fermentation converts sugars into ethanol efficiently.

Defining Saccharification: Key Concepts

Saccharification is the biochemical process that breaks down complex carbohydrates like starch into simple sugars, primarily glucose, through enzymatic action. This step is crucial in biofuel production and food industries, as it prepares raw materials for fermentation, where sugars are converted into ethanol or other products. Understanding saccharification enables you to optimize the efficiency of subsequent fermentation by ensuring maximum sugar availability.

Fermentation Explained: An Overview

Fermentation is a metabolic process that converts sugars into alcohol or acids using yeast or bacteria, playing a crucial role in producing beverages, biofuels, and food products. Unlike saccharification, which breaks down complex carbohydrates into fermentable sugars, fermentation transforms those sugars into energy and valuable end products like ethanol or lactic acid. Your understanding of fermentation helps optimize industrial processes by controlling factors such as temperature, pH, and microbial activity to maximize yield and quality.

Biological Basis of Saccharification

Saccharification is the enzymatic process where complex carbohydrates like starch or cellulose are broken down into simpler sugars, primarily glucose, through the action of enzymes such as amylases and cellulases. This biological basis involves microorganisms or plant-derived enzymes catalyzing the hydrolysis of glycosidic bonds, converting polysaccharides into fermentable sugars. Understanding saccharification is crucial for optimizing biofuel production or brewing, as it directly influences the efficiency of subsequent fermentation stages that convert these sugars into ethanol or other valuable products.

Microorganisms Involved in Fermentation

Fermentation primarily involves microorganisms such as yeast and bacteria, with Saccharomyces cerevisiae being the most common yeast used for alcohol production. In contrast, saccharification relies on enzymes like amylase and cellulase to break down complex carbohydrates into simple sugars before fermentation. Your understanding of these microorganisms is crucial for optimizing fermentation processes and improving product yield in bioethanol or food industries.

Key Enzymes in Saccharification Processes

Key enzymes in saccharification processes include amylases, cellulases, and b-glucosidases, which break down complex carbohydrates into fermentable sugars. Amylases hydrolyze starch into maltose and glucose, cellulases degrade cellulose into cellobiose and glucose, and b-glucosidases convert cellobiose to glucose, facilitating efficient sugar release. The efficiency and specificity of these enzymes directly impact the yield and rate of saccharification, critical for subsequent fermentation steps.

Industrial Applications: Saccharification vs Fermentation

Saccharification and fermentation serve distinct roles in industrial applications, with saccharification involving the enzymatic breakdown of complex carbohydrates into simple sugars, which is critical in biofuel production and food processing. Fermentation converts these sugars into valuable products like ethanol, organic acids, and pharmaceuticals, making it essential for industries such as brewing, biotechnology, and renewable energy. Your choice between saccharification and fermentation depends on the desired end product, as both processes are often integrated for efficient biomass conversion and enhanced yield.

Advantages and Limitations of Each Process

Saccharification converts complex carbohydrates into simple sugars, enabling efficient sugar recovery for downstream applications but requires precise enzymatic control and can be time-consuming. Fermentation transforms these simple sugars into desired bio-products like ethanol or organic acids, offering renewable production routes yet facing challenges such as microbial sensitivity and potential byproduct formation. Optimizing saccharification enhances substrate availability, while fermentation efficiency depends on strain selection and process conditions, highlighting the complementary nature and trade-offs of both techniques.

Comparative Analysis: Saccharification vs Fermentation

Saccharification involves the enzymatic breakdown of complex carbohydrates like starch into simple sugars such as glucose, whereas fermentation converts these sugars into ethanol, organic acids, or gases using microorganisms like yeast or bacteria. Saccharification is critical in biofuel production and food processing by providing fermentable substrates, while fermentation completes the biochemical conversion yielding bioethanol, lactic acid, or other metabolic products. The efficiency of saccharification directly impacts fermentation yield, making their optimization essential in industrial biotechnology applications.

Future Trends in Bioconversion Technologies

Future trends in bioconversion technologies emphasize integrated saccharification and fermentation (SSF) processes to enhance bioethanol production efficiency by reducing enzyme inhibition and process time. Advances in enzyme engineering and microbial strain development are improving saccharification rates and fermentation yields, enabling cost-effective biomass-to-biofuel conversion. Emerging bioreactor designs and process optimization strategies are driving scalable, sustainable biofuel production with lower environmental impact.

Saccharification vs fermentation Infographic

libmatt.com

libmatt.com